Part number 550-141-402/0801

3

CER Series 2 Electric-Hydronic Boilers Installation Instructions

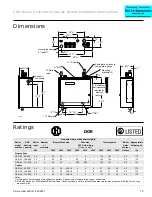

Mounting the boiler

Normally, the boiler will be installed against a frame or

masonry wall. If the wall surface is rough or uneven, it

may be necessary to mount plywood on the wall, then

mount the boiler on the plywood. Refer to

“Dimensions” and “Ratings” on page 13, and note the

boiler weight. Be sure that the wall structure will

support the boiler and its piping.

The

9

/

16

" top mounting holes and

5

/

16

" lower mounting

holes are on 16-inch centers to permit installation on

studs in standard wall construction. The use of ¼" x

2½" lag screws is recommended for mounting the boiler.

The head diameters of the top two screws must not

exceed

9

/

16

".

1.

Locate the top mounting holes so that the boiler

will be level. Install the screws so that the heads

protrude ¾" from the wall.

2.

Raise the boiler to mounting position by placing a

board across the bottom of the boiler or by grasping

the lower left and right inside corners. Do not

attempt to lift the boiler by grasping the bottom

jacket cross tie.

3.

Place the top brackets over the lag screws and then

install screws through the lower mounting holes.

The top screws can now be tightened.

Locating the boiler

The compact construction of the electric-hydronic

boiler permits installation in an alcove, storeroom or

other small area. The location chosen should have

convenient electrical service.

A minimum of 6 inches is required at the top of the

boiler for installation and accessories. A clearance of

18 inches is required on the right hand side for removal

of the elements, and a 2-inch clearance is required

beneath the boiler for ventilation.

General instructions

The Weil-McLain Model CER electric-hydronic boilers

are assembled and tested units designed for use in forced

hot water heating systems. The CER is supplied without

circulator or expansion tank.

Low flow rates through the boiler at elevated

temperatures should be avoided. The structure to be

heated should be insulated in the conventional manner

used in your area for electrically heated buildings. Boiler

must be installed in accordance with these instructions

so as not to void our warranty.

Open the boiler crate and check the contents. In the

event of shortage or damage, notify the transportation

company immediately.

Expansion tank sizing

Undersized expansion tanks cause system water to be

lost from relief valve and makeup water added through

fill valve. Eventual section failure can result.

If a Fill-Trol system is used, refer to Table 1 for proper sizing. If Fill-Trol

action is not desired, size the expansion tank according to the water volume

of the system.

Table 1

Expansion tank sizing (Tank sizing based on 200 °F

average system temperature.)

Hydrostatic pressure test

Pressure test boiler before attaching piping or electrical supply.

1.

Install air vent in tapping on top of boiler.

2.

Plug remaining tappings, including relief valve opening.

3.

Connect water supply. Fill boiler and purge all air. For more than 10

minutes, pressure-test at 1½ times maximum working pressure.

Do not leave boiler unattended. Cold water fill could

expand and cause excess pressure, resulting in severe

personal injury, death or substantial property damage.

4.

Check for maintained gauge pressure. Visually check for leaks if gauge

pressure drops.

5.

Drain boiler and repair leaks if found.

Leaks must be repaired at once. Failure to do so can

damage boiler, resulting in substantial property damage.

6.

Retest boiler after repairing leaks.

7.

Remove testing plugs and air vent.

Do not use petroleum-based cleaning or sealing

compounds in boiler system. Severe damage to boiler

will result, causing substantial property damage.

Pre-installation

Boiler

model

number

Standard Fill-Trol tank

(for series loop or one-pipe system

with convector baseboard)

Additional Fill-Trol tank

(for cast-iron radiators or

cast-iron baseboard)

CER-24

No. 109

No. 110

CER-32

No. 109

No. 110

CER-40

No. 109

No. 110

Note: Gravity systems converted to a forced hot water system usually require

additional compression tank capacity.