ASSEMBLY

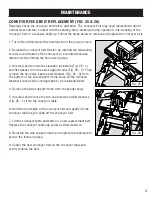

MOUNTING THE MACHINE ONTO THE STAND (FIG. 5)

1. This sander weighs over 150 lbs, so you will need a strong

muscular friend (or a trustworthy foe) to help you lift it up.

Carefully place the sander onto the assembled stand in the

orientation you prefer (the motor side of the sander can be

positioned above the wheels side or the handles side).

2. Align the mounting holes on the base of the machine with

the holes on the stand. Mount the machine in place using (4)

M10-1.5 x 30 hex bolts, (4) 10mm flat washers, and (4)

M10-1.5 hex nuts. Tighten the fasteners using a wrench.

NOTE:

If necessary to align the mounting holes, you can

slightly loosen the stand fasteners. Be sure to re-tighten them

after securing the sander assembly.

INSTALLING THE HEIGHT ADJUSTMENT WHEEL (FIG. 6)

Attach the height adjustment wheel onto the screw on top

of the sander. Mount the 12mm large washer and M12-1.75

acorn nut on top of the wheel and tighten the nut.

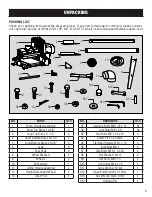

Drum Sander

Assembly (x1)

M10-1.5 x 30

Hex Bolts (x4)

10mm Flat

Washers (x4)

M10-1.5 x 30

Hex Nut (x4)

12mm Large

Washer (x1)

M12-1.75 Acorn

Nut (x1)

Height Adjustment

Wheel Assembly (x1)

Fig. 5

Fig. 6

12

Summary of Contents for 65911

Page 35: ...35 NOTES ...

Page 36: ...THANKS FOR REMEMBERING ...