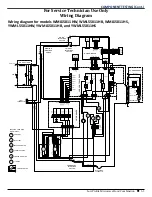

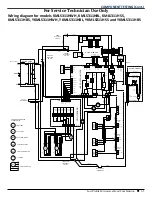

For Service Technician Use Only

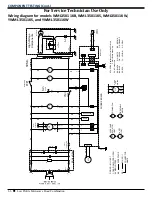

COMPONENT TESTING (Cont.)

3-2

n

Low Profile Microwave Hood Combination

Safety

DANGER

Electrical Shock Hazard

Only authorized technicians should perform

diagnostic voltage measurements.

After performing voltage measurements,

disconnect power before servicing.

Failure to follow these instructions can result in

death or electrical shock.

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Failure to do so can result in death or

electrical shock.

Replace all parts and panels before operating.

Voltage Measurement Safety Information

When performing live voltage measurements, you must do the following:

■

Verify the controls are in the off position so that the appliance does not start when energized.

■

Allow enough space to perform the voltage measurements without obstructions.

■

Keep other people a safe distance away from the appliance to prevent potential injury.

■

Always use the proper testing equipment.

■

After voltage measurements, always disconnect power before servicing.

Caution

: Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation.

Verify proper operation after servicing.