F-1031, Section 4307

Page 2 of 12

Disassembly of the Transmission

The transmission consists of three sections; the cap, the mid-section and the

bottom section. The order of disassembly is bottom section, mid-section and

cap.

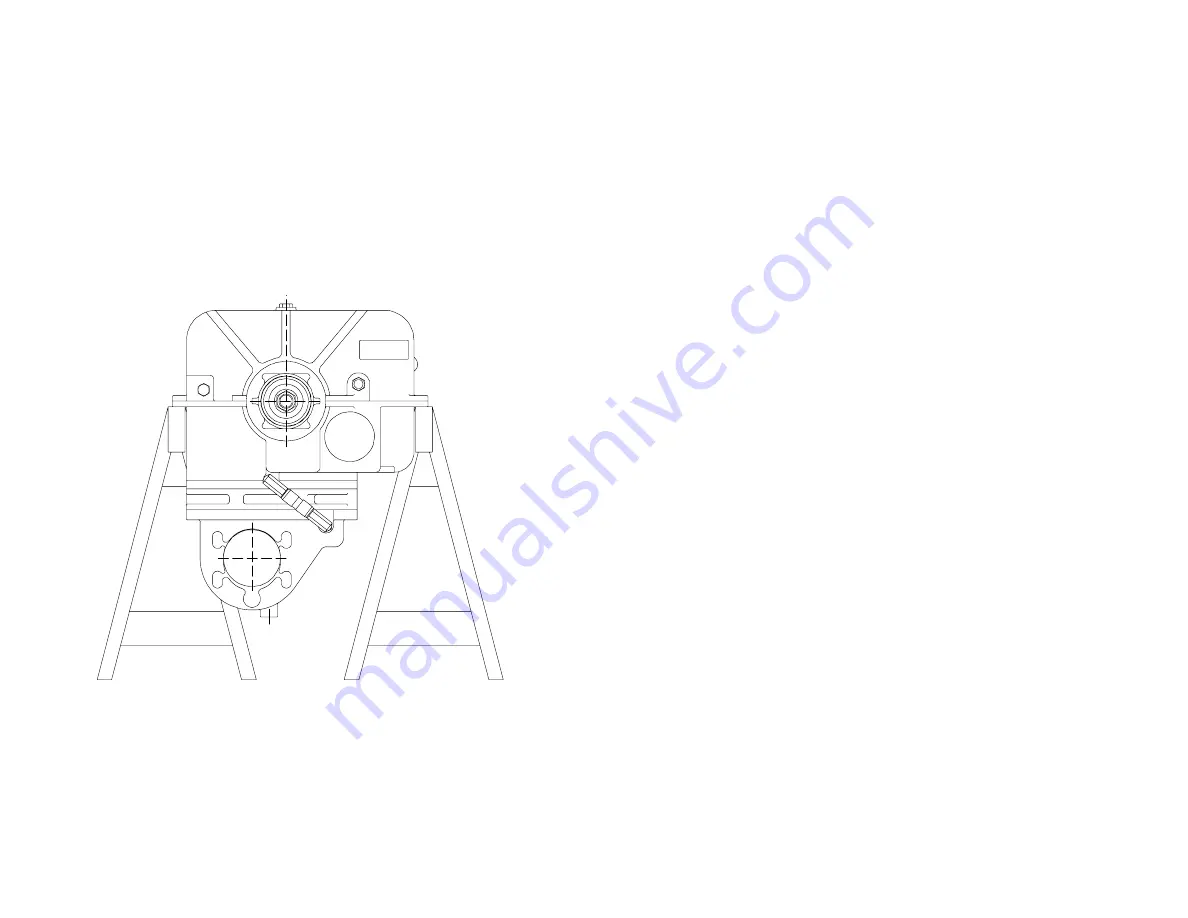

NOTE: Out of chassis overhaul will require supporting the transmission

initially in an upside down position, possibly attaching it directly to an

engine overhaul stand at the face of the cap that bolts to the pump or

making up an adapter to allow this connection to an overhaul stand.

Another consideration would be to support on the underside of the

flange of the mid-section, first removing the flange bolts at the support

areas (see Figure 1).

Figure 1. Transmission Supports

IL2153

1.

Remove companion flanges or end yokes from drive and coupling shafts.

2.

Remove lube systems hoses by disconnecting hoses (T67) and (T64) at

swivel fittings (T66), tee (T102) and elbow (T57). Remove sump oil

strainer (T132) from bottom section of case (T28).

3.

Remove cap screws (T8 prior to 5/06/04 or T241 after 5/06/04) and lock

washers (T9) attaching drive shaft housing to bottom section. Loosen cap

screws (T8 and T241) attaching housing to mid-section.

4.

Remove cap screws (T8 on 2” or 2.35” before 5/06/04 - T241 after

5/06/04) attaching the coupling shaft housing (T42) to mid-section and

case bottom.

5.

Remove coupling shaft housing (T42), shims (T41) and O-ring (T182 after

4/25/93).

NOTE: Remove coupling shaft, components and housing as a unit

from case by pulling on the shaft while tapping side to side on the

housing.

6.

Remove cap screws (T52), bolts (T93) nuts (T69) and lock washers (T53)

attaching bottom section to mid-section. Drive dowels (T131) from bottom

section. Separate bottom section and mid-section.

7.

Rotate drive sprocket (T5) and chain (T18) until removable connection pin

set (T83) of the chain is visible. The pin set has a spring pin (T108) in

each end holding it in place (see Figure 8).

8.

Remove spring pin (T108) from drive shaft housing side of long connecting

pin, tap both connecting pins from the chain. Disengage chain (T18) from

the drive (T5) and driven (T26) sprockets and remove from case.

Mechanical Tachometer

9.

Remove tachometer driven gear sleeve (T90) and driven gear (T89) from

drive shaft housing (T11).

Electronic Tachometer

10. Remove magnetic pick-up (T180) from drive shaft housing (T11).

11. Remove the remaining cap screws attaching the drive shaft housing (T11)

to the mid-section. The housing (T11), drive shaft (T13), drive sprocket

(T35), shift collar (T4), shift fork (T80) and associated parts can be lifted

out of the mid-section. The shift fork (T80) will slip off the shaft (T46) as

the parts are lifted up as an assembly. Remove shifter shoe (T40) from

locking arm (T38).

12. Remove locking arm (T38) from pivot pin (T37). Note that the pivot pin

(T37) and shift shaft bushings (T112) need only be removed if bent or

otherwise damaged.

13.

Electric Shift Cases:

Remove pin (T54 - prior to 12/20/02) or shoul‐

der bolt (T237) and self-locking nut (T238 - after 12/20/02) from sector

gear (T47). Remove sector gear from shift shaft. The removal of the pin

(T54) or shoulder bolt (T237) will release the tension on the shift arm

spring (T61). Remove shift shaft spring (T61). Remove sector gear (T47)

from shift shaft.

Summary of Contents for Y Series

Page 14: ......