Start-Up Procedure

Check the heater operation as outlined in the following instructions. If

any sparking, odors or unusual noises are encountered, shut off electric

power immediately. Recheck for wiring errors, or obstructions in or

near fan motor (if equipped).

Check Gas Input and Pressures

For heaters located at elevations between sea level and 4,500 feet, the

measured input must not be greater than the input shown on the rating

plate of the furnace. For elevations above 4,500 feet, the measured

input must not exceed the input of the rating plate reduced by 4 percent

for each 1,000 feet that the heater is above sea level.

Gas supply pressure and manifold pressure with the burner operating

must also be as specified on the rating plate.

Rated input will be obtained on the heating valve of 2510 Btu/hr for

propane at 10.5-inches manifold pressure and factory-sized orifices. If

L.P. Gas having a different heating value is supplied, orifices must be

changed by a qualified service technician before the heater is operated.

Check the Manifold Gas Pressure

A tapped opening is provided in the gas valve to facilitate measuring the

manifold gas pressure. A “U Tube” manometer having a scale range

from 0 to 12 inches of water should be used for this measurement. The

manifold pressure must be measured with the burner and pilot operating.

Any major changes in the flow must be made by changing the size of the

burner orifice.

Check Thermostat

Check thermostat operation. When set above room temperature or

temperature shown on the thermostat, the main burner should light.

Make certain the thermostat turns off the heater when room temperature

reaches the selected setting and starts the heater when room

temperature falls a few degrees.

Check the Gas Input (Natural Gas Only)

Under-firing could cause inadequate heat, excessive condensation or

ignition problems. Over-firing could cause shooting flame impingement

or overheating of the combustion chamber.

Before starting natural gas input check, obtain heating value of gas (BTU

per cubic foot) at standard conditions from your local supplier.

To measure the input using the gas meter, proceed as follows:

Step 1: Turn off gas supply to all other appliances except the heater.

Step 2: With the heater operating, time the smallest dial on the meter for

one complete revolution. If this is a 2 cubic foot dial, use the time in

seconds as is. (3,600 = Sec. Per Hr.) This gives the seconds per cubic

foot of gas being delivered to the heater.

Step 3: Assuming natural gas with a heating value of 1,000 Btu per

cubic foot and 34 seconds per cubic foot as determined by Step 2 then,

input: 1,000 x 3,600 34 = 106,000 Btu Per hour. This measured input

must not be greater than the input indicated on the rating plate of the

heater.

Step 4: Relight all other appliances turned off in Step 1 above and verify

all pilot burners are operating.

Warning

Warning

Danger of property damage, bodily injury or death.

Liquified petroleum (L.P.) gas is heavier than air and it will

settle in any low area, including open depressions and it

will remain there unless area is ventilated. Never attempt

start-up of unit before throughly ventilating area.

Type of Gas

Natural

L.P.

Manifold Pressure, In. W.C.

4”

10.5”

Natural gas heating value (Btu per cubic foot) can vary

significantly; therefore, it is the installer’s responsibility to see that

the Btu input to the heater is adjusted properly. Failure to do so

could cause combustion chamber failure, asphyxiation, fire or

explosion, resulting in property damage, bodily injury or death.

Refer to the National Fuel Code (NFPA-54) to be sure the heater

is burning fuel at the proper rate.

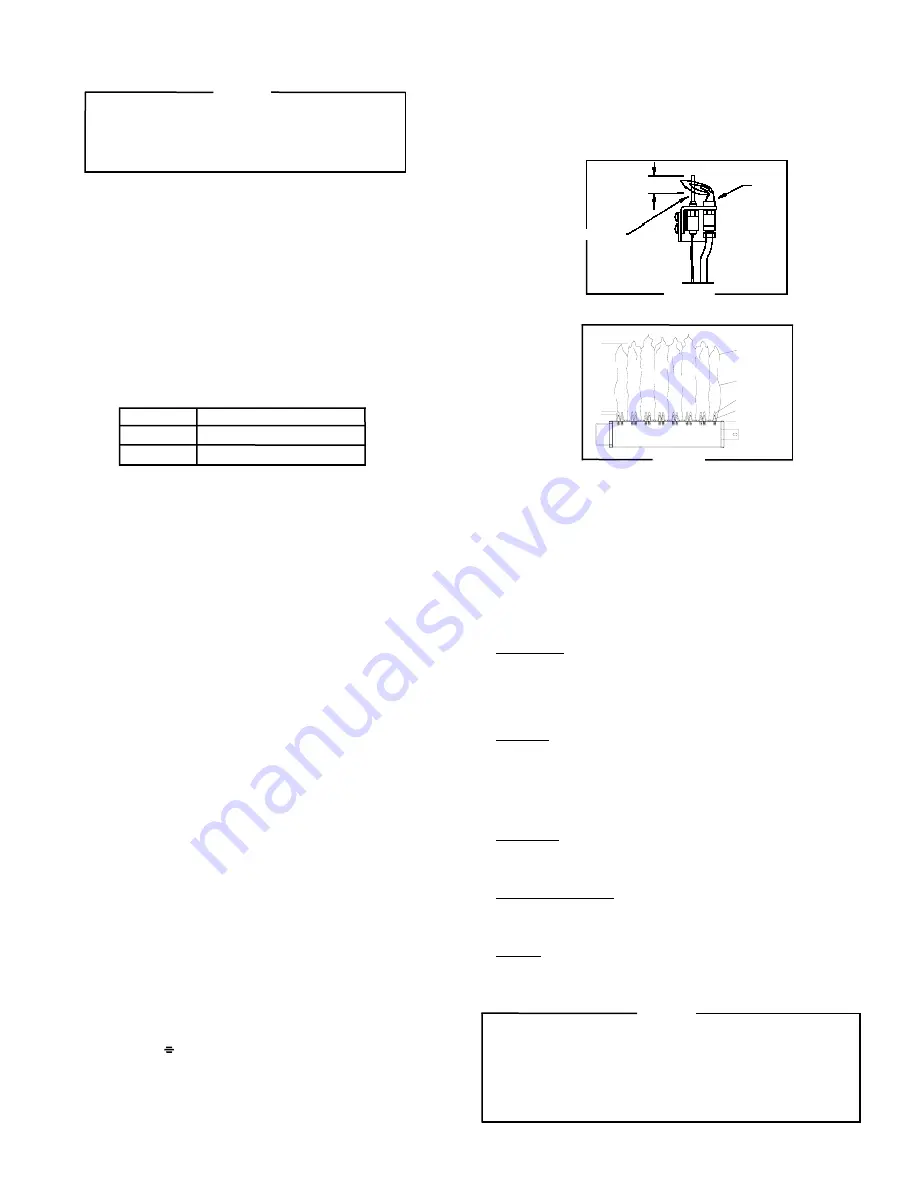

Figure 7

Figure 8

1/2 TO 5/8

INCH

PILOT

FRONT

VIEW

GENERATOR

Burner Flame Characteristics

Start the furnace and let it operate at least 10 minutes. Open the

access door to view the burner flame. Limit your movements near

the furnace a few more minutes before making your final

observations. The flame may look yellow due to dust particles in

the room air. The flame should change to a nice blue color with firm

inner and secondary cones. An occasional flash of orange might be

seen as dust particles burn in the flame. This is normal. No burner

adjustment is provided, or is necessary. (Figure 8).

Normal Appearance

Natural Gas:

1. Inner cone - blue color - 3/8 to 5/8 inch above ports

2. Secondary inner cone - light blue - 1 to 2 inches above ports

3. Total flame - from blue to nearly invisible - approximately 6 inches

above ports.

L.P. Gas:

1. Inner cone - blue color - 1/2 to 3/4 inch above ports.

2. Secondary inner cone - light blue - 1 to 2 inches above ports.

3. Total flame - from blue to nearly invisible - approximately 6

inches above ports.

Abnormal Appearance

Lazy Flame

Long soft yellow cones moving around in the combustion chamber

lifting from ports (insufficient air).

Extremely Fast Flame

Will not hold to ports - entire cone sections blow off from noisy ports

(too much pressure).

Warning

If flame appears abnormal, contact the gas company or a qualified

service technician immediately.

Check Pilot Burner

The pilot flame must envelop 1/2- to 5/8-inches of the generator.

Pilot flame is preset at the factory, so ordinarily does not require field

adjustment. (Figure 7). On new installations, the gas lines will be

filled with air and may take several minutes to establish a pilot flame.

3

2

1

NEARLY

PALE BLUE

LIGHT BLUE

BLUE

PORT LEVEL

ROUND STAINLESS STEEL

BURNER BODY

INVISIBLE

10

Summary of Contents for 2001621

Page 17: ...16 Enclosed Front...

Page 19: ...Fireplace Look with Logs 18...