7

4.2 Plumbing and Air Connections

To avoid injury, death, fire, explosion, leak, or property damage:

• The fluid waste from the drain connection MUST NEVER

BE reintroduced into the incoming water stream. HF

scientific recommends that operators review with local

authorities concerning the proper disposal of waste

diluted fluids.

• All plumbing connections MUST BE made through the

provided stainless steel connections. Fittings should not

be modified or substituted.

• The air line and the water line MUST NOT BE reversed

in connecting the supplies. Connecting the water source

to the air line will damage the electronics and void

the warranty.

• All connections MUST BE properly installed and sealed

to ensure water tightness and preserve the ratings of

the instrument.

• The drain MUST BE open to the atmosphere for proper

operation. Ensure the vent drain remains open and is not

subject to fouling.

All wet and air connections are made with user supplied tubing using

the compression fittings attached to the SSR-Ex. When using the

compression fittings, follow these steps:

Step 1: Unscrew the nut from the applicable connection point.

Step 2: Remove the nut, front sleeve, and back sleeve from the

SSR-Ex.

Step 3: Place the nut, then the back sleeve, and then the front sleeve

onto the applicable tubing.

Step 4: Slide the tubing into the open connection point and

tighten the nut to secure the tubing. Refer to Figure 9.

Fitting Connections for assistance to assemble the tubing

connection. Refer to Figure 10 - Utility Connections for

assistance locating the proper fitting connection on the

enclosure for the sample to be connected.

Figure 9 - Compression Fitting

When making the plumbing connections, be advised that:

• The maximum pressure for proper operation is 3 bar (45 PSI).

• The maximum sample water intake and drainage flow is

150 ml/minute.

• The maximum allowable fluid temperature is 55°C (131°F).

• The sample water supply does not need to be pressurized.

The SSR-Ex incorporates a pressure regulator at the water

supply inlet.

• In order to ensure that the sample measured is representative of

the ballast water, keep sample pipe runs as short as possible.

• A water shut off valve should be located close to the instrument

to allow for periodic maintenance.

• An air shut off valve should be located close to the instrument to

allow for periodic maintenance.

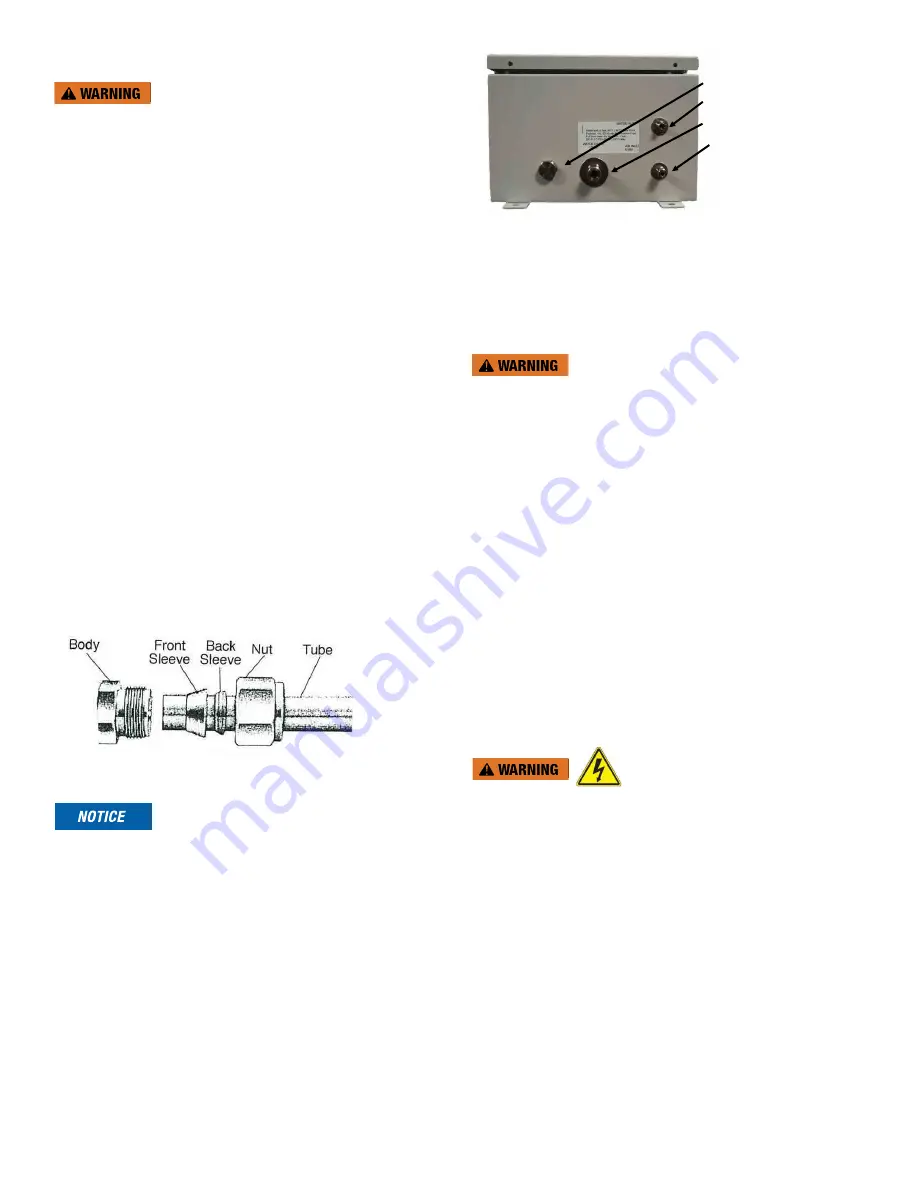

EMERGENCY DRAIN (NO CONNECTION

NEEDED)

SAMPLE WATER (6mm connection)

MAIN DRAIN (12 mm connection)

PURGE AIR (AIR ONLY 6mm

connection)

NOTE: IMAGE DEPICTS BOTTOM OF

THE ENCLOSURE.

DO NOT MIX UP THE AIR and WATER

CONNECTIONS. INSTALLING THE

WATER INTO THE AIR CONNECTION

WILL VOID THE WARRANTY.

Figure 10 - Utility Connections

All wet and air connections are made with user supplied OD tubing

using the compression fittings attached to the SSR-Ex. All air and water

tubing connected to the instrument is to be supplied by others. When

using the compression fittings, see Figure 9 - Compression Fitting and

then follow these steps:

Do not connect sample water line to the purge air connection.

Plumbing Connections

Step 1: Connect the sample water line to the SSR-Ex using the 6 mm

OD fitting on the bottom of the enclosure. Reference Figure

10 - Utility Connections.

Step 2: Connect the main drain line to the SSR-Ex using the 12 mm

OD fitting on the bottom of the enclosure.

Reference Figure 10 - Utility Connections. There is no tubing

connection for the emergency drain.

Air Connection

Step 1: Install the air/filter dryer assembly by mounting it in

a convenient location near the SSR-Ex between the

compressed air supply and the SSR-Ex.

Step 2: Connect the compressed air supply to the air/filter dryer

assembly intake.

Step 3: Connect the air supply tubing from the air/filter dryer

assembly output to the SSR-Ex using the 6 mm OD fitting

on the bottom of the enclosure. Reference Figure 10 - Utility

Connections.

4.3 Electrical Connections

The power must be provided by a safe remote location. All

power must be removed from a safe location while the electrical

compartment access is open. Do not reconnect power until the

electrical compartment access is closed and all captive Philips

screws have been replaced and tightened appropriately.

All electrical connections are located in the upper electrical

compartment. The electrical compartment access at the front

can and should only be opened during installation. No power

should be applied until the electrical compartment access is

closed and sealed.

The SSR-Ex has two types of electrical connections. First, the mains

power connection, which connects to the Air Sentinel II through the

cable gland on the left side of the SSR-Ex. Second, the low voltage

connections, which are made through the cable glands on the right

side of the SSR-Ex.