12

Translation of the original operation manual Airless

Phoenix_BAoDB_en_1210

•

jw

4

Installation and Assembly

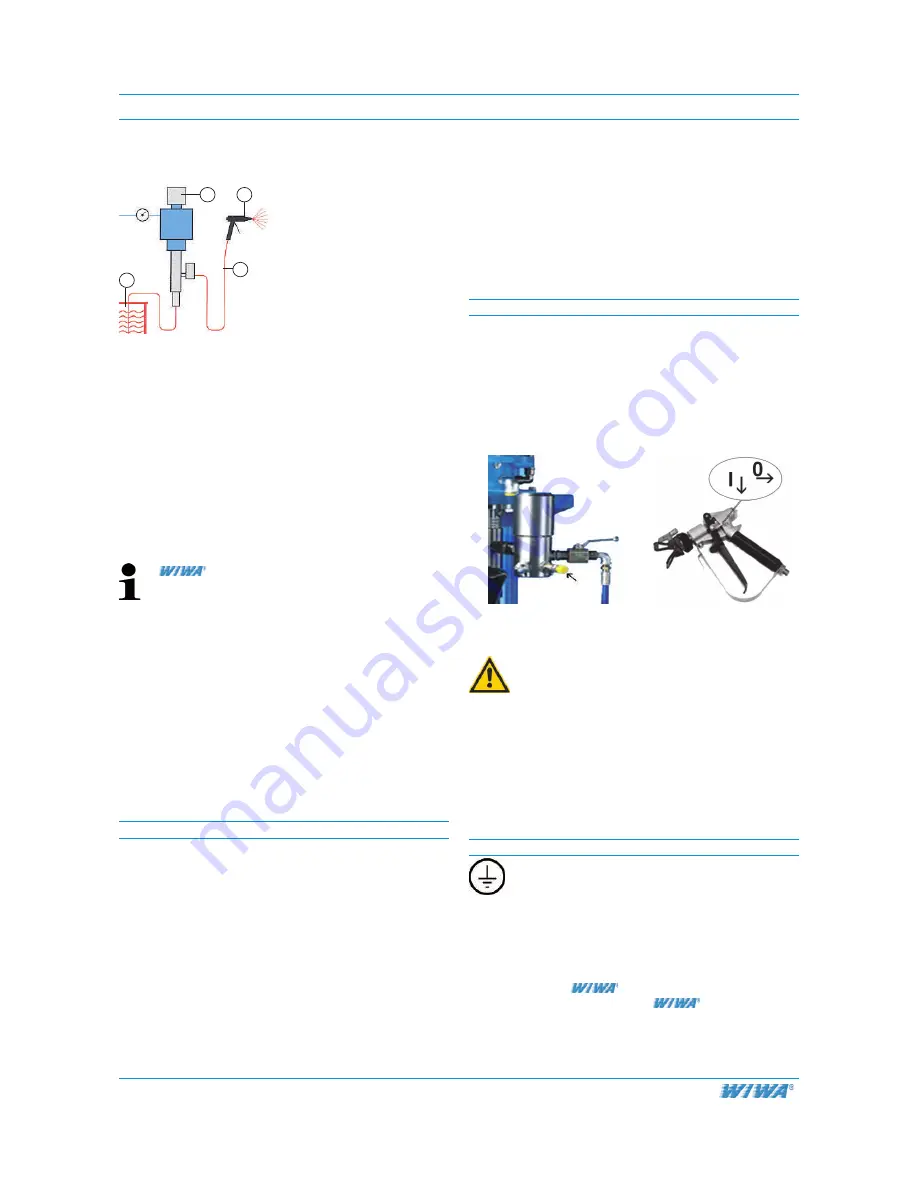

1 Airless unit

2 Airless spray gun

3 Paint container

4 Spray hose

Picure 4.1

1

2

3

4

Job

The unit is to be installed at the job site and prepared for

operation.

Prerequisite

➤

The material to be worked with is prepared.

➤

All materials to be sprayed should be marked with

information on viscosity, processing temperatures,

mixing proportions etc. If this is not the case, please

acquire this data from the relevant manufacturer.

➤

The material to be sprayed must be slowly but tho-

roughly stirred before beginning to work.

offers a broad selection of accesso-

ries for the optimised preparation of spraying

materials, i.e.:

➤

agitators in various sizes

➤

material pre-heating containers in various

sizes

➤

fluid hester

If working with plural component materials,

the pot life must be observed.

➤

To insure that the necessary volume of air is supplied,

the compressor capacity must comply with the air con-

sumption requirements of the pump.

The diameter of the air supply hoses must correspond

to the connection on the pump.

1. Set up the pump

➤

The pump must be set up securely on a level and solid

surface

➤

Pay attention to the information covering the required

floor space found in machin card.

➤

Operating elements must be easily accessible

➤

Safety features must be

easily accessible

Wall-mounted versions:

➤

To fix the wall-mount, use M 12 screws - class 8.8

➤

Be sure to use anchoring devices in accordance with

the nature of the wall being used

➤

Ensure that at least 10 cm (4 in.) free space is left

between the suction elbow and the floor after mounting

(refer to the picture in Chapter 3)

2. Mount accessories

For transport purposes the following components were

dismounted and packed in a separate carton:

1.

Spray hose (Picture 4.2)

2.

Airless spray gun (Picture 4.3)

3.

Air regulator or maintenance unit (depending upon

version)

➤

Attach these items according to Picture 4.2 + 4.3.

Note:

The air maintenance unit is connected to the air

inlet of the air motor.

Picture 4.2 Spray hose con

-

nection on the high-pressure

filter

Picture 4.3 Spray hose con

-

nection to the spray gun

m

Warning!

Material leaks at connections can lead to se-

rious injury of property damage.

Check all turnable parts, nuts, screws and

hose connections and tighten them securely.

➤

Check the permissible maximum air pressure for the

spray hose, spray gun and accessories. It must be

greater than or equal to the maximum operational

pressure shown on the pump's nameplate or on the

machine card.

3 Ground the unit

Warning!

Due to the high flow speed created by Airless

equipment, static charging can occur. A static

charge can lead to fires or explosion

A static charge can lead to fires or explosion.

➤

The pump and object to be coated must be

grounded properly

➤

Only use conductive hoses

Note:

spray hoses are conductive

and compatible with

pumps