19

Checking with a high ohm scale, if the high voltage capacitor is normal, the meter will indicate conti-

nuity for a short time and should indicate approximately 10 M

Ω

once the capacitor is charged. If the

above is not the case, check the capacitor with an ohmmeter to see if it is shorted between either of

the terminals and case. If it is shorted, replace the capacitor.

E

PRIMARY INTERLOCK SWITCH AND THIRD DOOR SWITCH TEST

Isolate the switch and connect the ohmmeter to the common (COM.) and normally open (NO) terminal

of the switch. The meter should indicated an open circuit with the door open and a closed circuit with

the door closed. If improper operation is indicated, replace the switch.

F

SECONDARY INTERLOCK SYSTEM TEST

DOOR SENSING SWITCH

Isolate the switch and connect the ohmmeter to the common (COM.) and normally open (NO) terminal

of the switch. The meter should indicated an open circuit with the door open and a closed circuit with

the door closed. If improper operation is indicated, replace the door sensing switch.

SECONDARY INTERLOCK RELAY

Disconnect two (2) wire leads from the tab terminal of the secondary interlock relay (RY2). Check the

state of the relay contacts using a ohmmeter. The relay contacts should be open. If the relay contacts

are closed, replace the circuit board entirely or the relay itself.

G

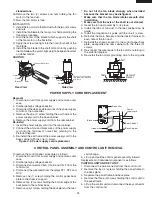

MONITOR SWITCH

Disconnect the oven from power supply.

Before performing this test, make sure that the primary interlock switch and the secondary interlock

relay are operating properly, according to the above Test Procedures. Disconnect the wire lead from the

monitor switch (NC) terminal. Check the monitor switch operation by using the ohmmeter as follows.

When the door is open, the meter should indicate a closed circuit. When the monitor switch actuator

is pushed by a screw driver through the lower latch hole on the front plate of the oven cavity with the

door opened (in this condition the plunger of the monitor switch is pushed in), the meter should indi-

cate an open circuit. If improper operation is indicated, the switch may be defective. After testing the

monitor switch, re-connect the wire lead to the monitor switch (NC) terminal and check for continuity

of monitor circuit.

H

TEST PROCEDURES

PROCEDURE

LETTER

COMPONENT TEST

SCREW DRIVER

MONITOR SWITCH

OHMMETER

PRIMARY

INTERLOCK

SWITCH

COM.

N.C.

C/T FUSE TEST

A continuity check across the C/T fuse terminals should indicate a closed circuit unless the temperature

of the C/T fuse reaches approximately 266

O

F(130

O

C). An open C/T fuse indicates overheating of the

magnetron. Check for restricted air flow to the magnetron, especially the cooling fan air guide.

CAUTION: IF THE TEMPERATURE FUSE INDICATES AN OPEN CIRCUIT AT ROOM

TEMPERATURE, REPLACE TEMPERATURE FUSE.

If the C/T fuse is blown when the door is opened, check the secondary interlock relay, primary interlock

switch and monitor switch according to the "TEST PROCEDURE" for those switches before replacing

the blown monitor fuse.

CAUTION: BEFORE REPLACING A BLOWN C/T FUSE, TEST THE SECONDARY INTERLOCK RELAY,

PRIMARY INTERLOCK SWITCH, DOOR SENSING SWITCH AND MONITOR SWITCH

FOR PROPER OPERATION.

If the C/T fuse is blown by improper switch operation, the C/T fuse and monitor switch must be replaced

with "C/T fuse and monitor switch assembly" part number FFS-BA019/KIT, even if the monitor switch

operates normally. The C/T fuse and monitor switch assembly is comprised of a 20 ampere fuse and

switch.

Summary of Contents for VMOC206SS

Page 3: ...3 Notes...