14

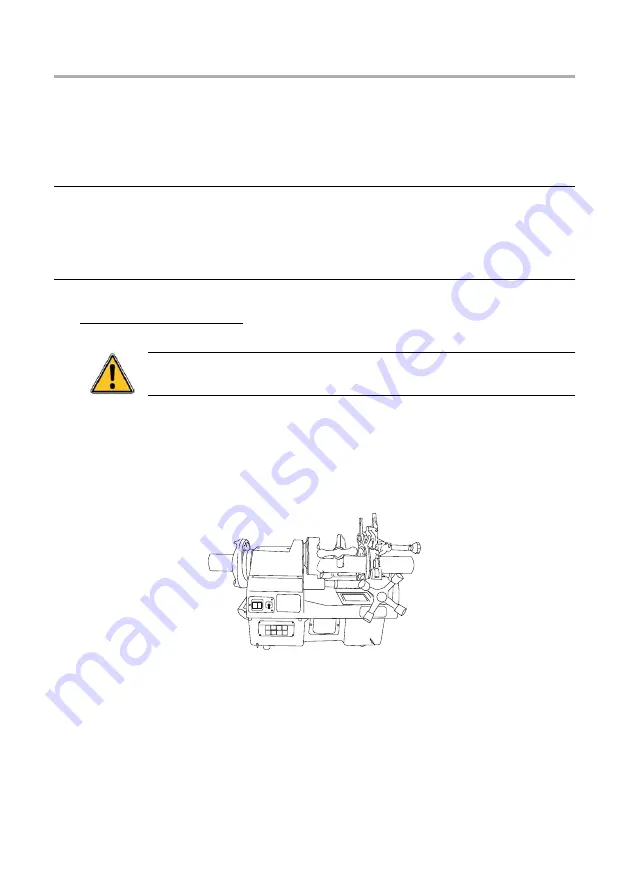

Moving and setting up the machine

There are three ways of moving the machine:

by a lifting device such as a hoist or winch

manually

on the Virax trolley especially designed for the 162120 threading machine (part no.

162160)

Important:

1) The oil tank must be drained before moving the machine any great distance.

2) Whatever method of transportation is used, the machine must always be transported with a

tube clamped between the chucks and the die head, the tube cutter lightly tightened against

the tube.

Moving by lifting equipment

Raise the die head (see pages 25 and 28 for the procedure for installing the various heads).

Warning:

Do not forget to do this as the die head is simply fixed to its shaft and

can therefore fall off during transport.

Use a 2” tube of sufficient length to overlap the two sides of the machine by about 30 cm.

Carefully ream each tube end to avoid the tube edges cutting the lifting cable (see page 20

for the reaming procedure).

Insert the tube into the machine and check that the ends leaving the machine are as equal in

length as possible and tighten both chucks. (See page 18 for instructions for mounting a

tube):

Place the tube cutter on the tube and tighten it so it is held firmly in place.

Pass the lifting cable through the tube and move the machine thus carried by the tube. (Once

the machine is suspended, you can, if necessary, unscrew the feet to facilitate transport):

–

–

–

●

●

●

●

●

●

EN

Summary of Contents for 162120

Page 1: ...Threading machine for tubes up to 2 Instruction Manual 162120 EN ...

Page 3: ...EN ...

Page 51: ...49 Exploded view of the motor and the oil pump Pump EN ...

Page 52: ...50 Exploded view of the transmission EN ...

Page 53: ...51 Exploded view of the saddle EN ...

Page 54: ...52 Exploded view of the automatic opening 2 die head EN ...

Page 55: ...53 Exploded view of the 1 4 3 8 die head EN ...

Page 56: ...54 Exploded view of the tube cutter EN ...

Page 58: ...56 Components of a nipple holder EN ...

Page 59: ...EN ...