9

Wilo-ICL - Installation and Operation Manual

8.

8.1

Fill and Ventilate

Ventilate

6.2.5

Caution: Damage due to overheating!

For insulated piping systems, only the pump volute

may be insulated, not the lantern and the motor. These

could be damaged by heat build-up.

9.

10.

10.1

10.2

Maintenance and Repair

Cleaning

Clean the exterior of the pump using only a

lightly damp-ened cloth without detergents.

Checks

Under normal operating conditions, the pump

does not require regular maintenance work. The

following points, however, must be checked at

regular intervals.

Warning: Danger due to hot liquid under pressure!

Extreme caution must be used when venting systems

that have elevated temperatures and/or dangerous

fluids. Maintain sufficient distance from the air vent

opening. Wear suitable clothing including protective

glasses/facial protection and gloves.

Caution: Damage due to cavitation!

Failing to maintain minimum pressure on the suction

side can to lead to cavitation accompanied by noise.

This can damage the pump. This minimum inlet

pressure depends on the operating conditions and

the duty point of the pump and must be calculated

accordingly. Please contact WILO or your WILO

distributor if this information is required.

8.2

8.3

1.

2.

3.

4.

5.

6.

7.

Open air vent valve (1) 1/2 turn, do not remove.

Completely open suction side and discharge

side isolation valves.

Wait until the liquid has exited the ventilation

opening and until bubbles no longer form.

Tightly close the ventilation opening.

Avoid Cavitation

Ensure that the minimum pressure stipulated

in the product catalog is present on the suction

side.

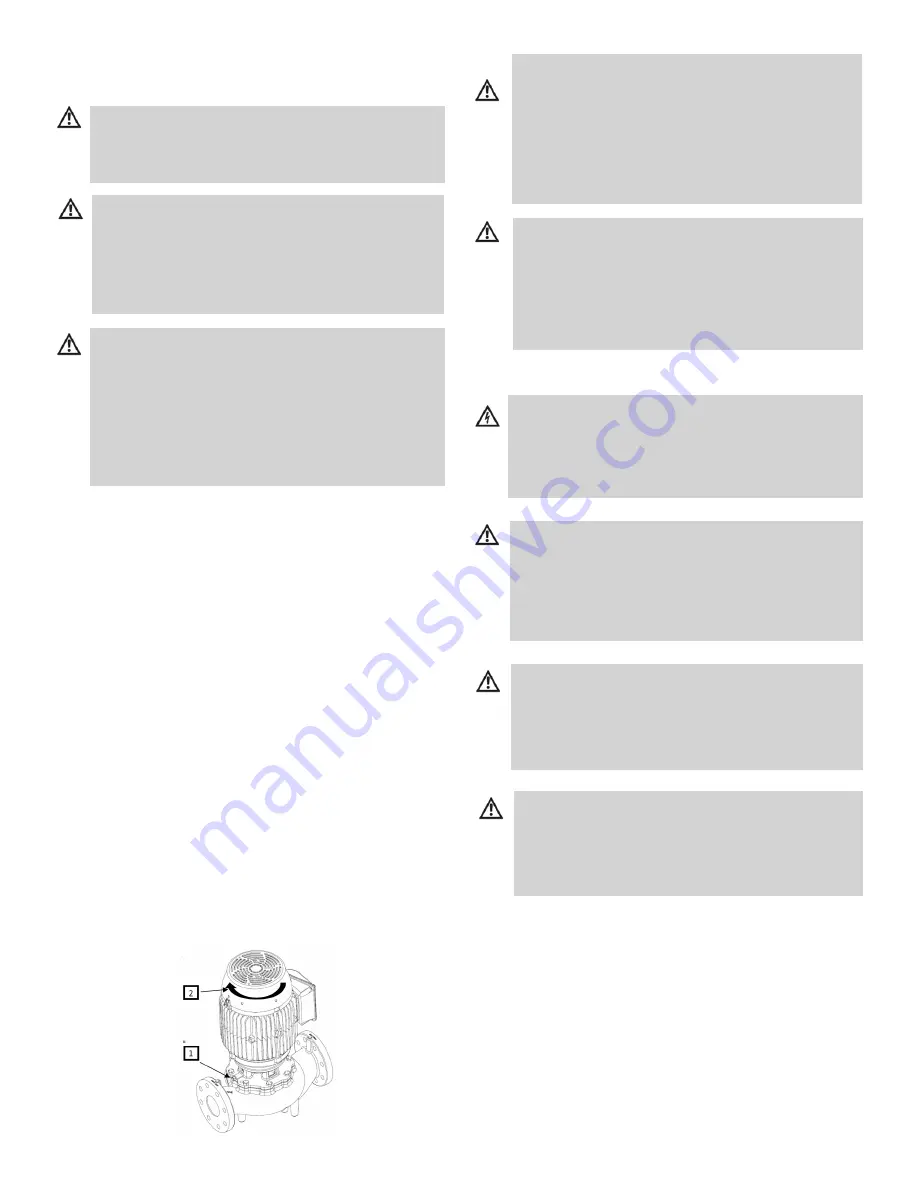

Check Direction of Rotation

Check the motor’s direction of rotation by

briefly turning it on. The direction of rotation is

correct if the fan or other visibly rotating parts

of the pump are rotating in the direction of the

arrow (2).

* On three phase only, if the direction of

rotation is incorrect, have an electrician correct

it by swapping two phases.

Turn on the pump for test operation and

observe whether it is pumping correctly. If

necessary, ventilate again until a sufficient

pumping result is achieved.

Operation

Warning: Risk of burning or freezing if the pump is

touched!

Depending on the operating conditions of the pump

or installation (liquid temperature), the entire pump

can become very hot or very cold. Keep your distance

during pump operation!

Caution: Damage due to overheating!

The pump may not be operated longer than 1 minute

without flow. An accumulation of energy creates

heat that can damage the pump shaft, impeller and

mechanical seal. A minimum flow rate of approx. 10%

of maximum flow rate must always be guaranteed.

Danger: Life threatening due to electrical shock!

Touching live components can be fatal. Only qualified

electricians may work on the electrical system. Prior to

any maintenance work, disconnect the pump from the

power supply and secure against reconnection.

Warning: Damage due to incorrectly tightened

screws!

Overtightened screws can break off. Subsequently,

separate parts and fragments may chip off and / or the

hot liquid may spray. Observe screw tightening torque

specifications L Page 11

Warning: Danger due to hot liquid under pressure!

During dismantling of motor or pump, hot liquids may

escape under high pressure. Allow the pump to cool

down first. Close isolation valve prior to dismantling

pump.

Caution: Damage due to incorrectly performed

maintenance!

Incorrectly performed maintenance work can damage

the pump. The maintenance work described below

may therefore only be performed by trained personel.