8

9

OPERATING DISPLAYS AND MAINTENANCE:

1 . GENERAL OPERATION:

When the system is operating, one of five displays may be shown and will alternate with the installing dealer’s name

and phone number for future service. Pressing

NEXT

will alternate between the displays.

1.

Time of Day Screen:

Displays the current time of day, the day of the week, and flow rate. Letter indicates which tank is in service.

2. Flow Rate Screen:

Displays the current treated water flow rate through tank A or B in Gallons Per Minute.

3. Capacity Remaining Screen:

Displays the amount of gallons of treated water remaining for the tank in service until the system triggers a

regeneration and switches to the other tank.

4. Days to a Regen Screen:

Displays the number of days until the system triggers a regeneration. Based on the days override value.

5. Dealer Name Screen:

Displays dealer specific name and phone number. This scrolling display will only appear if set by the dealer.

2 . REGENERATION MODE:

Typically a twin system regenerates when the capacity of the tank

providing treated water reaches zero remaining gallons. At this time, the online tank will transfer and

put the standby tank online so there is no disruption of treated water. Once this transfer is complete,

the depleted tank will regenerate and return to standby mode ready to enter service upon depletion

of capacity of other tank. This two tank configuration provides for a continuous, uninterrupted supply

of conditioned water at all times. When the system begins to regenerate, the display will change to

include information about the step of the regeneration process and the time remaining for that step to

be completed. The system will run through all remaining steps automatically and will reset to provide

treated water when the regeneration process has been completed.

3 . MANUAL REGENERATION:

Sometimes there may be a need to regenerate a unit before the control valve

calls for it. This may be needed if the system has been operating without salt for an extended period of time.

• To initiate a manual regeneration immediately, press and hold the

REGEN

button for three seconds. The

system will begin to regenerate immediately.

This command cannot be canceled.

Once a manual regeneration is initiated, the unit will transfer to the second tank in order to supply conditioned

water. Upon transfer, the depleted tank will begin its regeneration.

4 . POWER LOSS AND BATTERY REPLACEMENT:

If an extended power outage occurs, the control

valve will retain the time of day settings until the board’s battery is depleted. Once the battery is

depleted, the display will appear dark and absent of any information. If this occurs, following these steps

will determine if the problem is a low battery or a board failure.

To determine if the battery is depleted:

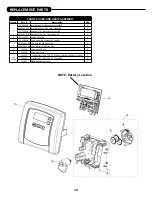

1. Remove valve cover. Disconnect power from PC Board at the four pin connector at the bottom

of the board.

2. Wait five minutes for board to de-energize. Remove battery with a non-conductive/non-metallic

material. Reference the Parts Breakdown section of this manual for location.

3. Wait five minutes for board to de-energize.

4. With the battery out, re-connect the power supply to the board. The board’s display should

begin to show information.

This indicates that the board is operating correctly. If the display does not work, call installing dealer for service.

5. To replace with new battery, unplug transformer from outlet. Install a 3 volt Lithium Coin Cell type 2032 battery, available at most stores.

Plug unit back into outlet.

It is important to replace the battery with the valve unplugged to avoid causing a short and potentially ruining the board.

6. Reset the time of day (see programming procedures) and initiate regeneration (see operating displays and maintenance).

If these procedures do not remedy the problem, please consult the installing dealer for service.

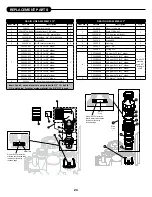

REGENERATION MODE

BACKWASH

8:22

Current Regen

Cycle Stage

Time Remaining

in Stage

MANUAL REGEN

REGEN TODAY

MON

GPM

2:40

8

PM

REGEN TODAY

and

TIME OF DAY

will flash alternately if a regeneration

is expected tonight.

TIME OF DAY

MON

GPM

2:40

A

PM

1

FLOW RATE

GPM

8.0

A

CAPACITY REMAINING

GPM

GAL

1600

A

DAYS TO A REGEN

GPM

3

A

555 5555555

DEALER NA

4

2

5

3

BATTERY REPLACEMENT

Summary of Contents for ASP-TW

Page 16: ...16 This page intentionally left blank...

Page 17: ...17 This page intentionally left blank...

Page 20: ...20 REPLACEMENT PARTS...