44

Diagnostics and fault fixes

Important:

If you encounter problems not on this list, contact Virax or their representative for the

problem to be dealt with by After-Sales service.

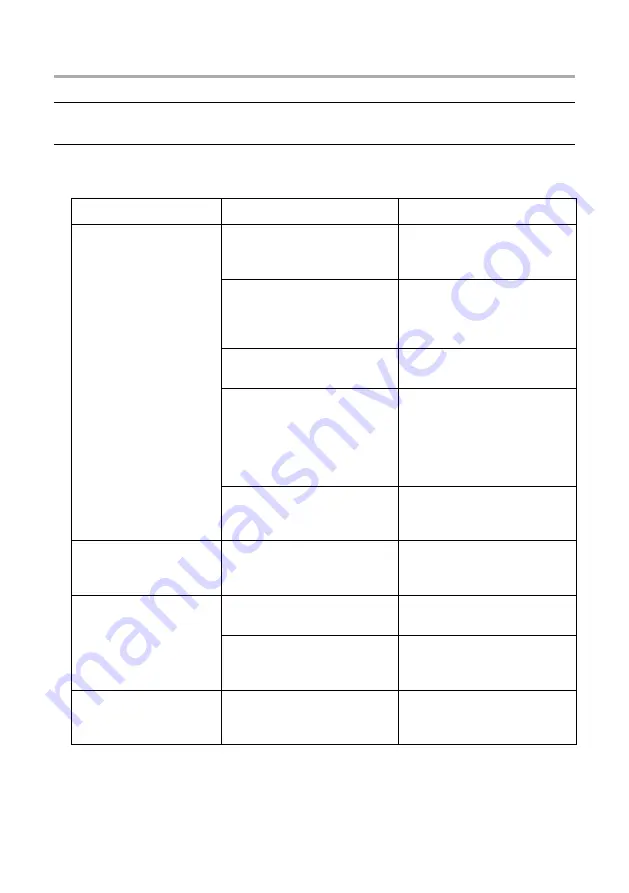

Machine operating problems

Problem

Possible causes

Corrective actions

The motor does not

operate when the start

button is pressed.

The power socket is not

connected to the electrical

power supply.

Connect the socket to the

electrical power supply.

The power supply voltage is too

low.

Check the voltage delivered by

the electrical power supply.

(The voltage must not be less

than 150 V).

The motor brushes are worn.

Replace the brushes by new

ones (see page 35).

The start button is not working.

Replace the button. (Warning:

do not short circuit the start

button; see page 8, “Attention”,

concerning the machine being

restarted after an unexpected

stop).

The motor is burnt out.

Contact Virax or their

representative to change the

motor.

The machine shaft is not

driven by the motor.

The transmission is broken.

Contact Virax or their

representative to change the

transmission.

The shaft rotation is slow

or irregular.

The power supply voltage is too

low.

Check the supply voltage. (It

must not be less than 150 V).

The transmission is defective.

Contact Virax or their

representative to change the

transmission.

There is forward and

backward play in the

motor spindle.

The rear chuck retaining collar

is not sufficiently tight.

Tighten up the main shaft blind

collar. (See page 36).

EN

Summary of Contents for 162120

Page 1: ...Threading machine for tubes up to 2 Instruction Manual 162120 EN ...

Page 3: ...EN ...

Page 51: ...49 Exploded view of the motor and the oil pump Pump EN ...

Page 52: ...50 Exploded view of the transmission EN ...

Page 53: ...51 Exploded view of the saddle EN ...

Page 54: ...52 Exploded view of the automatic opening 2 die head EN ...

Page 55: ...53 Exploded view of the 1 4 3 8 die head EN ...

Page 56: ...54 Exploded view of the tube cutter EN ...

Page 58: ...56 Components of a nipple holder EN ...

Page 59: ...EN ...