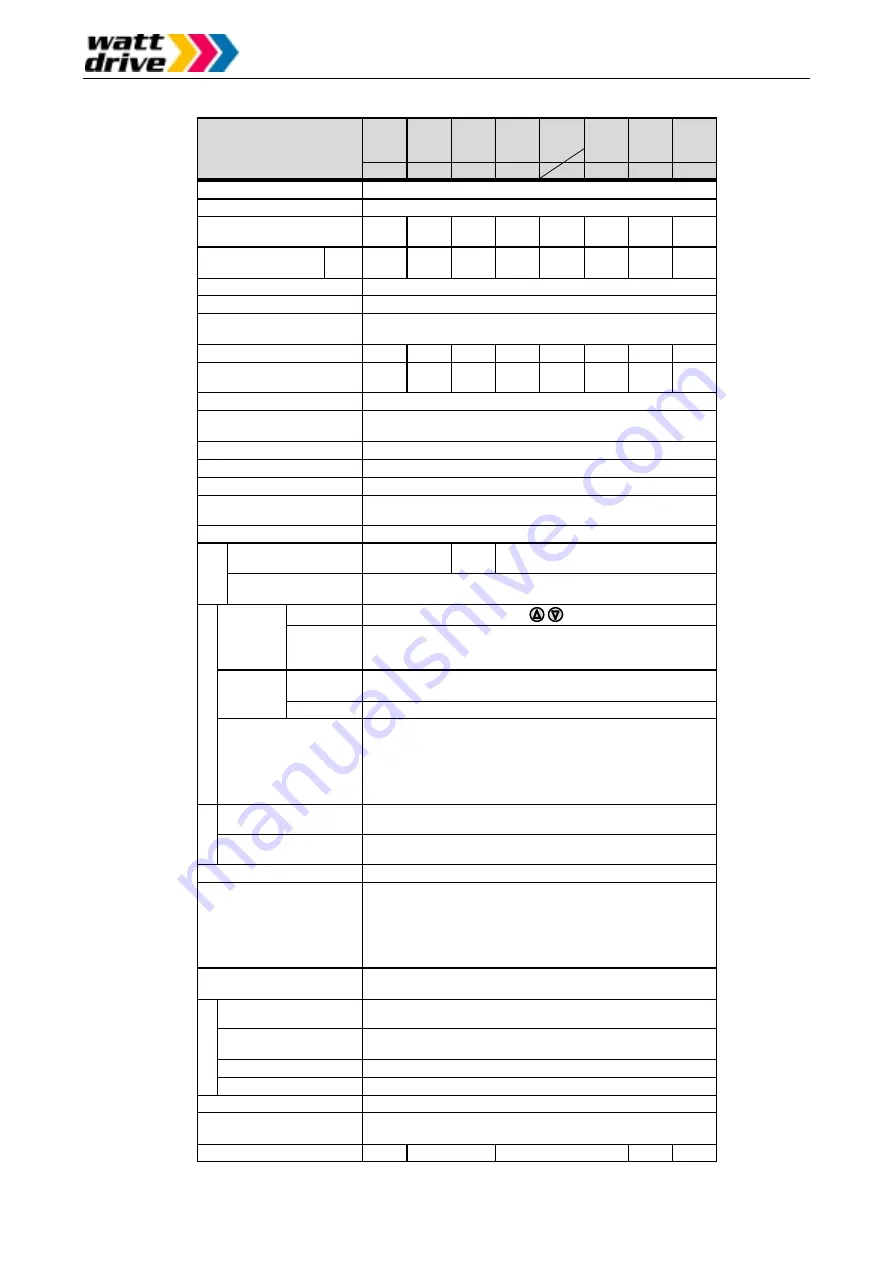

Appearance and names of parts

Page 16 / 52

004

HFE

007

HFE

015

HFE

022

HFE

030

HFE

040

HFE

055

HFE

075

HFE

Inverter L 2 0 0 0

-

(400V series)

Protective structure (

Note 1

)

IP20

Overvoltage category

III

Maximum motor size (4P)

in kW (

Note 2

)

0.4

0.75

1.5

2.2

3.0

4.0

5.5

7.5

Maximum capacity

in kVA

460V

1.1

1.9

3.0

4.3

6.2

6.8

10.3

12.7

Input supply phase

004 ~ 075HF: 3 phase

Rated input voltage

380VAC –10% ~ 10% 50/60Hz +/-5%

Rated output voltage

(

Note 3

)

Three phase 380 ~ 460VAC

(Corresponds to input voltage)

Rated input current in A

2.0

3.3

5.0

7.0

10.0

11.0

16.5

20.0

Rated output current in A

(

Note 4b

)

1.5

2.5

3.8

5.5

7.8

8.6

13.0

16.0

Output frequency range

0.5 ~ 360 Hz (

Note 5

)

Frequency accuracy

(at 25°C +/-10°C)

Digital command: +/-0.01% of maximum frequency

Analog command: +/-0.2% of maximum frequency

Frequency setting resolution

Digital setting: 0.1

Hz Analog setting: maximum frequency /1000

Voltage/frequency characterist.

Constant or reduced torque with any variable voltage/frequency

Overload current capacity

150% during 60 seconds (once per 10 minutes)

Acceleration/deceleration time

0.1 ~ 3000 s in selectable linear and non-linear mode

(second acceleration/deceleration usable)

Starting torque

100% ore more (when torque boost has been set)

Dynam. braking, feedback

to capacitor (

Note 6

)

ca. 100%

ca.

70%

ca. 20%

DC injection braking

Braking is on at the minimum frequency or less (minimum

frequency, braking time and braking force can be set)

Dig. operator

Settings using keys or potentiometer

Frequency

setting

External

signals

0-10VDC (input impedance 10k Ohm)

4-20mA (input impedance 250 Ohm)

Potentiometer 1k-2k Ohm, 1W

Dig. operator

Via keys RUN (for start) and STOP/RESET (for stop)

(Default setting: forward run)

Forward /

Reverse run

(Start/Stop) Ext. signals

Intelligent input terminals configurable as FW and RV

Intelligent input terminals

programmable as

FW: Forward run start/stop

RV: Reverse run start/stop

CF1–CF4: Multistage speed

JG: Jogging command

AT: Analog current input selection

2CH: 2.Accel./decel. time

FRS: Free run stop

EXT: External trip

USP: USP function

RS: Reset

SFT: Software lock

PTC: Thermal protection

Intelligent output terminals

programmable as

FA1/FA2: Frequ. arrival signal RUN: Motor running signal

OL: Overload signal OD: PID deviation signal AL: Alarm signal

Frequency and current

monitoring

Connection of external analog meter (0-10VDC, max. 1mA) for

frequency or current; connection of external digital frequency meter

Fault alarm contact

On when the inverter trips (1c contact)

Other functions

Automatic voltage regulation,

retry;

analog gain/vias adjustment,

frequency jump,

upper/lower limiter,

output frequency display,

trip history monitoring,

carrier frequency setting,

PID control,

automatic torque boost,

and many more

Protection functions

Overcurrent, overvoltage, undervoltage, electronic thermal,

temperature abnormality, ground fault upon starting, overload limit

Ambient temperature

(

Note 7

)

-10 ~ 50°C

Storage temperature and

humidity

-25 ~ 70°C (during short term transportation period only)

20 ~ 90% RH (no dew condensation)

Vibration

Max. 5.9m/s

2

(=0.6g) at 10-55Hz

Installation location

1000m or less altitude indoors (IP54 or equivalent)

External color

Blue

Options

Remote operator, copy unit, cable for digital operator,

reactor for improving power factor, noise filter

Overall weight (approx.)

1.3

1.7

2.8

5.5

5.7

Br

aki

ng

to

rque

In

pu

ts

Ou

tp

ut

s

En

vi

ro

nm

en

ta

l.