6

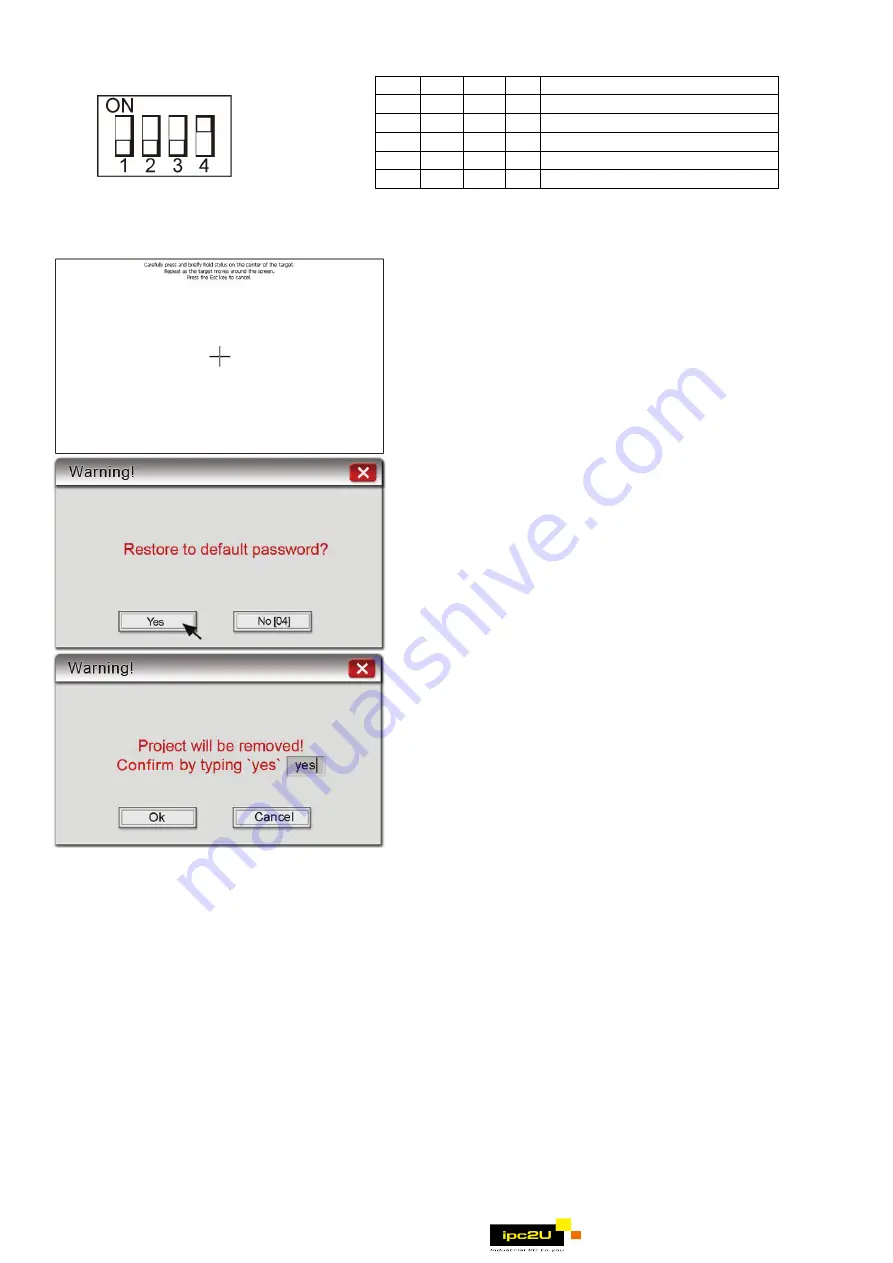

2.3.6 Dip Switch

¼

SW4 is used for adjusting LCD parameters, please keep it in the manufacturer default position, otherwise

incorrect screen display may be occurred.

z

Touch Screen Calibrate and Reset Password mode:

In this mode when you power on the MT8000 series,

the screen will display a “+” sign upper-left of the

screen. Use a stylus or finger to push the center of

the “+” until it moves. The “+” moves to upper-left,

upper-right, lower -left, lower-right and center.

When all five “+” are done the “+” will disappear.

The Touch Screen parameter will be stored in Flash

Rom.

z

If losing or forgetting system passwords, users can

set Dip Switch 1 and 4 to “ON” position, the rest of

Dips remain on “OFF” position and then reboot

MT8000 series. Under this situation, MT8000 series

will jump to Touch Adjust (Touch screen calibration)

mode. After calibration, the pop-up window appears

as the illustration below. Users will be inquired if

restoring the system password to the default value.

z

When “YES” is chosen, another pop-up dialog

appears as below. Users will be confirmed again if

restoring the system password to the default value

and will be asked to input “YES”. Then click OK.

(The default password is 111111. However, other

passwords, including download, upload password

and History backup password, have to be reset.)

Note: When the reset action is taken, projects and saved data

in the HMI will all be cleared.

2.4 Requirements

EU directives that apply to the MT-600/8000 Series:

z

EMC Directive (2004/108/EC) electromagnetic emissions and immunity.

z

UL508

(

ISBN 0-7629-0404-6

)

machine safety for use in Pollution Degree 2 Environment.

z

MT600/8000 products will be CE-marked to indicate compliance with the EMC Directive.

The MT-600/8000 Series has been designed to operate satisfactorily in electromagnetic noise (immunity) and

without emitting high levels of electrical noise into the environment (emission). The units are designed to

meet European Community standards when installed per the wiring instructions in this manual.

Compatibility

Standards

The MT-600/8000 has been designed to meet electromagnetic compatibility for

industrial environments. The CE requirements:

• EN55022:2006+A1:2007, Class A

• EN61000-3-2: 2006

• EN61000-3-3:1995+A1:2001+A2:2005

• EN55024:1998+A1:2001+A2:2003

SW1 SW2 SW3 SW4 Mode

ON

OFF OFF ON Touch Screen Calibrate mode

OFF ON OFF ON Hide MT8000 System Setting Bar

OFF OFF ON ON Boot Loader mode

OFF OFF OFF ON Normal

¼

OFF OFF OFF OFF Not Supported

www.ipc2u.ru