10

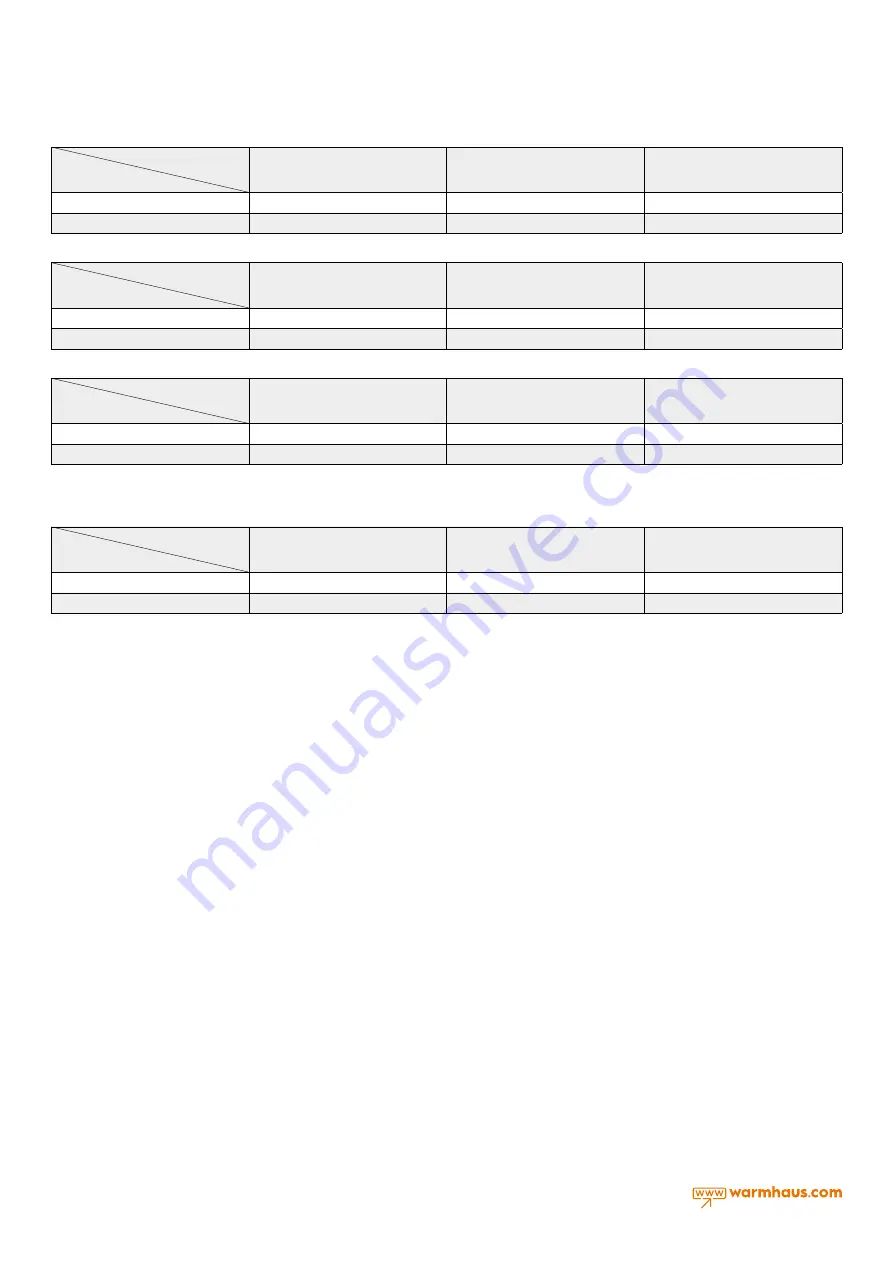

Room Sealed Appliances Installed within an Enclosure (Natural ventilation requirements direct to Outside Air)

System Type

Grille Location

600m from any obstruction

Heating &/or HWS

Operation < 50% during summer months

Heating &/or HWS

Operation > 50% < 75% during summer

months

Heating &/or HWS

Operation > 75% during summer months

High Level (Free Area/kW)

5 cm

2

6 cm

2

7 cm

2

Low Level (Free Area/kW)

5 cm

2

6 cm

2

7 cm

2

Room Sealed Appliances Installed within an Enclosure (Natural ventilation requirements Via an internal Space)

System Type

Grille Location

600m from any obstruction

Heating &/or HWS

Operation < 50% during summer months

Heating &/or HWS

Operation > 50% < 75% during summer

months

Heating &/or HWS

Operation > 75% during summer months

High Level (Free Area/kW)

10 cm

2

11 cm

2

12 cm

2

Low Level (Free Area/kW)

10 cm

2

11 cm

2

12 cm

2

Room Sealed Appliances Installed within a Boiler Room / Heated Space (Natural ventilation requirements direct to Outside Air.)

System Type

Grille Location

600m from any obstruction

Heating &/or HWS

Operation < 50% during summer months

Heating &/or HWS

Operation > 50% < 75% during summer

months

Heating &/or HWS

Operation > 75% during summer months

High Level (Free Area/kW)

2 cm

2

3 cm

2

4 cm

2

Low Level (Free Area/kW)

2 cm

2

3 cm

2

4 cm

2

Max Operating Pressure < 100mbar, Room Air Change Rate >0.5/hour = No Additional Ventilation. If the air change rate is less than 0.5/hour them

the following must be applied.

Appliances without draught diverters with or without draught stabilisers

System Type

Grille Location

600m from any obstruction

Heating &/or HWS

Operation < 50% during summer months

Heating &/or HWS

Operation > 50% < 75% during summer

months

Heating &/or HWS

Operation > 75% during summer months

High Level (Free Area/kW)

1.35 +/- 0.18 (m

3

/h/kW)

1.35 +/- 0.18 (m

3

/h/kW)

1.35 +/- 0.18 (m

3

/h/kW)

Low Level (Free Area/kW)

2.6 (m

3

/h/kW)

3.32 (m

3

/h/kW)

4.04 (m

3

/h/kW)

VENTILATION

“Viwa 90 - 150” boilers an be installed in boiler rooms whose size and

requirements meet current regulations. The following is provide for your

guidance only, and assumes the ventilation air is taken directly from

outside. The sizes of the vents may need to be increased inrespect

of other appliances installed in the same area, and seasonal use. Take

care that the position of low level vents would not subject to adverse

weather conditions, ie flooding.

Ventilation requirements for Viwa 90 -150 boilers and cascade systems.

BS6644 has a requirement that the temperatures in a room or

compartment do not exceed certain levels:

- +25 °C at floor level (0-100 mm)

- +32 °C at mid level (1.5 m above the floor level)

- +40 °C at ceiling level (0-100mm from ceiling)

When installed as a class B appliance (open flued, not roomed sealed).

Installed in a room High level (within 15% of the room height from

ceiling) - 2 cm²/kW of net heat input Low level (low as possible within

1 metre from floor natural gas ) – 4 cm²/kW of net heat input A single

Viwa 125 (116 kW net input) boiler would require 232 cm² at high level

and 464 cm² at low level. Installed in a compartment or enclosure

High level (within 15% of the room height from ceiling) - 5 cm²/kW of

net heat input Low level (low as possible within 1 metre from floor

natural gas) –10 cm²/kW of net heat input. A single Viwa 125 (116 kW net

input) boiler would require 580 cm² at high level and 1160 cm² at low

level. When installed as a class C appliance (room sealed). Installed in

a room High level (within 15% of the room height from ceiling) - 2 cm²/

kW of net heat input Low level (low as possible within 1 metre from

floor natural gas) – 2 cm²/kW of net heat input A single Viwa 125 (116

kW net input) boiler would require 232 cm² at high level and 232 cm²

at low level.

2.4. NATURAL GAS CONNECTION (DEVICE

CATEGORY I

2H

)

Our boilers were manufactured to run with methane gas (G20).

Gas supply pipes must be equal to or greater than 3/4 "G boiler

connections. Before connecting the gas, a careful internal cleaning of

the pipe laying of the entire fuel supply installation must be carried

out, since possible waste will damage the best performance and

efficiency of the boiler. It must be checked that the gas distributed

from the main line is in the type stipulated for the boiler (see the label

on the boiler).

In addition, the network dynamic pressure (methane) to be used

in feeding the boiler and in case of it is inadequate, that may

affect the power of the boiler and cause difficulties for the user.

Make sure the gas valve connection is made correctly. The

flammable gas supply pipe must be designed and dimensioned

according to the current MMO and local gas company

specifications and instructions in order to ensure that the boiler is

capable of delivering sufficient gas to the burner while the boiler

is operating at maximum power and the device is efficient. The

connection system must comply with legal regulations.

2.4.1. Flammable Gas Quality

The boiler is designed to be used with pure fuel which does not

contain foreign substance in; for this reason it is absolutely necessary

to add the necessary filter systems in the gas supply line (in order to

ensure that the fuel is purified).