User Guide & Instruction Manual

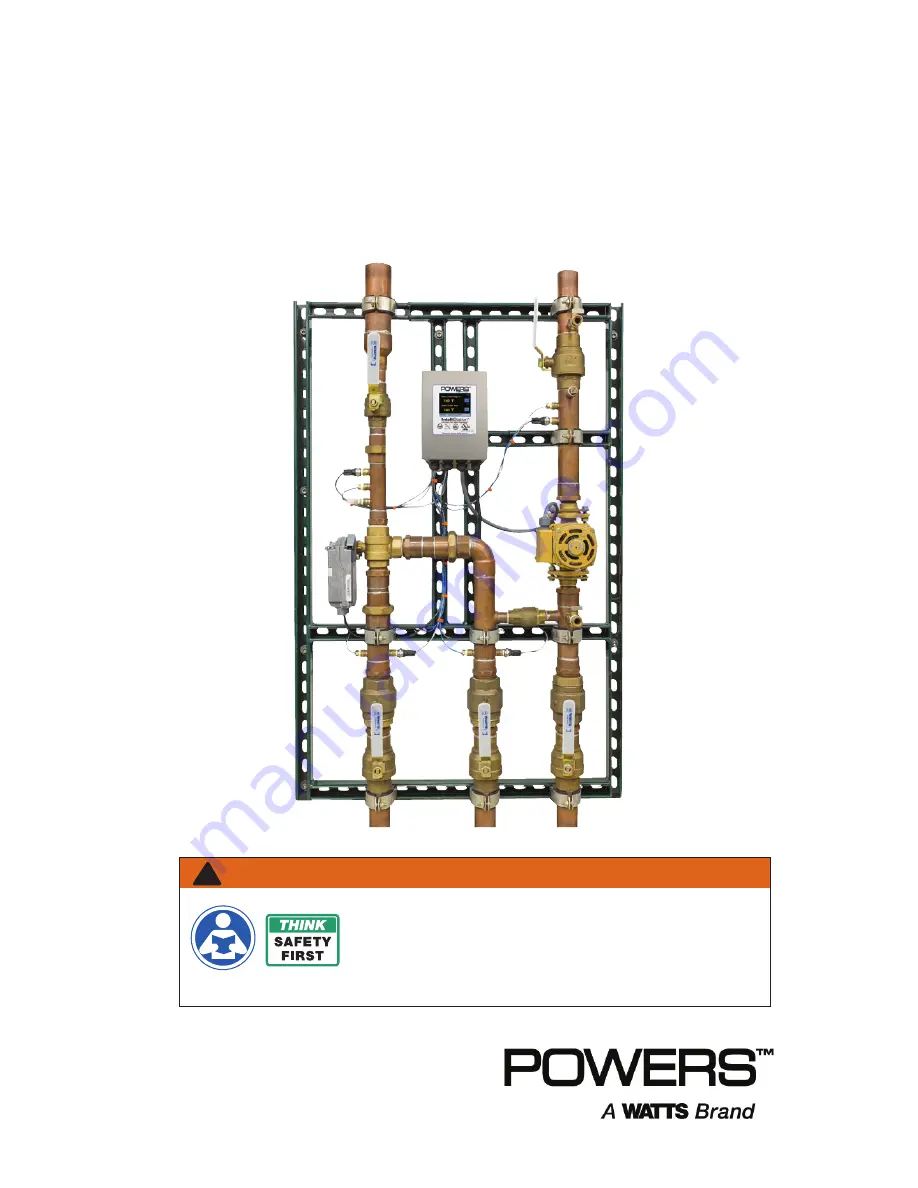

Intelli

Station

®

Digital Water Mixing

and Recirculation System

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use information can result

in death, serious personal injury, property damage, or damage to the

equipment. Visit PowersControls.com with any questions.

Keep this Manual for future reference.

WARNING

!

Summary of Contents for Powers IntelliStation

Page 2: ......