WINCH MANUAL

RIGGING TECHNIQUES

6

1. Your winch is designed with a bolt pattern that is standard in

this class of winch. Many winch mounting kits are available that

utilize this bolt pattern for the most popular vehicle and mounting

channels. If you cannot find a kit locally, contact us and we will

provide you with the name of a dealer near you. If you utilize the

mounting channel, you must ensure that it is mounted on a flat

surface so that the three major sections (motor, drum and gear

housing) are properly aligned. Proper alignment of the winch will

allow even distribution of the full rated load and reduce the chance

of damaging winch or equipment. Poor installation contributes to

approx 90% equipment or winch damage.

2. Start by connecting the Roller Fairlead to the Mounting Channel

using 2 each of the Cap Bolt M10 X 35, Flat Washer, Lock Washer

and securing with M10 Nut (Make sure the bolt is placed through the

mounting channel and roller fairlead from inside the channel. This

will allow enough clearance for the winch to be placed in the channel

without obstruction.)

3. Assemble the winch to the (optional) Mounting Channel by first

pulling and releasing the clutch knob to “Out” position (Free

Spooling). Pull out a few inches of cable from the drum and feed the

wire loop through the opening in the front of the mounting channel

and roller fairlead. Now, using the remaining M10 x 35 Cap Bolts, Flat

Washer, Lock Washer, and M10 Nut secure the winch to the mounting

channel.

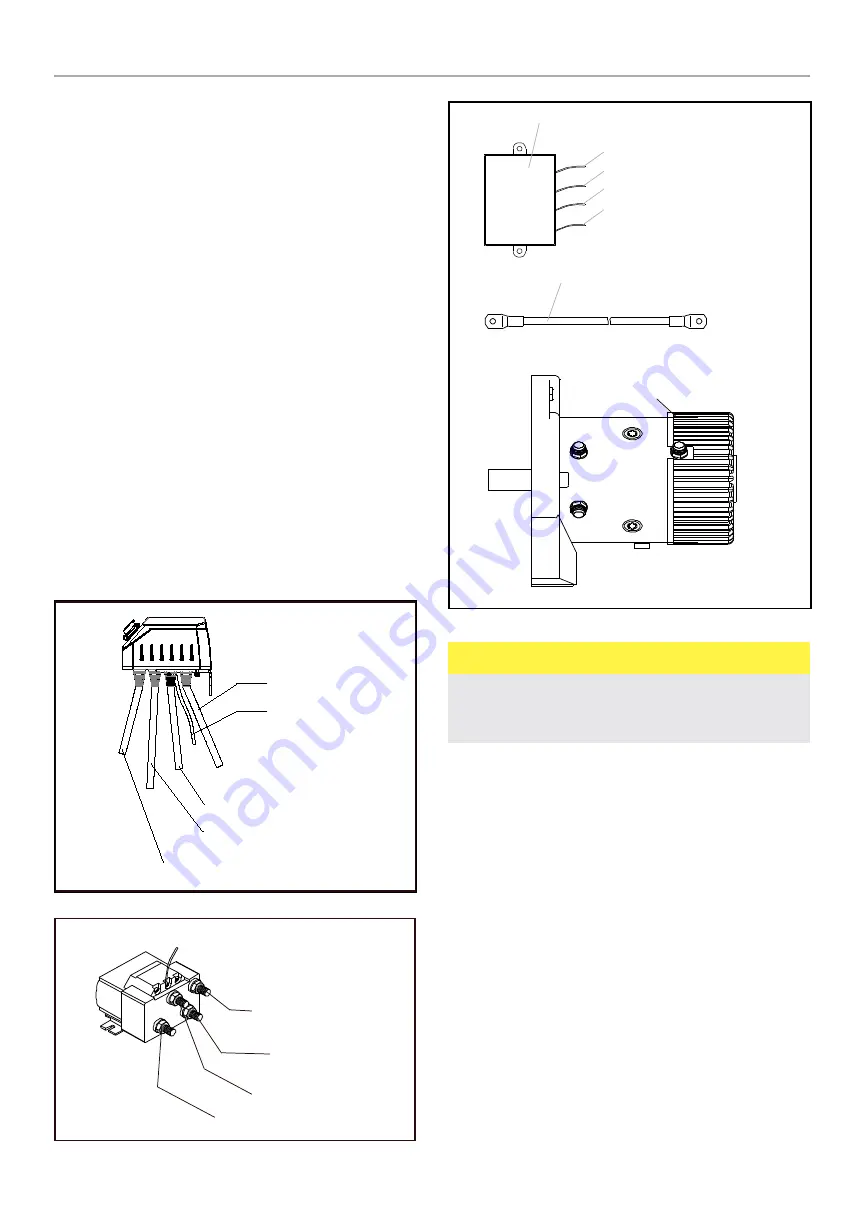

4. Connect the battery and motor leads as the drawing above.

Remember every type of winch is different.

5. Connect the winch motor as detailed below:

Black long wire assembly (connect

the earth terminal on the motor)

Connect to Motor F1 (Yellow)

Connect to Battery Po

Connect to Motor F2 (Red)

Connect to Motor A (Blue)

Black long wire assembly (connect the earth

terminal on the motor)

Connect to motor F2 (Red)

Connect to Motor F1 (Yellow)

Red long wire assembly. Connect to

battery po

Connect to Motor A (Blue)

WIRELESS SWITCH RECEIVER

White wire - connect to relay J3

Yellow wire - connect to relay J1

Red wire - connect to relay J(+)

Black wire - connect to relay J2

Red (F2)

Blue (A)

Yellow (F1)

Black wire assembly - connect to motor’s earthing terminal

and battery negative -

Motor’s earthing terminal

MOTOR

CAUTION

Batteries contain gases which are flammable and explosive. Wear eye

protection during installation and remove all jewelry. Do not lean over

battery while making connections.

6. Assemble the Clevis Hook to the cable. Take off the pin from the

Clevis Hook, connect the Clevis Hook to the cable and mount the pin

back to the Clevis Hook.

7. Always use the Hand Saver (Optional) when free-spooling and re-

spooling the wire rope. Using the Hand Saver keeps your hands and

fingers away from the rotating drum.

8. Check for proper drum rotation. Pull or turn the clutch knob to the

“OUT” “Disengage” position (Free-spooling). Pull out some cable

from the drum, and then turn the clutch knob to the “IN” “Engage”

position to engage the gears. Press the cable out button on the

remote lead switch. If the drum is turning and releasing cable, then

your connections are accurate. If the drum is turning and collecting

more cable, then reverse the leads on the motor. Repeat and check

rotation.

RIGGING TECHNIQUES

Locate a suitable anchor such as a strong tree trunk or boulder.

ALWAYS use a sling or strap as an anchor point on a object, Never use the

cable or hook as a anchor point attached to an object.