12

warmhaus.co.uk

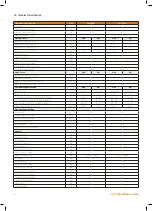

2.4. System Requirements

INFORMATION

The installation of this appliance must take into consideration all prevailing

regulations and codes of practice and the data in this manual.

This instruction manual and the below standards must be adhered to

throughout the installation

Building Regulations.

British Standards.

Irish Standards

Gas Safety Regulations.

Water Supply Regulations,

2.4.1. General

INFORMATION

The system must be to a minimum standard that meets all relevant criteria

and regulations at the time of the installation of this appliance.

All external components must be able to withstand a working pressure of 3

bar and a working flow temperature of 100 °C.

The system must be free of any leaks and in a suitable working condition

for the connection of a new appliance.

2.5. Water Supply (only for Combi Boiler)

INFORMATION

Appliance use in hard water areas:

In normal operating conditions there is no need to provide any water

treatment to prevent any limescale formation this is because the maximum

temperature of the DHW heat exchanger is monitored and limited by

electronic control.

In areas where the water exceeds 200 ppm it is advised that a scale

prevention should be installed, and you should contact your local water

authority for advice and guidance.

Installations that have non-return or backflow valves fitted on the cold

mains should have a mini expansion vessel fitted between the valve and

the appliance.

2.6. Gas Supply

INFORMATION

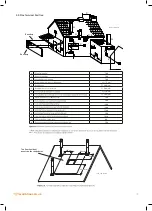

The gas installation should be in accordance with the relevant standards. In

GB this is BS 6891 (NG). In IE this is the current edition of IS 813 Domestic

Gas Installations.

The boiler must be installed on a supply from a governed gas meter.

The connection to the appliance is a 22mm copper tail located at the rear

of the gas service cock.

Ensure that the pipework from the meter to the appliance is of adequate

size, and the demands of any other gas appliances in the property are

taken into consideration. Do not use pipes of a smaller diameter than the

boiler gas connection (22mm) UNLESS the stated gas rate can be achieved

with pipe of lesser diameter and with all other gas appliances operating at

maximum rate.

Purging of any pipe work and the appliance must be carried out as outlined

in BS 6891.

2.6.1. By-pass

INFORMATION

The boiler incorporates a bypass by utilizing the primary circuit on the

DHW plate heat exchanger and uses this method as an integral bypass

system and therefore does not require as standard an external bypass fitted

to the system.

2.6.2. Ventilation

INFORMATION

The boiler does not require any additional ventilation and when installed in a

cupboard or compartment the boiler operates at an adequate temperature

without the requirement for additional ventilation. BS 5440: Part 2 refers

to this in detail.

2.6.3. Primary system cleaning

Debris in the existing heating system can cause damage to the boiler unit

correct cleaning has not been carried out.

2.7. Electric Supply

RISK OF ELECTRIC SHOCK

This appliance must be earthed.

This appliance must not be connected to a three-phase supply.

External wiring must be correctly earthed, polarised and in accordance with

relevant regulations/rules. In GB this is the current IEE Wiring Regulations.,

in IE this is Irish Standard IS 10101:2020

The mains supply is 230V ~ 50Hz fused at 3A.

Important:

The method of connection to the electricity supply must facilitate complete

electrical isolation of the appliance.

Connection may be via a fused double-pole isolator with a contact

separation of at least 3mm in all poles and servicing the boiler and system

controls only, alternatively the connection can be made via a fused 3 pin

plug to an un-switched shuttered socket both complying to BS1363

When working on the boiler the electricity must always be isolated and the

correct method of safe isolation must always be followed.

Any external controls connected to the boiler must have at minimum and

valid CE approval and be suitable for connection to the boiler.

Please ensure the correct RCD is fitted the circuit where the boiler is

connected electrically, due to the low energy DC modulating pump fitted

inside the boiler.

If you plan to replace the cable supplied with the boiler for the electrical

connection, please ensure the replacement cable meets the current

standard and it is the correct size and has the correct heat rating.

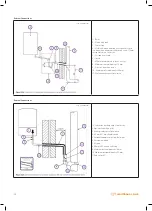

2.8. PRV Discharge

ATTENTION

The safety discharge pipe must be installed with a minimum pipe size

diameter of 15mm and be in copper or an other suitable material that can

withstand PRV discharge temperatures and pressures that comply with BS

5254 or BS EN 1451.

The PRV discharge terminal must terminate away from any electrical

hazards and terminate where it cannot cause injury to person, it should

terminate with a bend to face the external surface or into a suitable drain

point.

The PRV discharge can be installed into a waste pipe system and all

installations should follow the guidance of BS 6798 sections 6.

Due to maintenance of the PRV we require our copper connection pipe to

be connected to the external PRV pipe work by means of a compression

joint so that in all installations maintenance will be achievable without the

need to cut and re-join copper pipe work.

Where PRV terminations are not possible to visually see e.g. directly into

a waste pipe connection, then a tundish must be fitted so that and water

drips leaking from the PRV can be visually seen and the appropriate action

taken.

Care should also be taken when planning the termination of the PRV due

to the possibility of a slow and steady drip can discharge from the terminal

and if not correctly sited leave the possibility of water freezing when hitting

ground causing an extreme hazard if the frozen water is in the path of a

walk way.

Summary of Contents for EWA 2525C

Page 1: ...CONDENSING COMBI BOILERS INSTALLATION SERVICE MANUAL EWA 2525C 25 kW EWA 2530C 30 kW...

Page 2: ......

Page 3: ...3 warmhaus co uk...

Page 57: ...57 warmhaus co uk...