4

2600 Emrick Blvd • Bethlehem, PA 18020 • USA • 800-922-0085 • www.warrencontrols.com

SET UP & GENERAL SAFETY

With power applied, preferably, use a signal calibrator to

verify that the valve is fully stroking from one end to the

other as depicted by the travel indicator on the side of

the actuator mounting Pillar and with the proper control

action. Alternately the process controller could be directly

connected to test if it has a ‘Manual-Mode’ of operation

where the controllers output can be manually adjusted from

0% - 100%.

IF THE ACTUATOR IS ONE WITH A DEFINED ‘FAIL-SAFE’

DIRECTION ,THAT CAN BE VERIFIED BY:

1. Using the signal calibrator to move the

actuator position to mid-stroke.

2. Safely disconnecting power at the power

breaker switch and observing the actuator

going to its fail-safe position.

Once these steps are verified you may proceed to

commissioning the control valve. If either of these tests did

not perform as expected, then contact the Warren Controls

factory for further troubleshooting steps.

BASIC SAFETY NOTES:

• Before opening the actuator cover, ensure that the electrical

mains supply voltage is disconnected.

• If operating the actuator with the cover removed for

troubleshooting reasons make sure the wiring terminations

are clearly understood. Contract the Warren Controls factory

for further troubleshooting steps as may be necessary.

• Do NOT attempt to auto-stroke the actuator when the

actuator is not connected to a control valve as it will not

function.

• Do NOT adjust the Manual Override completely downward

when the actuator is not connected to a control valve as this

could permanently damage the actuator.

•If the actuator is removed from the control valve, upon

reinstallation the auto-calibration procedure must be

performed.

CONTROL SIGNAL AND POSITION FEEDBACK CHOICES AND LABEL DESIGNATIONS.

SIGNAL

2-WAY VALVE CLOSED

LABEL

DESIGNATION

3-WAY VALVE

LOWER PORT CLOSED

LABEL

DESIGNATION

4 – 20 mA

@ 4 mA

20 – 4 mA CL

@ 4 mA

20 – 4 mA DN

4 – 20 mA

@ 20 mA

4 – 20 mA CL

@ 20 mA

4 – 20 mA DN

0 – 20 mA

@ 0 mA

20 – 0 mA CL

@ 0 mA

20 – 0 mA DN

0 – 20 mA

@ 20 mA

0 – 20 mA CL

@ 20 mA

0 – 20 mA DN

2 – 10 Vdc

@ 2 Vdc

10 – 2 Vdc CL

@ 2 Vdc

10 – 2 Vdc DN

2 – 10 Vdc

@ 10 Vdc

2 – 10 Vdc CL

@ 10 Vdc

2 – 10 Vdc DN

0 – 10 Vdc

@ 0 Vdc

10 – 0 Vdc CL

@ 0 Vdc

10 – 0 Vdc DN

0 – 10 Vdc

@ 10 Vdc

0 – 10 Vdc CL

@ 10 Vdc

0 – 10 Vdc DN

‘Signal’ as 20-4 CL, to indicate it is a 4 – 20 mA signal and CLOSED at 4 ma. The actuator should be preprogrammed for control

action and which signal is designated. Switching from a milliamp signal to a voltage signal is simply a matter of wiring termination.

Switching whether the control signal is ZERO based or not, or the control action must be done in the software set up. This can

be done on the job site as necessary with the programming umbilical cord option along with a laptop computer that has a USB

connection. If this is required, contact the Warren Controls factory.

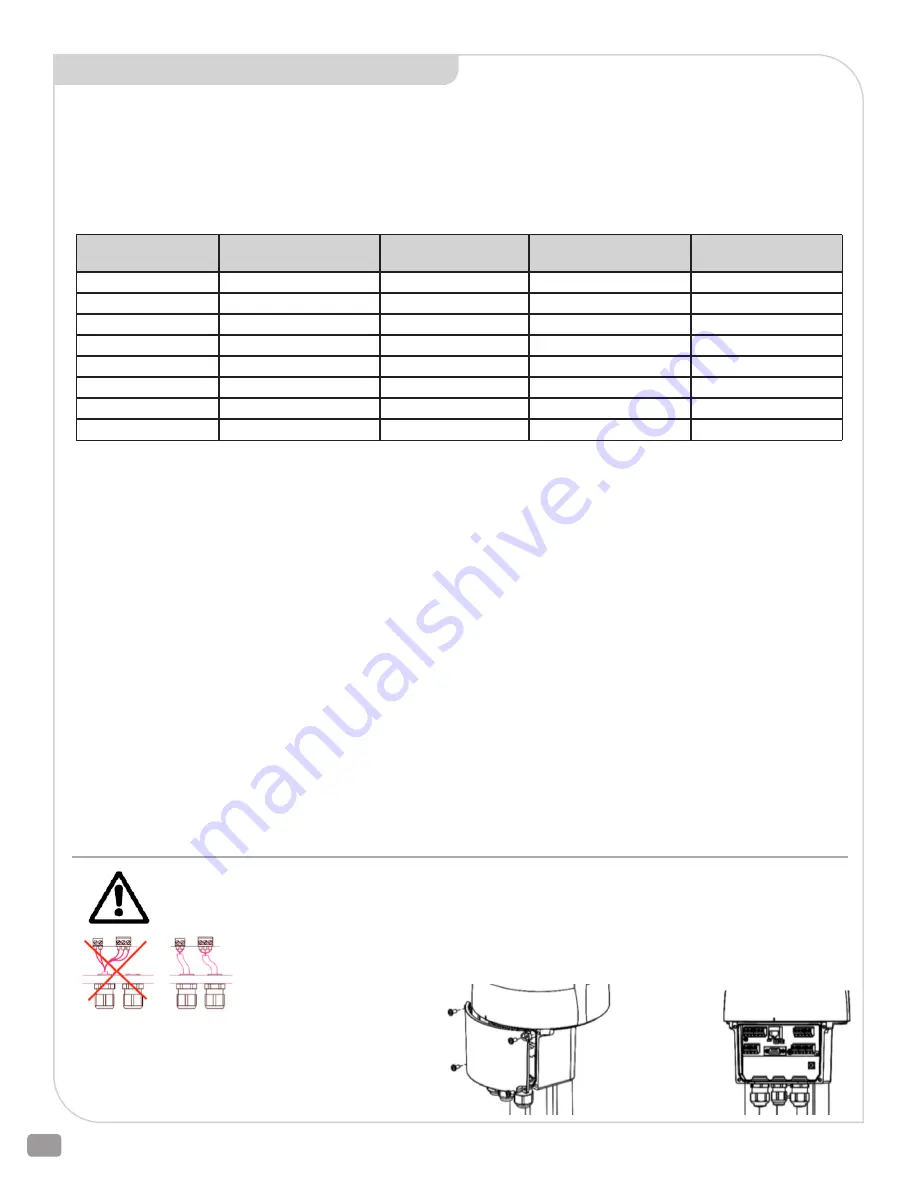

Electric installation as well as over-current and over-voltage protection devices must be conform to the standard

DIN IEC 60364-4-41, protection class I resp. protection class III (24VAC/24VDC) and also to the standard DIN IEC

60364-4-44 according to the applied over-voltage category of the actuator.

Please protect all of the power supply and control cables in front of the terminals mechanically by

using suitable measures against unintentional loosening.

Remove

connection

terminal cover

Never install the power supply and the control cables

together in one conduit but instead please always use

two different conduit.