7

Defiant

®

1610CE Non-Catalytic Woodburning Stove

30003846

c) Mild steel fluepipes complying with BS 1449: Part 1:

1991, with a flue wall thickness of at least 3 mm;

d) Cast iron fluepipes complying with BS 41: 1973

(1998).

Flue Pipes with a spigot and socket joint should be

fitted with the socket facing upwards, to contain con-

densates and moisture within the flue. Joints should be

made gas tight using proprietary jointing accessories,

or, where appropriate, by packing joint with noncombus-

tible rope and fire cement.

Single-wall connectors should be made of 4 gauge

or heavier steel. Do not use galvanized connector; it

cannot withstand the high temperatures that can be

reached by smoke and exhaust gases, and may release

toxic fumes under high heat. The connector may be

15 mm (6”) or 03 mm (8”) in diameter.

If possible, do not pass the chimney connector through

a combustible wall or ceiling. If passage through a com-

bustible wall is unavoidable, refer to the section on Wall

Pass-Throughs. Do not pass the connector through an

attic, a closet or similar concealed space. The whole

connector should be exposed and accessible for in-

spection and cleaning.

In horizontal runs of un shielded chimney connector,

maintain a distance of 76 mm (30”) from the ceiling.

Keep it as short and direct as possible, with no more

than two 90° turns. Slope horizontal runs of connector

upward 6mm per meter (1/4” per foot) going from the

stove toward the chimney. The recommended maximum

length of a horizontal run is 914 mm (36”), and the total

length should be no longer than .4 m (8’). In cathedral

ceiling installations, extend the prefabricated chimney

downward to within .4 m (8’) of the stove. This will help

maintain a good draft by keeping the smoke warm, so

that it rises readily.

Wear gloves and protective eyewear when drilling, cut-

ting or joining sections of chimney connector.

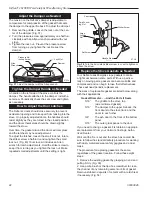

Single-wall chimney connectors

•

Begin assembly at the flue collar of the stove. Insert

the first crimped

end into the stove’s

flue collar, and

keep each crimped

end pointing toward

the stove. (Fig. 4)

Using the holes

in the flue collar

as guides, drill 3

mm (1/8”) holes

in the bottom of

the first section of

chimney connector

and secure it to the

flue collar with three #10 x 1/” sheet metal screws.

Lift off the griddle, and shield the stove’s surface

between the griddle opening and the front of the flue

collar to protect the finish when you drill the front

hole.

•

Fasten each joint between sections of chimney

connector, including telescoping joints, with at least

three (3) sheet metal screws. The pre-drilled holes in

the top of each section of chimney connector serve

as guides when you drill 3 mm (1/8”) holes in the

bottom of the next section.

•

Fasten the chimney connector to the chimney.

Instructions for various installations follow. Figure 6

illustrates the general layout of chimney connector

parts.

•

Be sure the installed stove and chimney connector

are correct distances from nearby combustible mate-

rials.

NoTe:

Special slip pipes and thimble sleeves that form

telescoping joints between sections of chimney con-

nector are available to simplify installations. They often

eliminate the need to cut individual connector sections.

Consult your local dealer about these special pieces.

Securing the Single-wall connector to a

prefabricated chimney

Follow the installation instructions of the chimney manu-

facturer exactly as you install the chimney. The manu-

facturer of the chimney will supply the accessories to

support the chimney, either from the roof of the house,

at the ceiling of the room where the stove is installed, or

from an exterior wall.

Special adapters are available from your local dealer to

make the connection between the prefabricated chim-

ney and the chimney connector. The top of such adapt-

ers attaches directly to the chimney or to the chimney’s

ceiling support package, while the bottom of the adapter

is screwed to the chimney connector.

These adapters are designed so the top end will fit out-

side the inner wall of the chimney, and the bottom end

will fit inside the first section of chimney connector.

Securing the Single-wall connector to a

Masonry chimney

Both freestanding masonry chimneys and fireplace

masonry chimneys may be used for your installation.

Freestanding installations

If the chimney connector must pass through a com-

bustible wall to reach the chimney, follow the recom-

mendations in the Wall Pass-Through section that

follows. The opening through the chimney wall to the

flue (the “breech”) must be lined with either a ceramic or

metal cylinder, called the “thimble”, which is cemented

ST242

Chimney connector

12/13/99 djt

Flue Gas

Direction

Toward

Stove

ST4

Fig. 4

Chimney connector.