Service and Maintenance

BX36S

3PH Self-feed Chipper

40

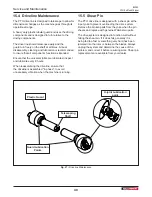

15.4 Driveline Maintenance

The PTO drive line is designed to telescope to allow for

dimensional changes as the machine goes through its

operational range.

A heavy duty plastic tubular guard encloses the driving

components and is designed to turn relative to the

driving components.

The drive line should telescope easily and the

guard turn freely on the shaft at all times. Annual

disassembly, cleaning and lubrication is recommended

to insure that all components function as intended.

Ensure that the universal joints are lubricated, inspect

and lubricate every 8 hours.

When reassembling the driveline, ensure that

the driveline is assembled "in phase", to avoid

unnecessary vibration when the machine is running.

15.5 Shear Pin

The PTO drive line is designed with a shear pin at the

input yoke to prevent overloading the drive system.

Remove the broken parts from the yoke when the pin

shears and replace with genuine Wallenstein parts.

The drive system is designed to function well without

failing the shear pin. If it does fail, generally it is

being fed too fast or something very hard has been

jammed into the rotor or between the blades. Always

unplug the system and determine the cause of the

problem and correct it before resuming work. Shear pin

replacements are available from your dealer

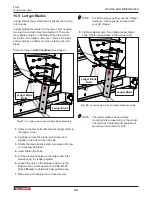

Plastic Guard

Guard Lubrication

Points

U-joint Lubrication

point

Telescoping

Shaft

Fig. 27 –

Driveline Maintenance

Summary of Contents for BX36S

Page 1: ...OPERATOR S MANUAL 3PHSelf feedChipper BX36S BX52S BX72S BX102S...

Page 51: ......

Page 52: ...www wallensteinequipment com...