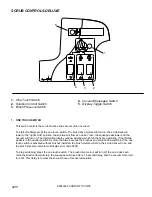

HOW THIS MACHINE WORKS

86037660 CHARIOT 11/09/06

3-3

The Chariot® is a battery powered, self-propelled,

hard floor scrubber intended for commercial use.

The appliance applies a cleaning solution onto a

hard floor, scrubs the floor with brushes, and then

vacuums the soiled water back into the recovery

tank.

The machine's primary systems are the solution

system, scrub system, recovery system, and

operator control system.

The function of the solution system is to store

cleaning solution and deliver it to the scrub system.

The solution system consists of the solution tank,

strainer, pump, valve and controls. The solution

tank stores cleaning solution (water and detergent)

until it is delivered to the scrub system. The strainer

protects the pump from debris. The valve

automatically prevents solution flow unless the scrub

brushes are turned on and the machine is being

propelled. The solution control switch controls the

amount of cleaning solution delivered to the scrub

system by controlling the amount of time the pump is

on.

The function of the scrub system is to scrub the

floor. The disk scrub system consists of two rotary

type disk scrub brushes, motors, scrub deck skirt, lift

actuator and controls. The brushes scrub the floor

as the motors drive the brushes. The brush drive

hubs allow the scrub brushes to follow irregularities

and changes in the floor without loosing contact with

the floor. The scrub deck skirts control the cleaning

solution on the floor so that the squeegee can pick it

up. The one touch/brush switch controls the motors

and lift actuator to turn the motors on and lower the

deck, or turn the motors off and raise the deck. The

brush pressure switch controls the down pressure

on the scrub deck.

The scrub plus system consists of two cylindrical

type brushes, motors, scrub deck side squeegees,

hopper, lift actuator, and controls. The cylindrical

scrub head is designed to eliminate debris that may

be caught in the squeegee while scrubbing. Water

is applied to the first scrubbing brush turning in a

clockwise rotation when viewed from the right side of

machine. The first brush scrubs dirt and debris

between the brushes. The second scrubbing brush,

turning in a counter clockwise rotation, picks up

debris and throws it into a removable hopper. Water

is allowed to drain out the hopper into the squeegee

path where it is recovered from the floor.

The scrub deck side squeegees control the cleaning

solution on the floor so that the squeegee can pick it

up. The brush pressure switch controls the motors

and lift actuator to turn the motors on and lower the

deck, or turn the motors off and raise the deck. The

brush pressure switch also controls the down

pressure on the scrub deck.

The function of the recovery system is to vacuum

the soiled water back into the recovery tank. The

recovery system consists of the squeegee, vacuum

motor, float ball filter, recovery bag and controls.

The squeegee wipes the dirty solution off the floor

as the machine moves forward. The vacuum motor

provides suction to draw the dirty solution off the

floor and into the recovery bag. The float ball filter

protects the vacuum fan from debris and foam. The

recovery bag stores the dirty solution.

The function of the operator control system is to

control the direction and speed of the machine. The

directional control system consists of the direction

control switch, throttle pedal, operator presence

pedal, speed control switch, drive reset switch,

emergency stop/brake switch, steering wheel, propel

controller, and drive wheel. The directional control

switch signals forward or reverse direction. The

controller interprets signals from the throttle pedal to

command the drive wheel to propel or slow the

machine. The drive reset switch is to make sure the

operator is on platform before machine will propel.

The operator presence pedal is to make sure the

operator keeps both feet safely on platform while

driving. The steering wheel points the drive wheel in

the direction desired by the operator. The parking

brake automatically engages when the operator

steps off the platform. The emergency stop/brake

can be used to hold the machine on slopes.