22

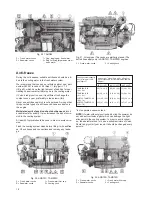

Reverse gear lubricating oil

Engine oil of same quality

Oil capacity, approx.

and viscosity as in

(incl. cooler)

engine*

dm

3

(litres)

Imp.gall.

USgall.

Borg Warner 73CR*

2.5

0.5

0.7

Borg Warner 10-05* V-drive

5.5

1.2

1.5

Twin Disc, MG 502

2.5

0.5

0.7

Twin Disc, MG 506

6.5

1.4

1.7

SCG MRF 350 HDMK3

12.5

2.7

3.3

* Oil viscosity for Borg Warner, SAE 30.

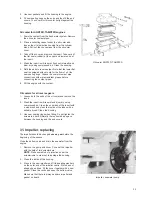

3. Engine coolant level

Check the level daily before starting.

NOTE! Open the coolant filler cap carefully when the

engine is hot.

For the TAMD60 engines fitted with a separate transparent

expansion tank the level should be between the ”max.” and

”min.” marks.

On other engines, when cold, the level should be approx. 5

cm below the sealing surface of the filler cap so that the

coolant can expand when the engine becomes warm.

When there is danger of frost, the system should be drai-

ned or anti-freeze added. See under ”Precautions in case

of frost”.

When filling the coolant, remember to open the air ven-

ting cocks in order to avoid air pockets. There is a ven-

ting cock on the water pipe at the turbo. For the 70-engines

there is also a venting cock situated at the front of the ther-

mostat housing.

On the TAMD60-engines, small quantities of coolant requi-

red for topping-up can be added to the expansion tank, but

otherwise the coolant should always be filled directly into

the heat exchanger through the hole for the hexagon plug

until the engine is completely full and air-vented. Then clo-

se the venting cock at the turbo and refit the hexagon plug

on the heat exchanger. Thereafter fill the expansion tank

with approx. 3 litres (0.7 Imp. gall.=0.8 US gall.) and refit

the cap.

If there is a separate transparent expansion tank this

should be filled last to slightly above the MIN-level, after

having first completely filled the engine’s expansion tank.

If the engine is connected to a heating radiator, this must

also be air-vented before the cap or plug on the heat ex-

changer are fitted. Otherwise the engine may be damaged

due to insufficient cooling.

If the engine runs abnormally hot, vent the cooling system

and top up with water.

Anti-corrosion additives should not be used since parts of

the cooling system are made of light-alloy.

The seawater filter (optional equipment) should be check-

ed daily. With regard to cleaning, see page 28.

Venting cocks

TAMD60

1.

Cap on expansion tank.

Topping-up.

2.

Hexagon plug on heat

exchanger. Filling.

Separate expansion tank

1.

Over-pressure cap

2.

Cover

3.

Max. level

4.

Min. level

5.

Hose from engine

6.

Hose with free end

TAMD70, AQD70