MAX Loaders

10

WESTENDORFMFG RR315270

Westendorf Manufacturing Co., Inc.

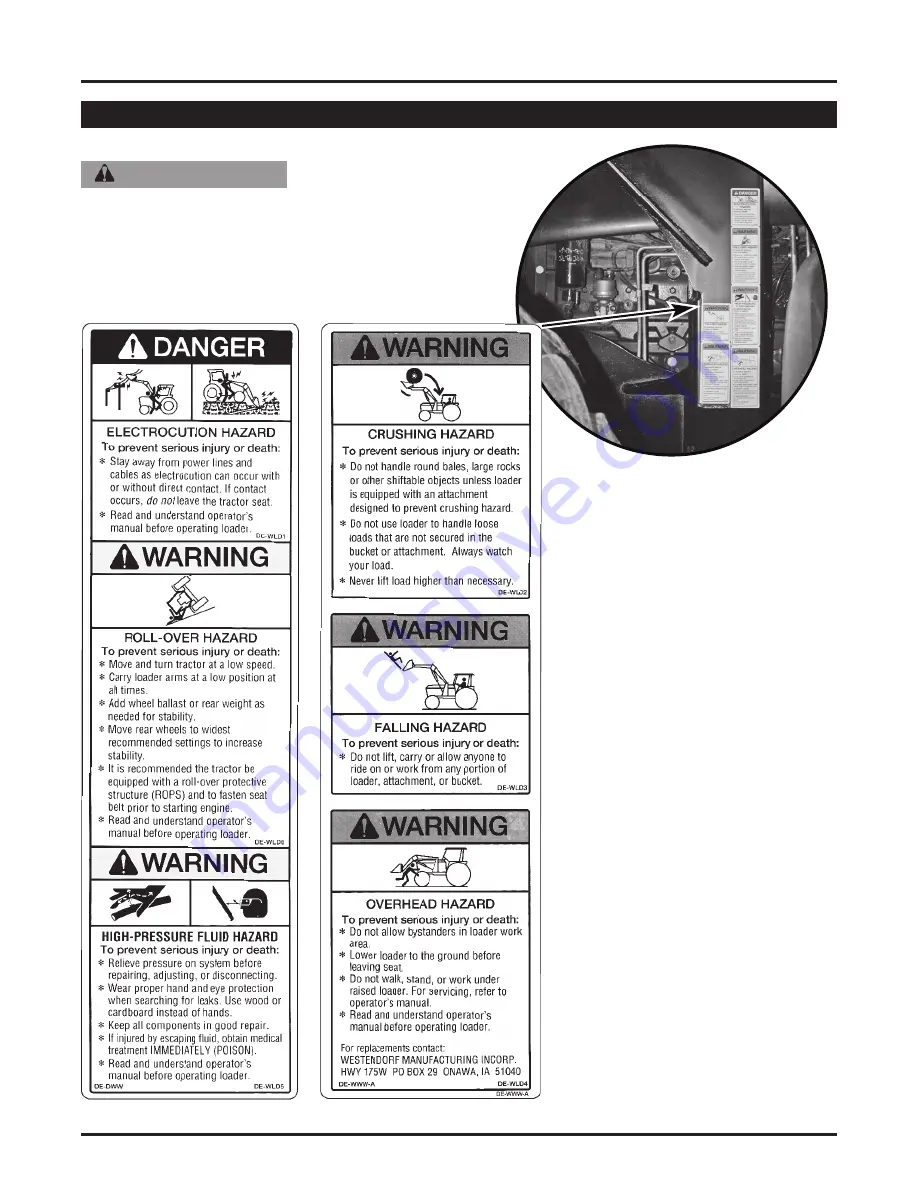

SAFETY DECAL

LOCATION

These decals are located on

the loader and attachments.

If any decals become damaged

or illegible you can order

replacements, free of charge,

by writing to:

Westendorf Mfg. Co., Inc.

PO Box 29

Onawa, IA 51040-0029

SAFETY DECALS

.

To protect you and others against death and serious injury:

• All decals shown must be on the loader

• Safety decals must be legible

• Replacement all worn or illegible decals immediately

• Provide us with the number shown at bottom of label.

WARNING

SECTION 2: SAFETY

Safety Decal Locations

LEFT SIDE MOUNTING BRACKET