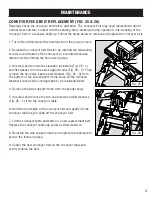

ADJUSTMENTS

WARNING:

To avoid injury from accidental startups, always ensure that the tool is switched

OFF and unplugged from the power supply before making adjustments.

The following settings should be correctly adjusted from the factory. However, they may need to be

checked and adjusted to ensure optimal sanding performance. Refer to the sections below to adjust

the following settings.

• Conveyor belt tension and tracking (page 21)

• Elevation tension screw adjustment (page 22)

• Conveyor belt to drum alignment (page 23)

• Pressure roller adjustment (page 23)

• Elevation stop adjustment (page 24)

CONVEYOR BELT TENSION ADJUSTMENT (FIG. 16)

The conveyor belt tension should be properly adjusted to ensure safe operation and protect the belt

from damage. The belt tension can be adjusted by rotating the tensioning screws on both sides of the

conveyor table. To adjust the belt tension:

1. Turn off and disconnect the machine from the power

source.

2. Release the belt tension equally on both sides of the

table by holding the hex nuts (Fig. 16 - 1) in place while

rotating the tensioning screws (Fig. 16 - 2) counterclockwise.

Position the belt in the center of the rollers.

3. Adjust the tensioning screws so that the end of both

tensioning screws extend about 1/4” beyond the hex nuts

(Fig. 16 - 1).

4. To tighten the belt tension, rotate the tensioning screws

clockwise in small increments until the belt no longer

slips on the rollers. To loosen the belt tension, rotate the

tensioning screws counterclockwise.

1

2

Fig. 16

21

Summary of Contents for 65911

Page 35: ...35 NOTES ...

Page 36: ...THANKS FOR REMEMBERING ...