45

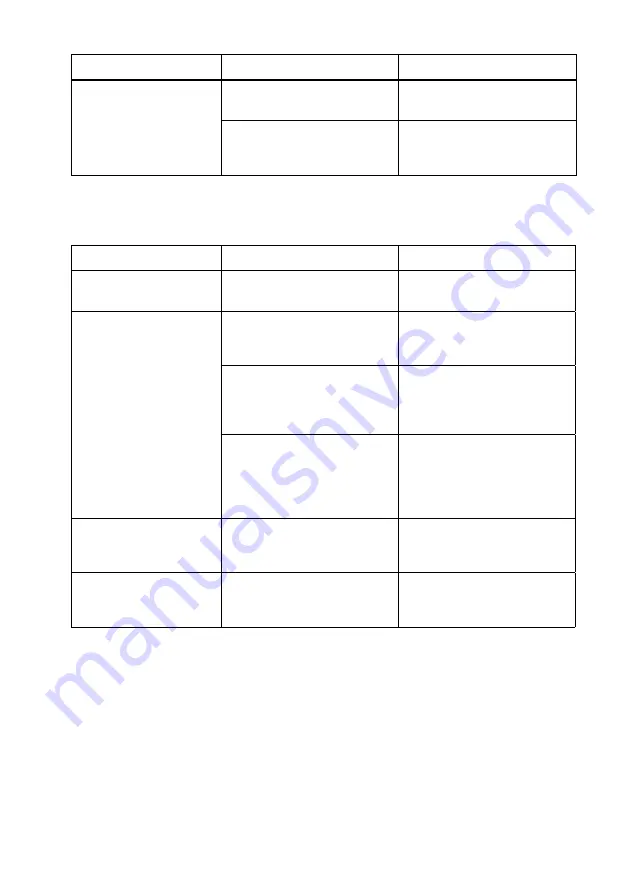

Problem

Possible causes

Corrective actions

The tube is not held

sufficiently by the front

chuck.

The front chuck jaws are worn.

Replace the three jaws of the

front chuck. (See page 39).

The front chuck jaw holders are

worn.

Replace the three jaw holders

of the front chuck. (See page

41).

Thread cutting problems

Problem

Possible causes

Corrective actions

The die head is hard to

insert correctly.

The head tilting spindle or the

receiving cylinder are fouled.

Clean the spindle and the

receiving cylinder.

The oil flow in the head is

insufficient.

The flow is badly regulated.

Increase the oil flow by turning

the flow regulating wheel. (See

page 21).

The oil system is fouled.

Remove turnings from the

scrap receiver and the oil filter

grid and clean the strainer. (See

page 34).

The oil level is insufficient.

Add oil supplied by Virax (see

page 9) by pouring it directly

into the container. (Minimum oil

level: half the diameter of the

strainer).

The oil is no longer clear.

The oil has been in use for too

long.

Drain the oil (see page 5) and

refill with oil supplied by Virax

(see page 9).

The oil flows out the back

of the tube.

The machine is not sloped

forward by the correct amount.

Position the machine on the

horizontal so that the 2° slope

is maintained. (See page 17).

EN

Summary of Contents for 162120

Page 1: ...Threading machine for tubes up to 2 Instruction Manual 162120 EN ...

Page 3: ...EN ...

Page 51: ...49 Exploded view of the motor and the oil pump Pump EN ...

Page 52: ...50 Exploded view of the transmission EN ...

Page 53: ...51 Exploded view of the saddle EN ...

Page 54: ...52 Exploded view of the automatic opening 2 die head EN ...

Page 55: ...53 Exploded view of the 1 4 3 8 die head EN ...

Page 56: ...54 Exploded view of the tube cutter EN ...

Page 58: ...56 Components of a nipple holder EN ...

Page 59: ...EN ...