Page 19

General Maintenance and Care

SG Manual

H. GENERAL MAINTENANCE AND CARE (continued)

As a minimum, the following replacement parts should be

stocked to support uninterrupted burner operation.

Electrode

Blower Wheel

Ignition Transformer

Gas Solenoid Valve

Flame Scanner

Items with greater life expectancy and/or greater dollar

value, such as flame safety controls, main gas valves and

blower motors should be obtained from your local Webster

representative when a need arises.

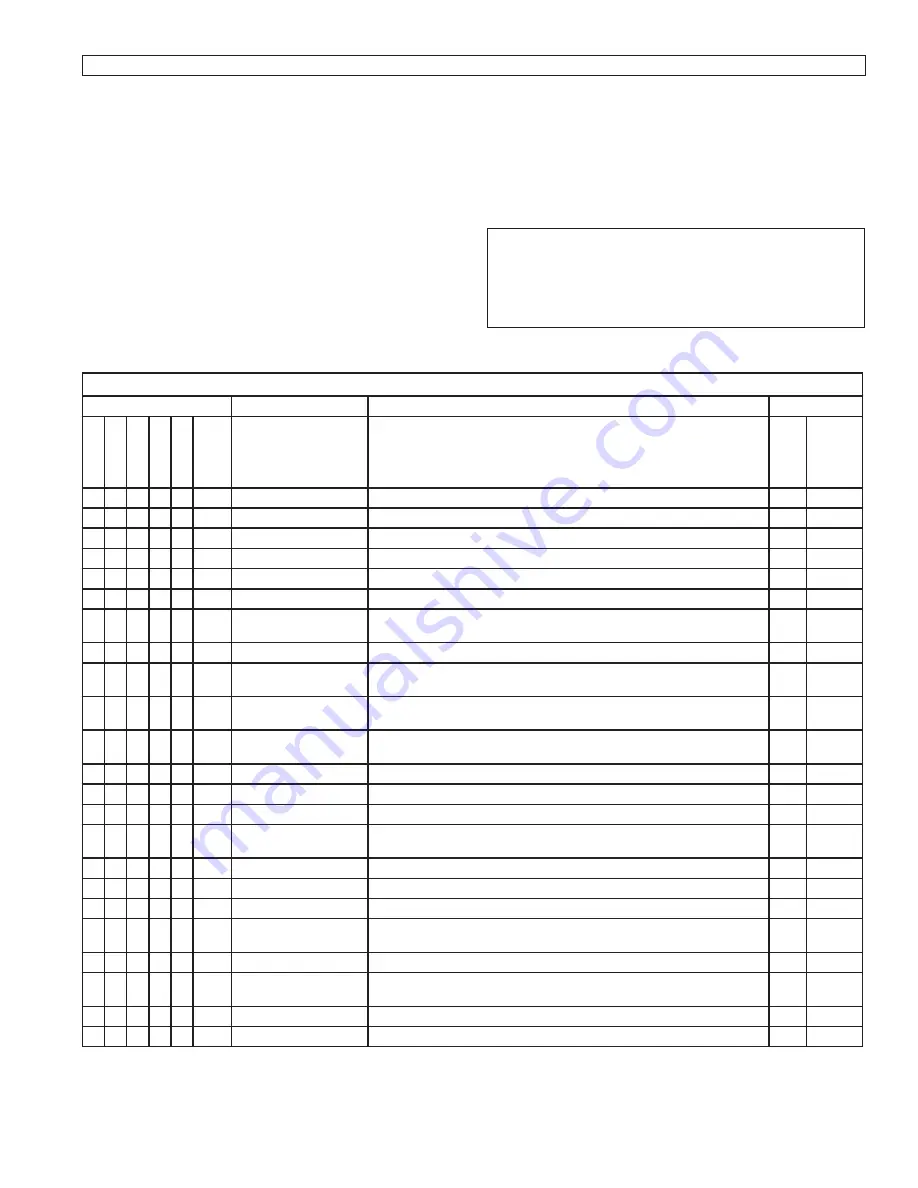

8 - Inspection and Maintenance Schedule

Frequency

Performed By

Daily

W

eekly

Monthly

Seasonal

Annual

Annual

As

Required

Component / Item

Recommended Action or Test

Boiler

Operator

Trained Burner

Technician

X

Burner Flame

Visual inspection of burner flame.

X

X

Jackshaft and Linkage

Visual inspection for smooth and free travel.

X

X

Air Damper

Visual inspection for smooth and free travel.

X

X

Fuel Metering Valves

Visual inspection for smooth and free travel.

X

X

Draft Controls (Stack)

Visual inspection for smooth and free travel.

X

X

Gas Fuel Pressure

Record in log book, compare trends.

X

X

Flame SafeGuard - Main

Flame

Close manual fuel valve on pilot during cycle and check for safety shutdown,

recording time.

X

X

Flame SafeGuard

Check flame safeguard components, including scanner.

X

X

Flame SafeGuard

Replace flame safeguard components in accordance with manufacturers

instructions.

X

X

X

Hot Refractory Test

Conduct hot refractory hold in test. This test is required annually or after any

component change.

X

X

Interlock Controls

Check other interlocks that may be used on the burner for smooth operation

and correct action.

X

X

Firing Rate Control

Check firing rate control and verify settings.

X

X

Combustion Tuning

Conduct a combustion test, verify setting and NOx emission levels.

X

X

Main Fuel Valves

Make visual and manual check for proper sequencing of valves.

X

X

Main Fuel Valves

Check all coils, diaphragms, interlock switch & other parts of all safety shutoff

valves.

X

X

Main Fuel Valves

Perform leak tests on all safety shutdown control valves.

X

X

Low Pressure Air Switch

Test low air pressure switch for proper operation and adjustment.

X

X

Mod Damper Switch

Check damper low fire proving switch per manufacturers instructions.

X

X

Linkage and Fuel Cams

Check linkage and cams for wear and replace any items with wear indication

or stress cracks.

X

X

Combustion Air Fan

Clean combustion air fan and housing

X

X X

Burner Components

Visually check the burner components for signs of cracks, deformation, slip-

page or other unusual indication.

X

X

Burner Mounting

Check burner mounting clamps and brackets for tightness.

X

X

Refractory and Seals

Check burner refractory for cracks or signs of leakage.

X

NOTE

Always give Webster Engineering Serial

Number and/or UL Serial Number when

ordering parts.

An illustrated parts drawing is included within the Burner

Instructions Manual to aid in parts identification. The noun

name of the part needed should be established from the

drawing, then the part number can be obtained from the

burner material list contained in the Burner Instructions

and Service Manual.

Summary of Contents for Cyclonetic SG Series

Page 22: ...Page 22 SG Manual Notes NOTES ...

Page 23: ...Page 23 SG Manual Notes NOTES ...