4

TRUCLIMATE 500 INSTALLATION GUIDE

General Installation Information: Refrigerant Detection and Mitigation

Example: For instance, if your elevation is 5249Ft (1500mm)

your area factor would be 1.12. If your charge weight is 80oz

(2.268 kg) at a floor height installation. The Amin would be

516 square Ft (48.0 square meters). Take 516 square ft x 1.12

for a new Amin of 577.92 square feet (53.76 square meters).

H

alt

AF

meter

ft

0

0

1.00

200

656

1.00

400

1312

1.00

600

1969

1.00

800

2625

1.02

1000

3281

1.05

1200

3937

1.07

1400

4593

1.10

1600

5249

1.12

1800

5906

1.15

2000

6562

1.18

2200

Not recommended

2400

2600

2800

3000

3200

In cases where the minimum room area cannot be met, venti-

lation must be provided from either the equipment enclosure,

natural ventilation to the adjacent space, or provide mechani-

cal ventilation in the room.

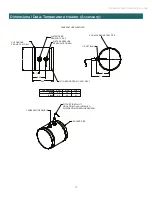

2. Machine Room

Equipment containing R-454B refrigerant may be installed,

operated, and stored in a machinery room and shall comply

with applicable sections of ANSI/ASHRAE 15 (USA) or CSA

B52 (Canada). To intergrate the mitigation control at the room

level into the unit leak detection control, see Figure C for

require field wiring instructions.

3. Ventilated Room

Equipment containing R-454B refrigerant shall be installed,

operated, and stored in a room with floor area larger than the

area defined in the “Minimum Floor Area” chart based on the

total refrigerant charge in the system per UL60335-2-40. This

requirement applies to indoor equipment with or without a

factory refrigerant leakage sensor. If a permanent vent is used

to exhaust air from A1 to EAmin, Qmin, the minimum volumet-

ric fl ow of air is provided in Table 1.

Refrigerant Leak Detection and Mitigation

Each chiller unit is provided with A2L leak detection sensors

and alarm output from the Aurora Control. This allows the leak

detection strategy to occur at the chiller unit level and the

leak mitigation strategy to occur at either the room level or

the chiller unit/bank level depending on the application.

Room Ventilation Method

.*"'$!#

##

! $!#(

/*"'$!#

"#

(

0*"'$!#

##

! $!#(

###!$!

!%"

!!#*

#"&#

3-002+/+1-)$!#!

#*

#$"#'

&#.2

! $!#"*

#"&#

3-002+/+1-)$!#!

#*

1. Unventilated Room

Determine the total refrigerant charge in the system. In pack-

aged systems, the factory charge should be the total charge

for the system and there should not be a reason for adding

charge in the field. The equipment serial plate and unit Physi-

cal Data table should serve as reference for the total charge.

Use Table 1 to determine the minimum floor area, Amin.

The equipment must be installed with a minimum floor area

equal or larger than the area listed in the chart based on the

total refrigerant charge of that system. If the area is not large

enough, you must move to next step for additional installation

requirements.

When the location of the installation is above 1969 ft (600m),

the Altitude Adjustment Factor in the table is needed to cal-

culate the minimum room size”.

Check that cabling will not be subject to wear, corrosion, excessive

pressure, vibration, sharp edges or any other adverse environmental

effects. The check shall also take into account the effects of aging or

continual vibration from sources such as compressors or fans.

WARNING

.

/

0

!#

#

Permanent

Vent

MODULAR CHILLER BANK

FLOOR AREA, A

1

EA

min