ASSEMBLY & ADJUSTMENTS

BLADE SELECTION

This scroll saw accepts 5" long pin-end and pinless blades, with a wide variety of blade thicknesses and widths. The

type of material and intricacies of cutting operations will determine the number of teeth per inch. Always select the

narrowest blades for intricate curve cutting and the widest blades for straight and large curve cutting operations.

The table below represents suggestions for various materials. Use this table as an example, but with practice, per-

sonal preference will be the best selection method.

When choosing a blade, use very fine, narrow blades to scroll cut in thin wood 1/4" thick or less.

Use wider blades for thicker materials

NOTE:

This will reduce the ability to cut tight curves. A smaller blade width can cut circles with smaller diameters.

NOTE:

Thinner blades will tend to deflect more when making bevel cuts.

Teeth per Inch

Blade Width

Blade Thickness

Blade SPM

Material Cut

10 to 15

0.11"

0.018"

500 to 1200 SPM

Medium turns on 1/4" to 1-3/4"

wood, soft metal, hardwood

15 to 28

0.055" to 0.11"

0.01" to 0.018"

800 to 1700 SPM

Small turns on 1/8" to 1-1/2"

wood, soft metal, hardwood

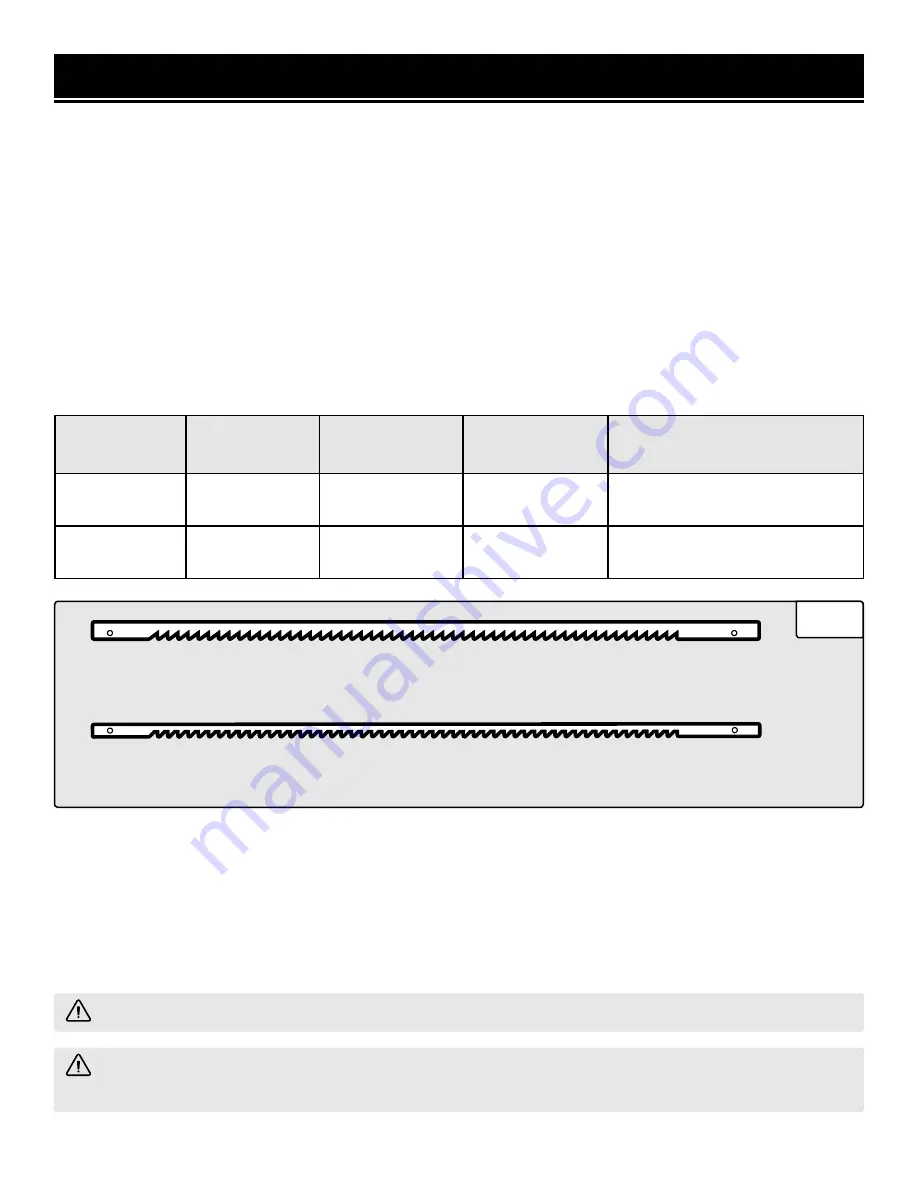

Fig. 10

10 to 15

(Feet per Inch)

15- 28

(Feet per Inch)

BLADE CARE

To maximize the life of your scroll saw blades:

1. Do not bend blades when installing.

2. Always set proper blade tension.

3. Use the right blade (see instruction on replacement blade packaging for proper use).

4. Feed the work correctly into the blade.

5. Use thin blades for intricate cutting.

CAUTION!

Any and all servicing should be performed by a qualified service center.

WARNING!

To prevent personal injury, always turn saw OFF and disconnect the plug from the power source

before changing blades or making adjustments.

12