Troubleshooting

5658600000/00/05.07

23

6.

Troubleshooting

This chapter is about troubleshooting if the following

problems with the printer occur:

6.1 Fuses

A

B

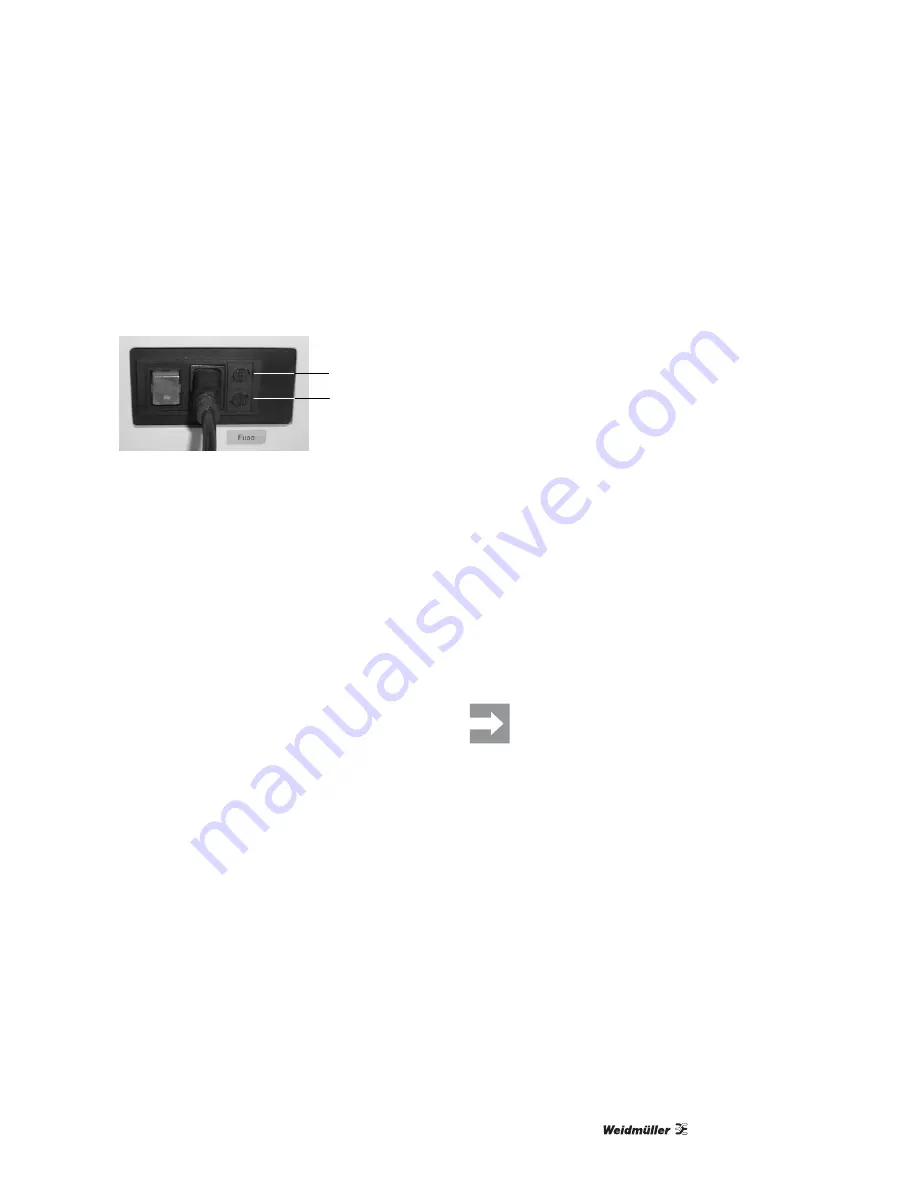

Figure 19

Fuses

A

Upper fuse:

5 x 20 mm 10 A / Slow

→

Control printer

B

Lower fuse:

5 x 20 mm 10 A / Slow

→

Power circuit of the

pre-heating and of the fixation unit

The lower fuse is for the power circuit of the pre-

heating and for the fixation unit. If this fuse fails, nei-

ther of the heaters will work.

The upper fuse is for the control of the printer. If the

control is not working, the printer cannot be switched

on.

This device is subject to special conditions regarding

its connection to the mains supply (EU Member

States).

The supply impedance at the point of connection to

the public electricity supply must not exceed (0.14 +

i 0.09) Ohm.

In all other cases, consult the power supply com-

pany before connecting the device to the public sup-

ply system.

6.2 Overheating

shutoff

During long operation, the device may be shutoff to

save it from overheating.

The error LED is lit. If pressing the button

Test

does

not lead to an intake of a MultiCard, leave the device

on for 10 - 15 minutes for cooling down and press

the button

Test

again. The stored printing jobs will

be processed.

6.3 Remedy

for

jamming

Occasionally, jamming of MultiCards can occur dur-

ing a printout.

Jamming can occur in the following areas:

•

Input area

•

Toner cartridge area

•

Output area

Normally, jamming occurs in the following cases:

•

A MultiCard strip has not been loaded or trans-

ported properly.

•

The cover was opened during printing.

•

In the input area was a deficient or an incomplete

MultiCard strip.

Remove the accumulated MultiCard and

follow the instructions on the following

pages. If it is not clear where the problem

was, look at first in the area of the toner

cartridge.

Summary of Contents for SpeedMarking-Laser

Page 1: ...SpeedMarking Laser User s Manual...

Page 2: ......

Page 32: ...Printer specifications 32 5658600000 00 05 07...

Page 34: ......

Page 35: ......