7

5. Add water to the brine tank (initial fill). With a

bucket or hose, add approximately 4 gallons

(15 liters) of water to the brine tank. If the tank has

a salt platform above the bottom of the tank, add

water until the level is approximately 1 inch (25 mm)

above the platform.

Figure 7 - Air Check

Open the water supply valve slowly to the fill open

position. Carefully rotate the camshaft

COUNTERCLOCKWISE

until the indicator on the

regeneration cycle indicator points directly to the

center of the REFILL position and hold there until the

air check (Figure 7) fills with water and water flows

through the brine line into the brine tank. Do not run for

more than two minutes. Rotate the camshaft

COUNTERCLOCKWISE

until the indicator points to

the center of the BRINE/SLOW RINSE position.

Check that water is being drawn from the brine tank.

The water level in the brine tank will recede very slowly.

Observe the water level for at least three minutes. If the

water level does not recede, if it goes up, or if air enters

the transparent air check chamber and the ball falls and

seats, refer to the Troubleshooting section in this

manual.

When the water is being drawn from the brine tank,

rotate the camshaft COUNTERCLOCKWISE until the

indicator points to REGEN COMPLETE. Run water

from a nearby faucet until the water is clear and soft.

Connecting the Control

The control has default values for most parameters that

were set at the factory, but there are key items that

need to be entered at the time of installation:

•

Time of Day

•

Time of Regeneration

•

Hardness

•

Salt Amount

•

Capacity of the Unit

•

Refill Controller Value

•

Brine Draw Rate

Determine from Tables 1 and 3 what these values

should be before applying power to the control. It is

also helpful to read the Programming the Model 960

Control

section if you want to set other parameters.

When the conditioner is operational, complete the

following steps to connect the Model 960 control:

•

Connect the control to the wall transformer

cable. The power connection is located on the

underside of the control on the left side (refer to

Figure 1). Insert the barrel style connector into

the power plug.

•

Plug the wall-mount transformer into an

electrical outlet that is not controlled by a wall

switch.

•

If the cord length of the transformer is too short,

an optional 15-foot low voltage extension cord

may be purchased (contact your original

equipment dealer for details) or the wire may be

spliced as shown in Figure 19 on page 24.

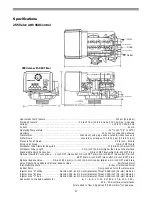

Figure 8 - Faceplate of 960 Control

Programming the Model 960 Control

This section covers all aspects of programming the

control. The control is shipped from the factory with

default values for Hardness and Capacity. These

default values will result in a system capacity of

100 gallons (1 cubic meter). While the control will

operate with these values, they should be changed to

meet the actual operating conditions.