PWSR Series Softeners

13

Control Programming

General Operation

User (U) Displays/Settings

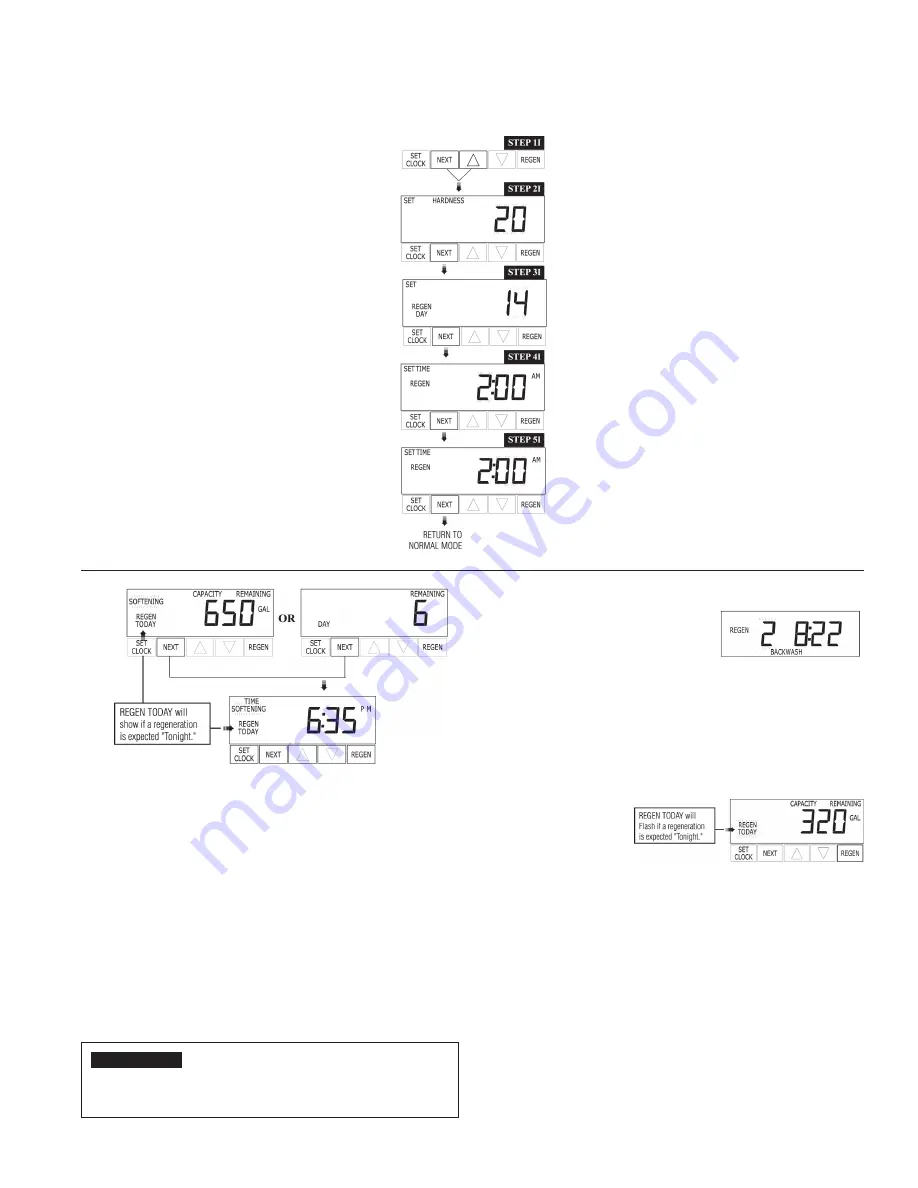

When the system is operating one of two displays will be

shown. Pressing NEXT will alternate between the displays.

One of the displays is always the current time of day. The

second display is one of the following: days remaining or

gallons remaining. Days remaining are the number of days

left before the system goes through a regeneration cycle.

Capacity remaining is the number of gallons that will be treat-

ed before the system goes through a regeneration cycle. The

user can scroll between the displays as desired.

If the system has called for a regeneration that will occur at

the preset time of regeneration, the words REGEN TODAY

will appear on the display.

When water is being treated (i.e. water is flowing through the

system) the word “Softening” flashes on the display.

REGENERATION MODE

Typically a system is set to regener-

ate at a time of low water usage. An

example of a time with low water

usage is when a household is asleep.

If there is a demand for water when the system is regenerating,

untreated water will be used.

When the system begins to regenerate, the display will change

to include information about the step of the regeneration process

and the time remaining for that step to be completed. The system

runs through the steps automatically and will reset itself to pro-

vide treated water when the regeneration has been completed.

MANUAL

REGENERATION

Sometimes there is a

need to regenerate

the system, sooner

than when the system calls for it, usually referred to as manual

regeneration. There may be a period of heavy water usage

because of guests or a heavy laundry day.

To initiate a manual regeneration at the preset delayed regener-

ation time, when the regeneration time option is set to “NORMAL”

or “ on 0”, press and release “REGEN”. The words

“REGEN TODAY” will flash on the display to indicate that the sys-

tem will regenerate at the preset delayed regeneration time. If

you pressed the “REGEN” button in error, pressing the button

again will cancel the request. Note: If the regeneration time

option is set to “on 0” there is no set delayed regeneration time

so “REGEN TODAY” will not activate if “REGEN” button is

pressed.

To initiate a manual regeneration immediately, press and hold the

“REGEN” button for three seconds. The system will begin to

regenerate immediately. The request cannot be cancelled.

11

CONTROL PROGRAMMING

INSTALLER (

I

) Displays/Settings

STEP 1

I

– Press NEXT and arrow up simulta-

neously for 3 seconds.

STEP 2

I

– Hardness: Set the amount of hard-

ness in grains of hardness as calcium carbonate

per gallon using, arrow down or arrow up but-

tons. The default is 20 with value ranges from 1

to 150 in 1 grain increments. Note the grains per

gallon can be increased if soluble iron needs to

be reduced. Press NEXT to go to step 3I. Press

REGEN to exit Installer Displays/Settings.

STEP 3

I

– Day Override: When gallon capacity

is set to off, sets the number of days between

regeneration’s. When gallon capacity is set to

AUTO or to a number sets the maximum number

of days between regeneration. If value set to “off”

regeneration initiation is based solely on gallons

used. If value is set as a number (allowable

range from 1 to 28) a regeneration initiation

will be called for on that day even if sufficient

number of gallons were not used to call for

a regeneration. Set Day Override using arrow

buttons: number to days between regeneration

(1 to 28); or OFF.

Press NEXT to go to step 4

I

. Press REGEN to

return to previous step.

STEP 4

I

– Next Regeneration Time (hour): Set

the hour of day for regeneration using down or up

arrow buttons. AM/PM toggles after 12. The

default time is 2:00 am. This display shows

“REGEN on 0 GAL” if “on 0” is selected in Step

9S or Step 7F. Press NEXT to go to step 5

I

.

Press REGEN to return to previous step.

STEP 5

I

– Next Regeneration Time (minutes):

Set the minutes of day regeneration using down

or up arrow buttons. This display not be shown if

“on 0” is selected in Step 9S or Step 7F. Press

NEXT to exit Installer Displays/ Settings. Press

REGEN to return to previous step.

To initiate a manual regeneration immediately,

press and hold the “REGEN” button for three

seconds. The system will beam to regenerate

immediately. The control valve may be stepped

through the various regeneration cycles by

pressing the “REGEN” button.

Note: If brine tank does not contain salt, fill with salt

and wait at least two hours before regenerating.

Installer (I) Displays/Settings

STEP 1I –

Press NEXT and arrow up simultaneously

for 3 seconds .

STEP 2I –

Hardness: Set the amount of hardness

in grains of hardness as calcium carbonate per

gallon using, arrow down or arrow up but-tons . The

default is 20 with value ranges from 1 to 150 in 1

grain increments . Note the grains per gallon can be

increased if soluble iron needs to be reduced . Press

NEXT to go to step 3I . Press REGEN to exit Installer

Displays/Settings .

STEP 3I –

Day Override: When gallon capacity

is set to off, sets the number of days between

regeneration’s . When gallon capacity is set to AUTO

or to a number sets the maximum number of days

between regeneration . If value set to “off” regeneration

initiation is based solely on gallons used . If value is

set as a number (allowable range from 1 to 28) a

regeneration initiation will be called for on that day

even if sufficient number of gallons were not used to

call for a regeneration . Set Day Override using arrow

buttons: number to days between regeneration (1 to

28); or OFF .

Press NEXT to go to step 4I . Press REGEN to return

to previous step .

STEP 4I –

Next Regeneration Time (hour): Set the

hour of day for regeneration using down or up arrow

buttons . AM/PM toggles after 12 . The default time is

2:00 am . This display shows “REGEN on 0 GAL” if “on

0” is selected in Step 9S or Step 7F . Press NEXT to go

to step 5I . Press REGEN to return to previous step .

STEP 5I –

Next Regeneration Time (minutes): Set the

minutes of day regeneration using down or up arrow

buttons . This display not be shown if “on 0” is selected

in Step 9S or Step 7F . Press NEXT to exit Installer

Displays/ Settings . Press REGEN to return to previous

step .

To initiate a manual regeneration immediately, press

and hold the “REGEN” button for three seconds .

The system will beam to regenerate immediately . The

control valve may be stepped through the various

regeneration cycles by pressing the “REGEN” button .

General Operation

User (U) Displays/Settings

When the system is operating one of two displays will be

shown. Pressing NEXT will alternate between the displays.

One of the displays is always the current time of day. The

second display is one of the following: days remaining or

gallons remaining. Days remaining are the number of days

left before the system goes through a regeneration cycle.

Capacity remaining is the number of gallons that will be treat-

ed before the system goes through a regeneration cycle. The

user can scroll between the displays as desired.

If the system has called for a regeneration that will occur at

the preset time of regeneration, the words REGEN TODAY

will appear on the display.

When water is being treated (i.e. water is flowing through the

system) the word “Softening” flashes on the display.

REGENERATION MODE

Typically a system is set to regener-

ate at a time of low water usage. An

example of a time with low water

usage is when a household is asleep.

If there is a demand for water when the system is regenerating,

untreated water will be used.

When the system begins to regenerate, the display will change

to include information about the step of the regeneration process

and the time remaining for that step to be completed. The system

runs through the steps automatically and will reset itself to pro-

vide treated water when the regeneration has been completed.

MANUAL

REGENERATION

Sometimes there is a

need to regenerate

the system, sooner

than when the system calls for it, usually referred to as manual

regeneration. There may be a period of heavy water usage

because of guests or a heavy laundry day.

To initiate a manual regeneration at the preset delayed regener-

ation time, when the regeneration time option is set to “NORMAL”

or “ on 0”, press and release “REGEN”. The words

“REGEN TODAY” will flash on the display to indicate that the sys-

tem will regenerate at the preset delayed regeneration time. If

you pressed the “REGEN” button in error, pressing the button

again will cancel the request. Note: If the regeneration time

option is set to “on 0” there is no set delayed regeneration time

so “REGEN TODAY” will not activate if “REGEN” button is

pressed.

To initiate a manual regeneration immediately, press and hold the

“REGEN” button for three seconds. The system will begin to

regenerate immediately. The request cannot be cancelled.

11

CONTROL PROGRAMMING

INSTALLER (

I

) Displays/Settings

STEP 1

I

– Press NEXT and arrow up simulta-

neously for 3 seconds.

STEP 2

I

– Hardness: Set the amount of hard-

ness in grains of hardness as calcium carbonate

per gallon using, arrow down or arrow up but-

tons. The default is 20 with value ranges from 1

to 150 in 1 grain increments. Note the grains per

gallon can be increased if soluble iron needs to

be reduced. Press NEXT to go to step 3I. Press

REGEN to exit Installer Displays/Settings.

STEP 3

I

– Day Override: When gallon capacity

is set to off, sets the number of days between

regeneration’s. When gallon capacity is set to

AUTO or to a number sets the maximum number

of days between regeneration. If value set to “off”

regeneration initiation is based solely on gallons

used. If value is set as a number (allowable

range from 1 to 28) a regeneration initiation

will be called for on that day even if sufficient

number of gallons were not used to call for

a regeneration. Set Day Override using arrow

buttons: number to days between regeneration

(1 to 28); or OFF.

Press NEXT to go to step 4

I

. Press REGEN to

return to previous step.

STEP 4

I

– Next Regeneration Time (hour): Set

the hour of day for regeneration using down or up

arrow buttons. AM/PM toggles after 12. The

default time is 2:00 am. This display shows

“REGEN on 0 GAL” if “on 0” is selected in Step

9S or Step 7F. Press NEXT to go to step 5

I

.

Press REGEN to return to previous step.

STEP 5

I

– Next Regeneration Time (minutes):

Set the minutes of day regeneration using down

or up arrow buttons. This display not be shown if

“on 0” is selected in Step 9S or Step 7F. Press

NEXT to exit Installer Displays/ Settings. Press

REGEN to return to previous step.

To initiate a manual regeneration immediately,

press and hold the “REGEN” button for three

seconds. The system will beam to regenerate

immediately. The control valve may be stepped

through the various regeneration cycles by

pressing the “REGEN” button.

Note: If brine tank does not contain salt, fill with salt

and wait at least two hours before regenerating.

General Operation

User (U) Displays/Settings

When the system is operating one of two displays will be shown .

Pressing NEXT will alternate between the displays . One of the

displays is always the current time of day . The second display is one

of the following: days remaining or gallons remaining . Days remaining

are the number of days left before the system goes through a

regeneration cycle . Capacity remaining is the number of gallons that

will be treated before the system goes through a regeneration cycle .

The user can scroll between the displays as desired .

If the system has called for a regeneration that will occur at the

preset time of regeneration, the words REGEN TODAY will appear on

the display .

When water is being treated (i .e . water is flowing through the system)

the word “Softening” flashes on the display .

NOTICE

If brine tank does not contain salt, fill with salt and wait at least

two hours before regenerating .

Regeneration Mode

Typically a system is set to regenerate at

a time of low water usage . An example

of a time with low water usage is when a

household is asleep .

If there is a demand for water when the system is regenerating,

untreated water will be used .

When the system begins to regenerate, the display will change

to include information about the step of the regeneration process

and the time remaining for that step to be completed . The system

runs through the steps automatically and will reset itself to pro-vide

treated water when the regeneration has been completed .

Manual

Regeneration

Sometimes there is a

need to regenerate the

system, sooner than when

the system calls for it, usually referred to as manual regeneration .

There may be a period of heavy water usage because of guests or a

heavy laundry day .

To initiate a manual regeneration at the preset delayed regeneration

time, when the regeneration time option is set to “NORMAL” or

“ on 0”, press and release “REGEN” . The words “REGEN

TODAY” will flash on the display to indicate that the system will

regenerate at the preset delayed regeneration time . If you pressed

the “REGEN” button in error, pressing the button again will cancel

the request . Note: If the regeneration time option is set to “on 0”

there is no set delayed regeneration time so “REGEN TODAY” will

not activate if “REGEN” button is pressed .

To initiate a manual regeneration immediately, press and hold

the “REGEN” button for three seconds . The system will begin to

regenerate immediately . The request cannot be cancelled .

General Operation

User (U) Displays/Settings

When the system is operating one of two displays will be

shown. Pressing NEXT will alternate between the displays.

One of the displays is always the current time of day. The

second display is one of the following: days remaining or

gallons remaining. Days remaining are the number of days

left before the system goes through a regeneration cycle.

Capacity remaining is the number of gallons that will be treat-

ed before the system goes through a regeneration cycle. The

user can scroll between the displays as desired.

If the system has called for a regeneration that will occur at

the preset time of regeneration, the words REGEN TODAY

will appear on the display.

When water is being treated (i.e. water is flowing through the

system) the word “Softening” flashes on the display.

REGENERATION MODE

Typically a system is set to regener-

ate at a time of low water usage. An

example of a time with low water

usage is when a household is asleep.

If there is a demand for water when the system is regenerating,

untreated water will be used.

When the system begins to regenerate, the display will change

to include information about the step of the regeneration process

and the time remaining for that step to be completed. The system

runs through the steps automatically and will reset itself to pro-

vide treated water when the regeneration has been completed.

MANUAL

REGENERATION

Sometimes there is a

need to regenerate

the system, sooner

than when the system calls for it, usually referred to as manual

regeneration. There may be a period of heavy water usage

because of guests or a heavy laundry day.

To initiate a manual regeneration at the preset delayed regener-

ation time, when the regeneration time option is set to “NORMAL”

or “ on 0”, press and release “REGEN”. The words

“REGEN TODAY” will flash on the display to indicate that the sys-

tem will regenerate at the preset delayed regeneration time. If

you pressed the “REGEN” button in error, pressing the button

again will cancel the request. Note: If the regeneration time

option is set to “on 0” there is no set delayed regeneration time

so “REGEN TODAY” will not activate if “REGEN” button is

pressed.

To initiate a manual regeneration immediately, press and hold the

“REGEN” button for three seconds. The system will begin to

regenerate immediately. The request cannot be cancelled.

11

CONTROL PROGRAMMING

INSTALLER (

I

) Displays/Settings

STEP 1

I

– Press NEXT and arrow up simulta-

neously for 3 seconds.

STEP 2

I

– Hardness: Set the amount of hard-

ness in grains of hardness as calcium carbonate

per gallon using, arrow down or arrow up but-

tons. The default is 20 with value ranges from 1

to 150 in 1 grain increments. Note the grains per

gallon can be increased if soluble iron needs to

be reduced. Press NEXT to go to step 3I. Press

REGEN to exit Installer Displays/Settings.

STEP 3

I

– Day Override: When gallon capacity

is set to off, sets the number of days between

regeneration’s. When gallon capacity is set to

AUTO or to a number sets the maximum number

of days between regeneration. If value set to “off”

regeneration initiation is based solely on gallons

used. If value is set as a number (allowable

range from 1 to 28) a regeneration initiation

will be called for on that day even if sufficient

number of gallons were not used to call for

a regeneration. Set Day Override using arrow

buttons: number to days between regeneration

(1 to 28); or OFF.

Press NEXT to go to step 4

I

. Press REGEN to

return to previous step.

STEP 4

I

– Next Regeneration Time (hour): Set

the hour of day for regeneration using down or up

arrow buttons. AM/PM toggles after 12. The

default time is 2:00 am. This display shows

“REGEN on 0 GAL” if “on 0” is selected in Step

9S or Step 7F. Press NEXT to go to step 5

I

.

Press REGEN to return to previous step.

STEP 5

I

– Next Regeneration Time (minutes):

Set the minutes of day regeneration using down

or up arrow buttons. This display not be shown if

“on 0” is selected in Step 9S or Step 7F. Press

NEXT to exit Installer Displays/ Settings. Press

REGEN to return to previous step.

To initiate a manual regeneration immediately,

press and hold the “REGEN” button for three

seconds. The system will beam to regenerate

immediately. The control valve may be stepped

through the various regeneration cycles by

pressing the “REGEN” button.

Note: If brine tank does not contain salt, fill with salt

and wait at least two hours before regenerating.

General Operation

User (U) Displays/Settings

When the system is operating one of two displays will be

shown. Pressing NEXT will alternate between the displays.

One of the displays is always the current time of day. The

second display is one of the following: days remaining or

gallons remaining. Days remaining are the number of days

left before the system goes through a regeneration cycle.

Capacity remaining is the number of gallons that will be treat-

ed before the system goes through a regeneration cycle. The

user can scroll between the displays as desired.

If the system has called for a regeneration that will occur at

the preset time of regeneration, the words REGEN TODAY

will appear on the display.

When water is being treated (i.e. water is flowing through the

system) the word “Softening” flashes on the display.

REGENERATION MODE

Typically a system is set to regener-

ate at a time of low water usage. An

example of a time with low water

usage is when a household is asleep.

If there is a demand for water when the system is regenerating,

untreated water will be used.

When the system begins to regenerate, the display will change

to include information about the step of the regeneration process

and the time remaining for that step to be completed. The system

runs through the steps automatically and will reset itself to pro-

vide treated water when the regeneration has been completed.

MANUAL

REGENERATION

Sometimes there is a

need to regenerate

the system, sooner

than when the system calls for it, usually referred to as manual

regeneration. There may be a period of heavy water usage

because of guests or a heavy laundry day.

To initiate a manual regeneration at the preset delayed regener-

ation time, when the regeneration time option is set to “NORMAL”

or “ on 0”, press and release “REGEN”. The words

“REGEN TODAY” will flash on the display to indicate that the sys-

tem will regenerate at the preset delayed regeneration time. If

you pressed the “REGEN” button in error, pressing the button

again will cancel the request. Note: If the regeneration time

option is set to “on 0” there is no set delayed regeneration time

so “REGEN TODAY” will not activate if “REGEN” button is

pressed.

To initiate a manual regeneration immediately, press and hold the

“REGEN” button for three seconds. The system will begin to

regenerate immediately. The request cannot be cancelled.

11

CONTROL PROGRAMMING

INSTALLER (

I

) Displays/Settings

STEP 1

I

– Press NEXT and arrow up simulta-

neously for 3 seconds.

STEP 2

I

– Hardness: Set the amount of hard-

ness in grains of hardness as calcium carbonate

per gallon using, arrow down or arrow up but-

tons. The default is 20 with value ranges from 1

to 150 in 1 grain increments. Note the grains per

gallon can be increased if soluble iron needs to

be reduced. Press NEXT to go to step 3I. Press

REGEN to exit Installer Displays/Settings.

STEP 3

I

– Day Override: When gallon capacity

is set to off, sets the number of days between

regeneration’s. When gallon capacity is set to

AUTO or to a number sets the maximum number

of days between regeneration. If value set to “off”

regeneration initiation is based solely on gallons

used. If value is set as a number (allowable

range from 1 to 28) a regeneration initiation

will be called for on that day even if sufficient

number of gallons were not used to call for

a regeneration. Set Day Override using arrow

buttons: number to days between regeneration

(1 to 28); or OFF.

Press NEXT to go to step 4

I

. Press REGEN to

return to previous step.

STEP 4

I

– Next Regeneration Time (hour): Set

the hour of day for regeneration using down or up

arrow buttons. AM/PM toggles after 12. The

default time is 2:00 am. This display shows

“REGEN on 0 GAL” if “on 0” is selected in Step

9S or Step 7F. Press NEXT to go to step 5

I

.

Press REGEN to return to previous step.

STEP 5

I

– Next Regeneration Time (minutes):

Set the minutes of day regeneration using down

or up arrow buttons. This display not be shown if

“on 0” is selected in Step 9S or Step 7F. Press

NEXT to exit Installer Displays/ Settings. Press

REGEN to return to previous step.

To initiate a manual regeneration immediately,

press and hold the “REGEN” button for three

seconds. The system will beam to regenerate

immediately. The control valve may be stepped

through the various regeneration cycles by

pressing the “REGEN” button.

Note: If brine tank does not contain salt, fill with salt

and wait at least two hours before regenerating.

Summary of Contents for PWSR Series

Page 27: ...NOTES ...