Vogt

®

VT Service Manual

6-3

Maintenance

Air-Cooled Condenser Cleaning.

Visual inspection will indicate if dirt is accumulating and clogging

the fin face of the condenser. A vacuum cleaner, compressed air, or a brush may be used to remove any

accumulation of loose dirt from the fin section of the condenser.

For the removal of more severe accumulations of dirt or foreign materials, a detergent-type cleaner can be

used. This cleaning agent can be supplied by your local refrigeration supply house. Follow the

manufacturer’s instructions when using a liquid cleaner.

If fins have been damaged, they should be straightened with the proper fin comb.

Compressor Oil.

In starting and charging the unit, the oil sight glass in the crankcase of the compressor

should be watched carefully for the first hour to make certain the proper lubrication is being maintained. The

oil may become low in the crankcase on an initial start-up if the electrical current has been interrupted to the

machine, thus de-energizing the compressor crankcase heater.

Before starting the machine again, the heater should be energized for a time period of at least two hours to

evaporate refrigerant that may have condensed in the crankcase during the shutdown period. If the oil level

is low after start-up, it should begin to return after a short period of operation.

The oil level should be checked frequently, particularly during the start-up operation, to see that a sufficient

amount of oil remains in the crankcase. While it is important to observe the oil splash during operation, the

true level can be obtained only when the compressor is stopped. With the compressor idle, the oil level

should be between 1/2 to 3/4 of the sight glass, but not above the top of the sightglass.

Although the machine was shipped with the oil charge, which was originally added for the test operation, it

may be necessary to add some oil when or if new refrigerant is added to the system.

An oil pump should be used to force any oil that may be required into the system. Oil may be added to the

compressor of all units through the compressor oil charging port. Air should be purged from the oil pump

discharge line by forcing some oil through the line before tightening the charging port.

R22 - Dual Inhibited Suniso 3GS (Viscosity 150) or equal.

R404A - Ultra 32 – 3MAF, Mobil EAL Arctic 22 CC or equal.

See page 3-1 for amount.

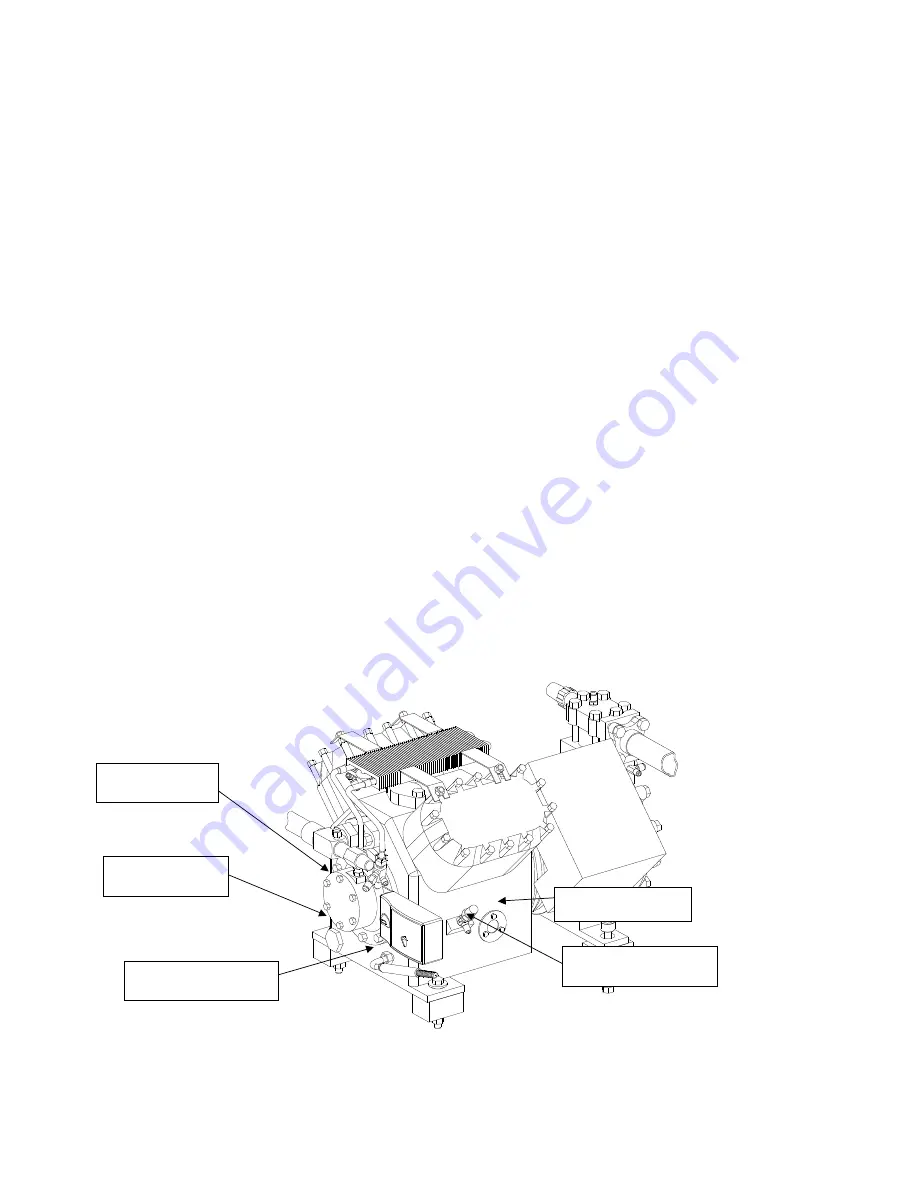

FIGURE 6-1

Copeland Discus Compressor (VT80)

Oil Sight Glass

Oil Charging valve

Oil Pump

Suction Screen

Crankcase Heater

Oil Pump

Summary of Contents for VT100

Page 1: ...VT Series Ice Maker Model VT40 VT60 VT80 VT100 Revision Date 1 04 12 ...

Page 21: ...2 14 Vogt VT Service Manual Installation Instructions Blank ...

Page 29: ...4 6 Vogt VT Service Manual Initial Startup Blank ...

Page 51: ...7 6 Vogt VT Service Manual Troubleshooting Blank ...

Page 71: ...8 20 Vogt VT Service Manual Service Operations Blank ...