11

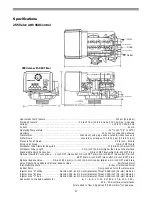

Table 3 - Programming Parameters

Parameter

Name

Description

Range of

Values

Minimum

Increments

Default

Units of

Measure

Notes

P6

Refill

controller

1 to 99

1

33

Enter the value molded into

the end of the refill controller.

P7

Brine draw

value

1 to 99

1

25

Select number from Table 4

and enter that number.

P8

Not used

NA

NA

NA

NA

NA

P9

Backwash

time

3 to 30

1

14

Minutes

Skip this parameter to accept

the default or enter a value.

P10

Slow rinse

time

8 to 125

1

40

Minutes

Skip this parameter to accept

the default or enter a value.

P11

Fast rinse

time

2 to 19

1

4

Minutes

Skip this parameter to accept

the default or enter a value.

P12

Units of

Mmeasure

0 to 1

1

0

0 = U.S., 1 = Metric. Skip this

parameter to accept U.S. or

enter 1 for Metric.

P13

Clock mode

0 to 1

1

0

0 = 12-hour clock.

1 = 24-hour clock. Skip this

parameter for a 12-hour clock

or enter 1 for a 24-hour clock.

P14

Calendar

override

0 to 30

1

0

Days

0 = no calendar override. Skip

this parameter for no calendar

override or enter a value.

P15

Reserve type

0 to 3

1

0

0 = variable reserve, 1 = fixed

reserve, 2 = variable reserve

with immediate regen,

3 = fixed reserve with

immediate regen. Skip this

parameter to accept the

default or enter a different

reserve type.

P16

Fixed reserve

capacity or

initial average

value

0 to 70

1

30

Percent of

capacity

Description depends on the

value entered for P15. Skip

this parameter to accept the

default or enter a different

value.

P17

Operation

type

0 to 1

1

0

0 = 5-cycle counter or co-

current conditioner, 1 =

reserved for future use.

P18

Salt/capacity

change

Lockout

0 to 1

1

0

0 = none, 1 = salt/capacity

change locked out. Skip this

parameter to accept the

default or enter 1 to lock out

salt/capacity change.

P19

Factory

defaults

0 to 3

1

9

Loads in a set of default

values. Refer to the Special

Notes for Level II

Parameters

section in this

manual.