31

TempSpray-H326 / -H226 / -H126

GB

1.4

ELECTRIC CHARGE (SPARK AND FLAME

FORMATION)

Due to the flow speed of the coating material

in the hose, there is the possibility of electro-

static charging at the equipment.

These can involve spark or flame formation at

discharge. Therefore it is necessary that the

Airless-unit is earthed according to directions

at all time.

1.5

EARTHING OF THE OBJECT

The object to be coated must be earthed.

(Building walls are usually earthed naturally)

1.6

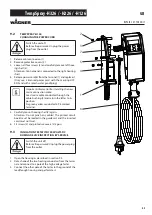

PROTECTIVE EARTHING OF THE HEATING HOSE

In case of defect (of the heating conductor), protection against

an electric shock is secured by the protective earthing of the

heating hose. This earthing is implemented by the electric

supply to a shock proof socket

Be sure that the grounding of the shock

proof socket, to which the heating-hose will

be connected, is installed as prescribed and

functioning.

1.7

USE OF UNITS ON BUILDING SITES AND

WORKSHOPS

The unit may only be connected to the mains network via a

special feeding point with a residual-current device with INF

≤ 30 mA.

Wagner‘s accessories program also includes

a mobile operator protection device for the

electronic supply, which can also be used

with other electronical equipment.

1

SAFETY REGULATIONS FOR

AIRLESS SPRAYING

All local safety regulations in force must be observed.

The following sources are just a sample of those containing

safety requirements for Airless spraying.

a) The European Standard „Spray equipment for coating ma-

terials – safety regulations „ (EN 1953: 1998).

The safety regulations of the manufacturer of the Air-

less unit are to be observed in order to ensure safe han-

dling of the Airless high-pressure spraying unit.

Observe the following additional safety instructions during

operation with these specified heating-hoses:

1.2

EXPLOSION PROTECTION

Do not use the unit in work places which are

covered by the explosion protection regula-

tions.

The unit is not designed to be explosion pro-

tected.

1.3

DANGER OF EXPLOSION AND FIRE FROM

SOURCES OF IGNITION DURING SPRAYING

WORK

There must be no sources of ignition such as,

for example, open fires, lit cigarettes, cigars or

tobacco pipes, sparks, glowing wires, hot sur-

faces, etc. in the vicinity.

SAFETY REGULATIONS

1.8

HIGH PRESSURE HOSE

Attention, danger of injury by injection! Wear

and tear and kinks as well as usage that is not

appropriate to the purpose of the device can

cause leakages to form in the high-pressure

hose. Liquid can be injected into the skin

through a leakage.

High-pressure hoses must be checked thoroughly before

they are used.

Replace any damaged high-pressure hose immediately.

Never repair defective high-pressure hoses yourself!

Avoid sharp bends and folds: the smallest bending radius

is about 20 cm.

Do

not drive over

the high-pressure hose. Protect against

sharp objects and edges.

Never pull on the high-pressure hose to move the device.

Do not twist the high-pressure hose.

Do not put the high-pressure hose into solvents. Use only

1.1

FLASH POINT

Only spray coating materials with a flash point

of at least 5 kelvin higher than the set tem-

perature (minimum flash point is 21°C).

The flash point is the lowest temperature at

which vapors develop from the coating ma-

terial. These vapors are sufficient to form an

inflammable mixture over the air above the

coating material.

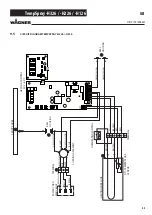

Electrostatic charging of spray guns and the high-pressure

hose is discharged through the high-pressure hose. For this

reason the electric resistance between the connections of the

high-pressure hose must be equal or lower than 1 MΩ.

The resistance of the TempSpray - H126 must be equal or low-

er than 2 Ohm.