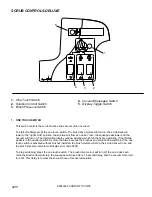

SCRUB CONTROLS-SQUEEGEE

86037660 CHARIOT 11/09/06

3-14

1. SQUEEGEE DEFLECTION ADJUSTMENT

KNOBS

Adjusts the deflection along the entire length of

the squeegee.

To increase squeegee blade deflection, turn the

two knobs at the ends of the squeegee

counterclockwise.

To decrease squeegee deflection, turn the two

knobs at the ends of the squeegee clockwise.

2. SQUEEGEE PITCH ADJUSTMENT ROD

(DISK SCRUBBER)

Adjusts the deflection at the ends of the

squeegee.

To increase squeegee blade deflection at the

ends, turn rod counterclockwise.

To decrease squeegee blade deflection at the

ends, turn rod clockwise.

SQUEEGEE PITCH ADJUSTMENT KNOB

(CYLINDRICAL)

Adjusts the deflection at the ends of the

squeegee.

To increase squeegee blade deflection at the

ends, turn knob counterclockwise.

To decrease squeegee blade deflection at the

ends, turn knob clockwise.