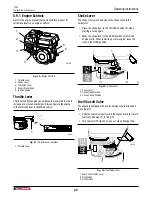

6.3 Grease Points

Use a hand-held grease gun for all greasing. Pump one shot

of grease slowly into each fitting.

•

Use an SAE multi-purpose high temperature grease with

extreme pressure (EP) performance. Also acceptable is an

SAE multipurpose lithium-based grease.

•

Wipe grease fitting with a clean cloth before greasing to

avoid injecting dirt and grit.

•

If fittings do not take grease, remove and clean them

thoroughly. Replace grease fittings as necessary.

Location

Grease Points

– Every 50 hours of operation

or annually

1

Driven shaft bearings–1 per side

Fig. 42 –

Grease Points

1

IMPORTANT! Do not over grease. Pumping more than

one shot from a grease gun into the bearings can push the

grease out of the seals. Doing that repeatedly can damage

the seals. Grease is not kept in, and dirt and moisture are

not kept out.

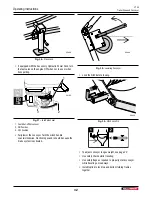

6.4 Conveyor Chain Tension,

Adjusting

The conveyor chain can stretch a slight amount and can require

occasional adjustment. Care must be taken the chain is not over

adjusted, as this adds pretension into the chain and reduces

chain life.

IMPORTANT! The main requirement of chain adjustment is

to remove slack from the chain (take up the clearances in

each link). It is easy to over tighten the chain, so great care

is needed!

Measure conveyor chain slack from the topside, inside the

conveyor trough. Pull the chain up at the middle and measure

dimension

X

. Adjust accordingly.

X

Ideal Conveyor Chain Slack (X)

16 ft (4.8 m) Conveyor

X = 4" (10 cm)

24 ft (7.3 m) Conveyor

X = 6" (15 cm)

00988

1 2

Fig. 43 –

Chain tensioner

1.

Loosen jam nuts (1).

2.

Turn spring tensioner nut (2) clockwise to increase chain

tension.

Make sure both sides of the conveyor are

adjusted equally.

NOTE:

It may be necessary to tap the bolt lightly to get

the spring to re-adjust the tension to the new

setting.

3.

Tighten jam nuts (1).

CT24

Trailer Firewood Conveyor

Service and Maintenance

35