8

WILO_IOM_ICL_1219

6.

7.

If desired, a condensate drain can be connected.

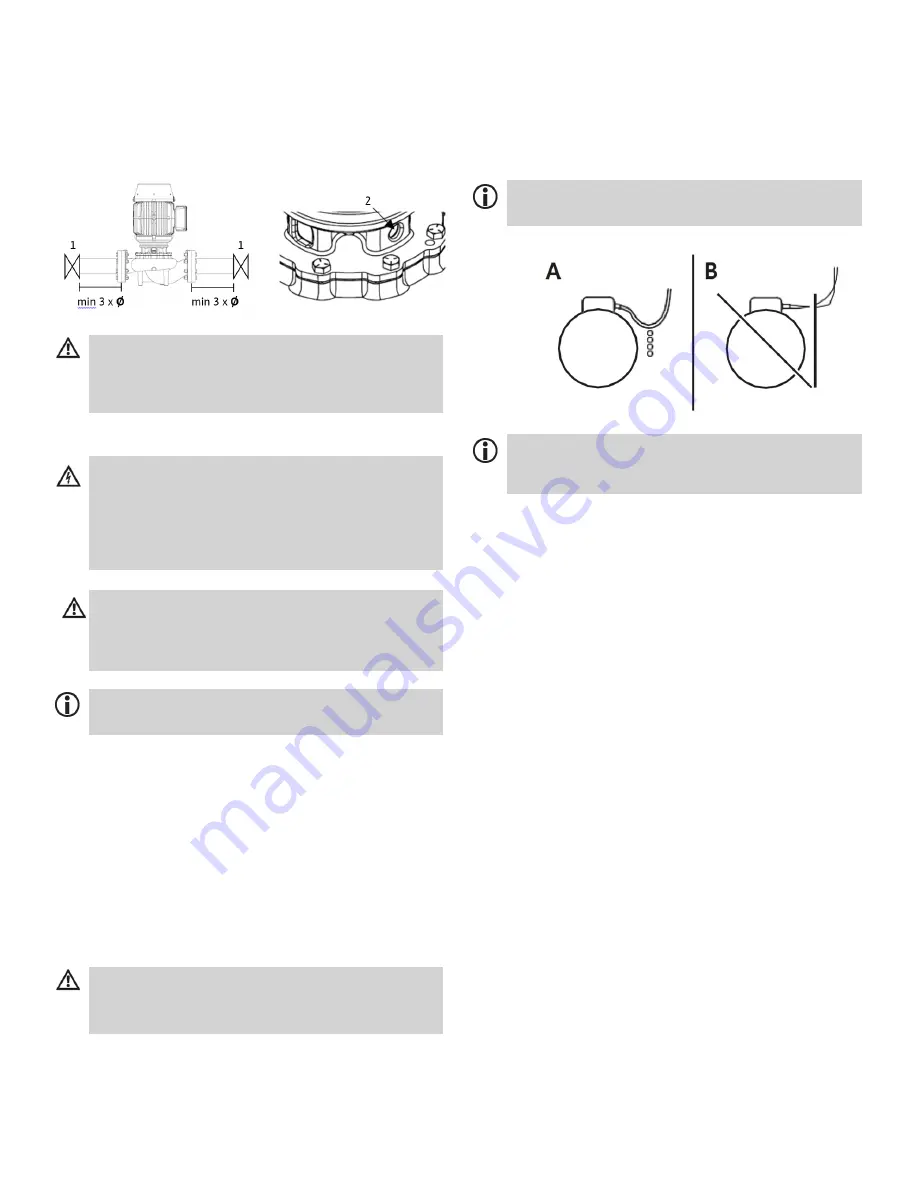

(2) Condensate drain for vertical installation

position of the motor

Seal up unused condensate drain.

7.

Electrical Connection

Caution: Damage due to overheating!

For insulated piping systems, only the pump volute

may be insulated, not the lantern and the motor. These

could be damaged by heat build-up.

Danger: Life threatening due to electrical shock!

Touching live parts can be fatal. Work on the electrical

connection may only be performed by a trained

electrician. Prior to connecting, ensure that the

connecting line is voltage-free.

7.1

Electrical Connection

1.

Connect the connecting cable with power

switched off and secure against reconnection.

2.

Lay the connecting cable such that it doesn’t

come into contact with the pump, the pump

housing, or the piping.

3.

Check whether the voltage and amperage in

the mains match the specifications on the type

plate of the pump.

Warning: Danger due to a damaged cable!

For pumps that pump hot liquids or that are used in

proximity to hot surfaces with temperatures above

194°F [90°C], a heat- resistant cable must be used.

Note:

For the correct cable size, refer to local wiring

restrictions.

Caution: Damage due to incorrect voltage!

Never operate the pump with incorrect voltage. This

could damage the motor.

6.

7.

Connect grounding cable.

Install motor control, cabling, overload

protection, mains circuit breaker and

accessories in accordance with the locally

applicable safety regulations.

4.

Open the terminal box.

5.

Lay the cable such that no condensation or

spray water can make contact with the cable

screws (Fig. A).

Note:

The connection diagram is located on an exterior

label or inside the terminal box.

Note:

Special motors can be supplied with a PTC

thermal sensor that must be connected to the PTC trip

relay.

8.

9.

10.

11.

7.1.1

To protect the motor, overheating protection

should also be installed.

Tighten cable screws

Close terminal box and ensure that no spraying

water can enter it.

Low temperature applications (below normal

temperature range) can be used with Glycol up

to a 50% concentration.

Caution when connecting to an automatic

pump control device

Comply with respective installation and

operating instruc- tions when wiring to

automatic pump control device (DDC or Building

Management Systems). Be sure the following

guidelines are met:

*AC power is within ±10% of rated voltage

with rated frequency (see motor name plate for

ratings)

or

*AC power is within ±5% of rated frequency

with rated voltage

or

*Combined variation in voltage and frequency

of ±10% (sum of absolute values) of rated

values, provided the frequency variation does

not exceed ±5% of rated frequency