25

Error Code Analysis

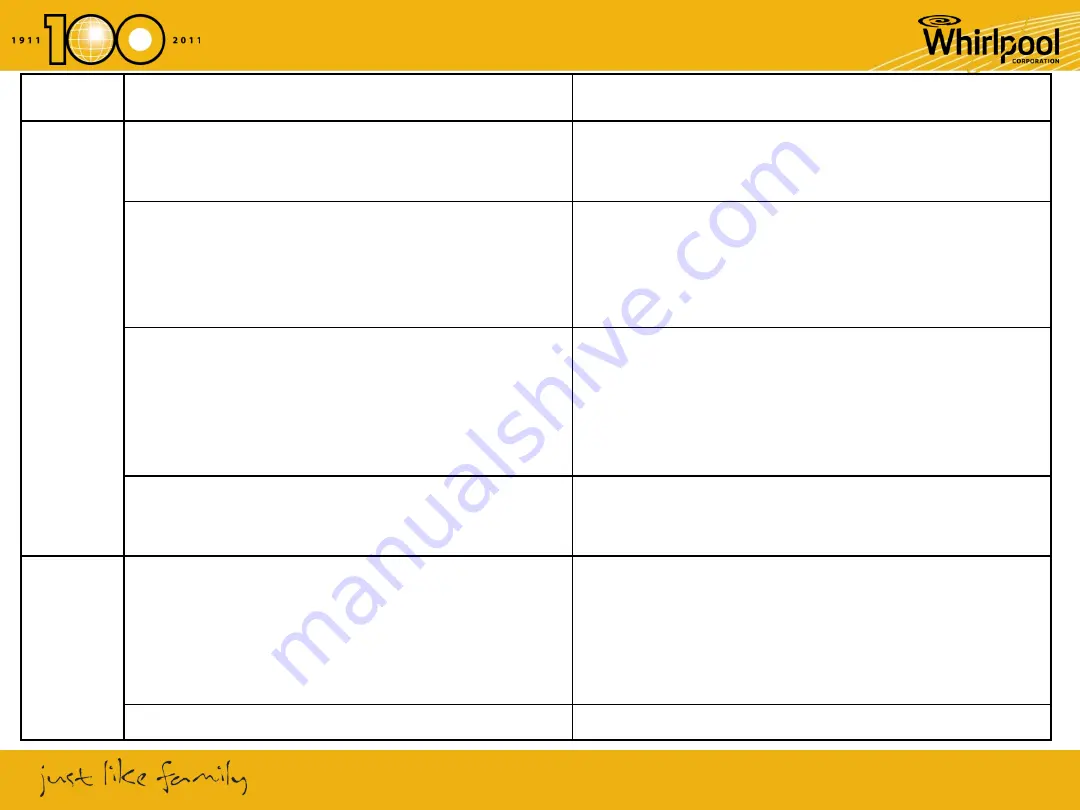

Fault

Description

Cause Analysis

Processing Method

F0

Upon turning ON, fan motor does not

turn, this may mean that the motor is broken

Testing the motor winding resistance is normal, if the nor

mal please plug again two butt plugs, if abnormal, please

replace the motor.

Without the zero signal

Reference indoor machine circuit diagram to ensure zero

crossing detection circuits without welding, welding, cont

rol circuit diagram tagging model of device parameters

such as resistance, voltage measurement, if the device is

damaged, please replace the same type of device.

No control signal

Reference indoor machine circuit diagram to ensure that

PG motor control circuit device without welding, welding,

control circuit diagram tagging model of device

parameters such as resistance, voltage measurement, if

the device is damaged, please replace the same type of

device.

Fan motor short running after the F0, which indicates

that the motor feedback signal wire broken, no feedb

ack signal

Turn the motor measurement feedback line 1/2 feet

without output, motor is bad, replace the motor.

F1-F5

Reference indoor machine circuit diagram to ensure

that PG feedback circuit device without welding,

welding, control circuit diagram tagging model of

device parameters such as resistance, voltage

measurement, if the device is damaged, please

replace the same type of device.

To insert the terminal socket, accordingly to ensure good

contact

Poor contact sensor socket

Replacement of the same model sensor

Summary of Contents for SIA120 IN

Page 14: ...14 Remote Control Functions ...

Page 19: ...19 Basic Functional Parts ...

Page 20: ...20 Sensor Location Evaporator Temperature Sensor Actual Room Temperature Ambient Sensor ...

Page 22: ...22 Basic Troubleshooting ...

Page 23: ...23 Basic Troubleshooting ...

Page 30: ...30 Thank You ...