45

5584 109 - 10

Vitocrossal 200 CM2 186 to 311 Service

Burner Control Unit

Burner Control Unit

(continued)

Configurations:

Menu item

Description

5

Changeover from the operating display of the burner control unit phase to other process information

6

Configuration of control function operating parameters

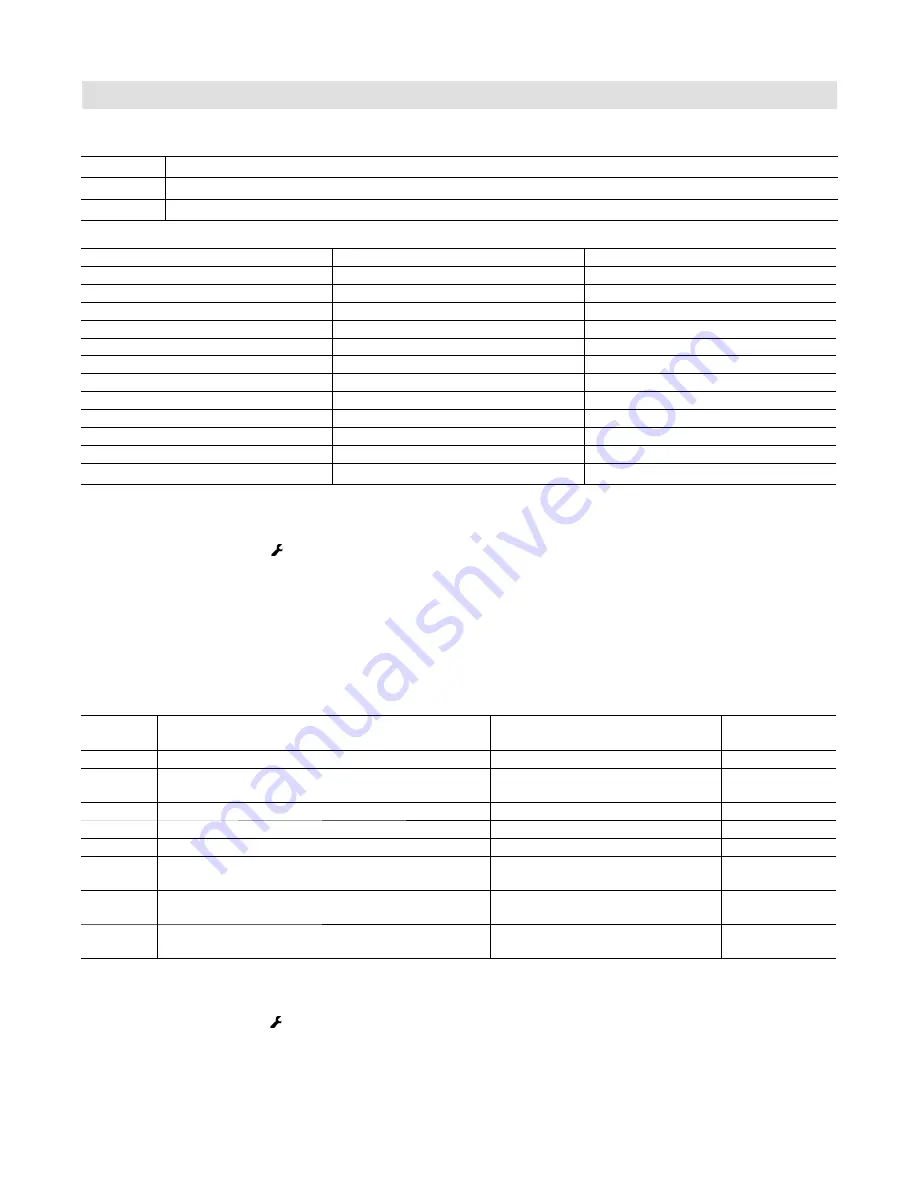

Menu item “5“ is used to display the following process information:

Sub-menu Item

Process Information

Units/Scale

0

Phase

1

1

Boiler water temperature

*1

°C

2

Flue gas temperature

*1

°C

3

Ionization current

I in 1/10

μ

A

4

Set speed

%

5

PWM manipulated variable

%

6

Actual speed

RPM x10/min

7

Gas pressure switch 1

0 or 1

8

Gas pressure switch 2

*1

0 or 1

9

Air pressure switch

0 or 1

A

Gas valve 1

0 or 1

b

Gas valve 2

*1

0 or 1

1.

S

longer than 2 seconds “ “

flashes.

2.

Y

until “5“ is shown under Service.

3.

S

“5“ will be displayed under Status

4.

Y

until “3“ is shown under Service.

5.

S

“3“ is shown under Status and during operation

the ionization current is shown under Service

(e.g. 30 = 3.0

μ

A).

*1

Not available for all boiler types, check at control unit if required.

Menu item “6“ is used to change the following operating parameters:

Sub-menu

Item

Parameter

Units/Scale

Delivered

condition

1

Maximum operational input

% of rated input

100%

2

Gas type

0=NG (natural gas)

1=LPG (liquid propane gas)

3

Not assigned

--

--

4

Maximum boiler water temperature

from 41 to 260°F (5 to 127°C)

203°F (95°C)

5

Integral threshold value of controller

In Kmin from 1 to 255

30 Kmin

6

Runtime optimization

0=minimum pause

1=integral method

1

7

Motorized vent damper

0=without damper

1=with damper

0

0

Reset all operating parameters to their delivered

condition

--

--

6. To exit the process information menu, press and

hold

S

longer than 2 seconds “_“

flashes.

7.

Y

until “5“ is shown under Service.

8.

S

“5“ will be displayed under Status

9.

B

until “0“ is shown under Service.

10.

S

to change to the operating display.

1.

S

longer than 2 seconds “ “ flashes.

2.

Y

until “6“ is shown under Service.

3.

S

“6“ will be displayed under Status and the current

value for the maximum operational output in % is

shown under Service.

4.

Y

/

B

for required maximum operational output.

5.

S

to confirm. If applied successfully, “1“ will be

shown under Service, “0“ if it failed.

6.

S

to change to the operating display.

7.

R

to reset unit and apply settings.

Example: to display the ionization current, press the following keys:

Example:

to set the maximum operational burner input to between 0 and 100%, press the following buttons: