23

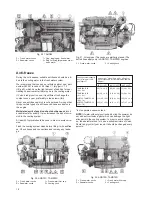

4. Lubricating-disengageable

clutch, reduction gear

Optional equipment, TAMD70D.

Lubricate the throw-out bearing (nipple 1) daily, before

starting.

NOTE! Lubricate sparingly, to avoid risk of excess grease

finding its way onto the dry clutch linings and causing slip.

Use multi-purpose heat resistant grease.

5. Checking oil level in reduction

gear

Optional equipment, TAMD70D

Check the level daily before starting.

The oil should be filled up to the level plug (7). Top-up with

oil if required. Regarding oil quality and viscosity, see table

below. Concerning oil changing, see page 28.

Lubricating oil for reduction gear

Clutch with

Oil grade

Visco-

Capacity,

reduction

sity

dm

3

/litres

gear

(qts.)

Rockford/BW

203 mm (8")

Engine oil

SAE 30

approx. 1 (1)

254 mm (10")

Engine oil

SAE 30

approx. 1.5 (1.5)

Twin Disc

Engine oil,

SAE 40

approx. 1 (1)

or Hypoid oil SAE 80

Every 50 hours

6. Lubricating-disengageable

clutch, reduction gear

Optional equipment, TAMD70D

Lubricate the inner support bearing (nipple 4) every 50

hours. Unscrew the plug (4) for Rockford/BW 203 mm (8")

power take-off with reduction gear. Use multi-purpose heat

resistant grease.

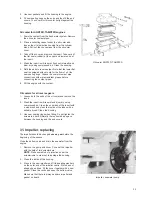

Extra power take-off at front end. Rockford/BW (1:1)

Extra power take-off at front end, Rockford/BW (2.8:1)

Extra power take-off at front end, Twin Disc (3:6:1)

Picture text for extra power take-offs at front end

1.

Nipple for throw-out

bearing

2.

Inspection cover

3.

Nipple for output shaft

bearing

4.

Nipple for support bearing

5.

Nipples (2 x) for disengage-

ment shaft

6.

Drain plug

7.

Level plug