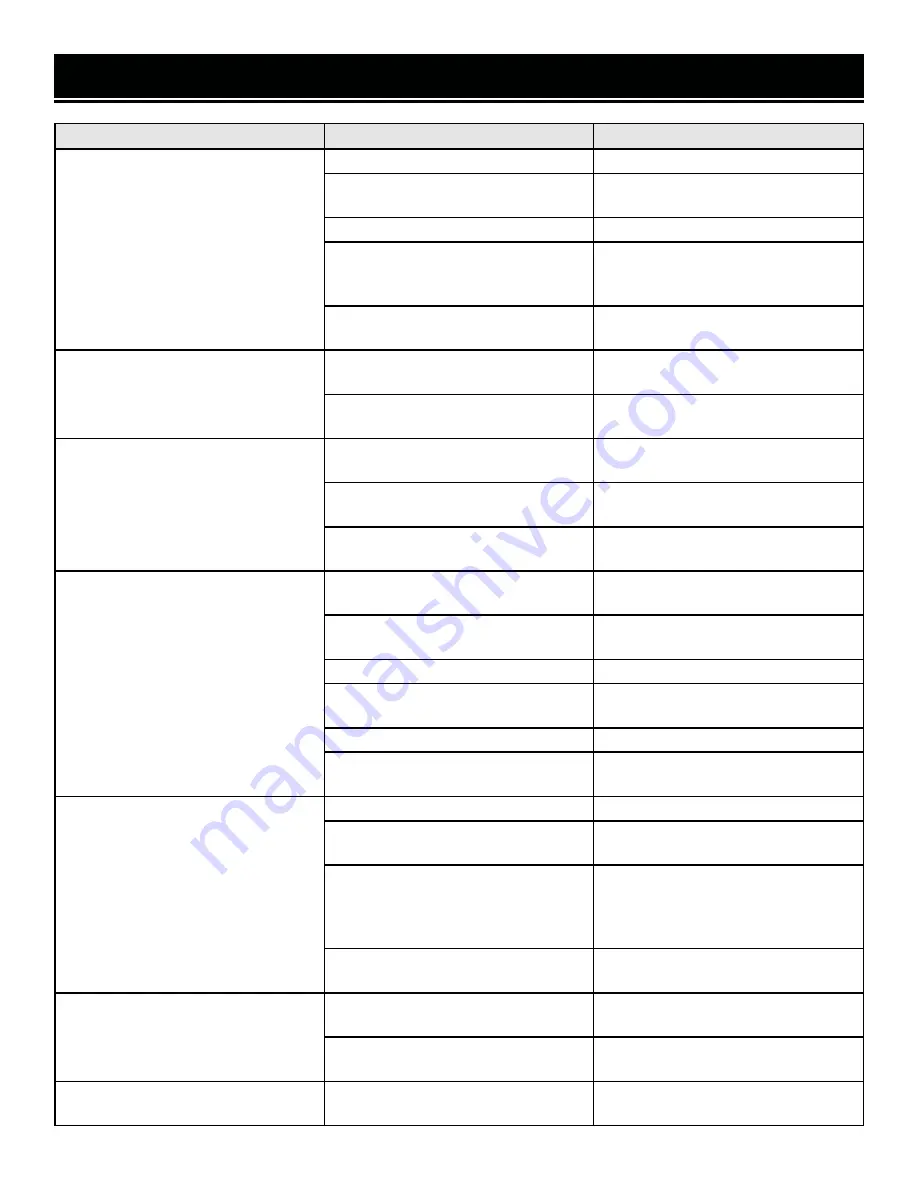

TROUBLESHOOTING GUIDE

PROBLEM

POSSIBLE CAUSE

SOLUTION

Motor will not start.

1. Machine not plugged in.

1. Plug unit into power source.

2. Incorrect size of extension cord.

2. Choose the proper size and length of

extension cord.

3. Worn carbon brushes.

3. Replace carbon brushes; see p. 18.

4. Blown fuse on main PCB.

4. Replace fuse (T5AL250V, 5mm x

20mm). Contact customer service at

1-800-232-1195 for assistance.

5. Defective power switch, PCB, or

motor.

5. Contact customer service at 1-800-

232-1195.

Variable speed does not work.

1. Defective potentiometer (3920B-

075).

1. Contact customer service at 1-800-

232-1195

2. Defective PCB (3920B-049).

2. Contact customer service at 1-800-

232-1195

Dust collection ineffective.

1. Side panel open.

1. Make sure side panel is closed for

optimum dust collection.

2. Dust collection system not strong

enough.

2. Use a stronger system, or reduce the

length of the dust collection hose.

3. Broken/blocked blower bellows or

line.

3. Contact customer service at 1-800-

232-1195.

Excessive vibration.

1. Machine speed set at a harmonic

frequency of the saw.

1. Adjust speed up or down to see if

issue is resolved.

2. Machine not secured to work sur-

face.

2. Secure machine to work surface.

3. Incorrect blade tension.

3. Adjust blade tension (see p. 13).

4. Hold-down foot not being used.

4. Adjust hold-down foot to slightly

clear workpiece surface when cutting.

5. Loose fastener.

5. Check machine for loose fasteners.

6. Defective bearing.

6. Contact customer service at 1-800-

232-1195.

Blades keep breaking.

1. Blade tension set too high.

1. Reduce blade tension; see p. 13.

2. Incorrect blade size.

2. Use a larger (thicker) blade more

suitable for the job at hand.

3. Incorrect blade tooth pitch.

3. Choose a blade with more or fewer

teeth per inch (TPI); a minimum of 3

teeth should contact workpiece at all

times.

4. Excessive pressure on blade.

4. Reduce pressure on blade. Let the

tool do the work.

Blade drift, or otherwise poor cuts.

1. Excessive pressure on blade.

1. Reduce pressure on blade. Let the

tool do the work.

2. Blade mounted upside-down.

2. Mount blade with teeth pointing

down (towards work table).

Tension mechanism does not work.

Broken tension mechanism spring.

Contact customer service at 1-800-

232-1195.

19