8

FLUSHING OF SYSTEM:

To flush the system of any debris and air after installation is complete, please perform the following steps:

1. Rotate bypass handles to the bypass mode

(Fig. 2 on page 4)

.

2. Turn on inlet water and check for leaks in the newly installed plumbing.

3. Fully open a cold water faucet, preferable at a laundry sink or bathtub without an aerator.

4. Wait two to three minutes or until water runs clear, then turn water off and follow start-up instructions.

Below is the name of each cycle as it appears on the screen with a description of the cycle position. The timing of each cycle will vary

depending on the unit size as set from the factory.

Name

of

Cycle

Description

BACKWASH

BACKWASH

REGENERANT DRAW DOWN

BRINE DRAW AND SLOW RINSE

RINSE

RAPID

RINSE

FILL

BRINE

TANK

FILL

1. With the softener in the bypass mode

(Fig. 2 on page 4)

and the control valve in normal operation where the

display shows either the time of day or the gallons remaining, manually add 8” of water to the regenerant tank.

NOTE:

If too much water is put into the brine tank during softener start up, it could result in a “salty water”

complaint after the first regeneration. During the first regeneration, the unit will draw out the initial volume of brine/regenerant and

refill it with the correct, preset amount.

2. With the softener in bypass mode, press and hold the

�����

button until the motor starts. Release button. The display will read “Pend 0” for

about three seconds while the system transfers from one tank to another. After the transfer is complete, the valve will automatically advance

to the “Backwash” position. Once the valve has stopped in this position, unplug the transformer so that the valve will not cycle to the next

position. Open the inlet handle of the bypass valve very slightly, allowing water to fill the tank slowly in order to expel air from the tank.

CAUTION: If water flows too rapidly, there will be a loss of media to the drain.

3. When the water is flowing steadily to the drain, clear and without the presence of air, slowly open the inlet valve.

Restore power and momentarily press the

�����

button to advance the control to the “BRINE” position.

4. With the bypass now in diagnostic mode

(Fig. 3 on page 4)

, check to verify that water is being drawn from regenerant tank with no air leaks

or bubbles in the brine line. There should be a slow flow to the drain. Disconnect brine line from the safety float valve in the brine tank and

check for a vacuum. After proper confirmation, reconnect brine line, making sure to tighten securely.

5. Momentarily press

�����

again until the display reads “RINSE.” There should be a rapid flow to the drain. Unplug transformer to keep

the valve in the “RINSE” position. Allow to run until steady, clear and without air. While the unit is rinsing, load the brine tank with water

softener salt

(refer to Brine Tank Maintenance and Salt section)

. Restore power.

6. Push

�����

again and the unit will advance to the “Brine Refill” position. Check to make sure the brine tank is refilling.

The flow rate is usually .5 gpm for all residential and light commercial applications.

7. Push

����

and the unit will return to normal operation.

8. Place unit into bypass mode again

(see Fig. 2 on page 4)

and press and hold the regen button to allow control valve

to transfer to the second tank. Follow steps 2-7 to now expel air from this tank.

9. When finished expelling air from second tank, return bypass handles to normal operating position

(see Fig. 1 on page 4)

.

The unit is now online and soft water is available for use.

10.

CONDITIONING OF MEDIA To flush any remaining debris and air from the system again:

1. Fully open a cold water faucet, preferably at a laundry sink or bathtub without an aerator.

2. Wait two to three minutes or until water runs clear, then turn water off.

3. Turn on hot water and check for air, then turn water off after air is discharged.

11.

SANITIZING OF UNIT UPON INSTALLATION AND

AFTER SERVICE

:

At this time, it is advised to sanitize the softener:

1. Open brine tank and remove brine well cover.

2. Pour 1 oz. of household bleach into the softener brine well.

NOTE:

Avoid pouring bleach directly onto the safety float components in the brine well.

3. Replace brine well cover.

Unit sanitizing will be complete when the first cycle is run and the bleach is flushed from the softener.

12. Check time of day. Start-up is now complete.

START-UP INSTRUCTIONS

Summary of Contents for ASP-TW

Page 16: ...16 This page intentionally left blank...

Page 17: ...17 This page intentionally left blank...

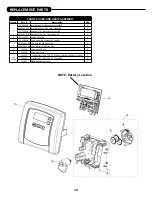

Page 20: ...20 REPLACEMENT PARTS...