14 June 2016

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior notification.

All Dimension are in mm………….Copyright ©

6

APPLYING THE VERMICULITE :

(Course—must be larger than the burner plates holes so not to block them)

Apply with care a thin layer of Vermiculite over the Burner, just enough to cover the Burner Tray only .

NOTE: If the burner flame is uneven, the Vermiculite may need to be changed or sifted to remove the smaller pieces that can block the burners

holes. The smaller pieces can ,cause uneven burn and the unit to run dirty.

COALS AND LOGS (To be set by Gasfitter)

VERMICULITE (COURSE) (To be set by Gasfitter)

Total Coals

Bottom

Top

Bottom

Top

Model

Total

SG EG 700

6

5

2

2

22

8

6

2

2

SG EG 780

28

SG EG 900

10

9

2

2

38

SG EG 1100

11

10

2

2

42

Number of Coals per Row

Number of Rows

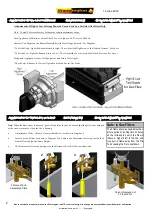

2 : Top Row

Slide R & LH Grate

Pins into Holes located

on the Burner Side

plates .

1 : Bottom Row

Gloves should be worn when handling Ceramic Fibre Coals & Logs : care needs to be taken when handling Coals & Logs , Due to the Carbon on the

Coals can stain the surroundings.

HELPFUL HINTS : When Hot use Metal Tongs

.

Apply a thin layer of Vermiculite over the Burner , just enough to cover the Burner Tray only as shown above.

1 : Bottom Row

: Assemble 2 Bottom Rows of Coals onto the Vermiculite Base .

2 : Top Row

: Assemble 2 Top Rows of Coals onto the Bottom Row .

Each Coal randomly positioned with the Torn (roughest) Face Outward .

Ensure Coal positioning does not directly block the 3 Flame Pilot .

The placement of the Coals & Logs may vary to make an even Flame Pattern .

Logs and Twigs may be scattered to achieve best Visual Effect .

Fit Burner Grate by sliding R & L Side Metal Pins on Grate, into Holes Located on Burner Side Plates , as shown below .

Model SG780 Shown: Total number of coals will vary per model.

General Coal orientation fro optimum effect.