7

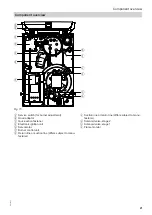

Fig. 2

Oil pump make: Danfoss

Fig. 3

Oil pump make: Suntec

0

1.

Switch system OFF at mains isolator and safe-

guard against unauthorised reconnection.

0

2.

Unscrew plug "P"

A

from the oil pump.

0

3.

Unscrew plug "V"

B

from the oil pump.

Note

Oil may leak from the oil pump when doing this.

0

4.

Insert a pressure gauge (measuring range 0 -

40 bar) and a vacuum gauge (measuring range 0 -

1 bar).

Note

Only seal in the pressure and vacuum gauges with

copper or aluminium gaskets or with O-rings.

Never use sealing tape.

0

5.

Start the burner.

Note

The solenoid valve opens.

0

6.

Read off the oil pressure and the vacuum of the

pump on the relevant gauge (vacuum should be

max. 0.35 bar at a height differential of 3 m

between the oil pump and the bottom of the tank).

Note

If the vacuum pressure is higher than 0.35 bar,

check the filter for contamination and check the

pipe run.

E

Fig. 4

0

7.

Should the CO

2

value fall outside the range of 13

to 14 % by vol., adjust the CO

2

value by regulating

the oil pressure.

Note

Subject to pump type, the pressure adjusting

screws may be located at the front or on the side

of the oil pump.

■

For burner stage 2, set the oil pressure at pres-

sure adjusting screw

D

. The service switch

E

is factory-set to setting 2.

■

For burner stage 1, set service switch

E

to set-

ting 1; open the flap to do so. Adjust the oil pres-

sure by means of pressure adjusting screw

C

.

Clockwise turn

→

pressure increases.

Anti-clockwise turn

→

pressure decreases.

Note

For standard values for burner settings, see page.

Commissioning, inspection, maintenance

Checking the oil pressure and vacuum , adjusting…

(cont.)

5831447