Fitting Type 1 - Bayonet

l

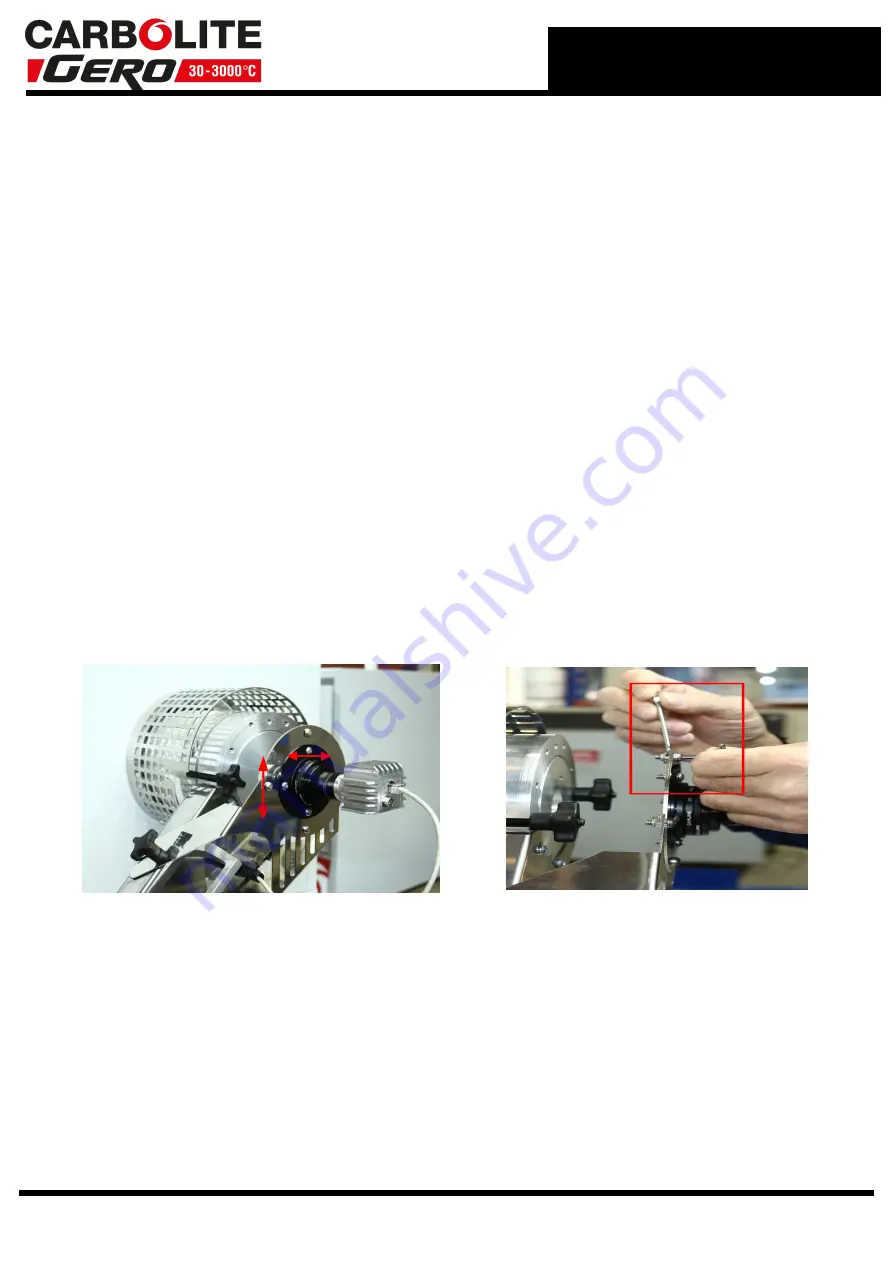

Mount the lens and camera assembly (fig 5b) onto the camera mounting bracket as

shown in fig 5e and 5f.

l

Rotate the lens and camera assembly anti-clockwise to locate in position. The socket

head screws are fixed in position and do not require tightening.

l

Ensure that the camera is in a horizontal position.

l

To rotate the camera independently of the lens, hold the camera firmly in position

and use a 1.25 mm Allen key to loosen the three grub screws positioned around the

adapter ring as shown in fig 5b, and position the camera horizontally.

l

Once the camera is in the correct position, tighten the three grub screws and release

the camera.

l

Connect the Ethernet cable from the front of the door arm to the Ethernet socket on

the rear of the camera. See fig 11a.

Fitting Type 2 - Screw

l

Mount the lens and camera assembly onto the camera mounting bracket as shown

in fig 5e and 5f.

l

Secure the camera assembly in place with the four nuts and socket head screws

provided.

l

Screw the nuts onto the screw threads by hand, then hold them in place using an 8

mm spanner.

l

Tighten the screws using a 3 mm Allen key.

l

To adjust the positioning of the camera, loosen the outer screws to allow vertical

movement, or the inner screws to allow movement horizontally.

Horizontal and Vertical Adjustment

Securing Camera Assembly

3.9.1

Camera and Lens Settings

1. The camera settings are pre adjusted in the software to give the best image qual-

ity and should not need any additional further adjustment.

2. The lens is manually adjusted to give the best quality picture in the following way:

l

Focusing ring on the front of the lens, see fig 5b.

l

Aperture adjustment, see fig 5b. The ideal position for the aperture is at f16. At this

position exposure will be maintained between 450 °C (with rear lighting) and 1600

°C. If a specific test temperature range is be utilised i.e. maximum temperature set

19

Summary of Contents for CARBOLITE GERO CAF G5

Page 63: ...Fig 3 Front Tube Seal Assembly Fig 4 Door Arm Assembly 63 ...

Page 64: ...Fig 5a Camera Mounting Bracket Fig 5b Lens and Camera Assembly 64 ...

Page 65: ...Fig 5c Sliding the Camera Mounting Bracket Assembly onto the Door Arm 65 ...

Page 66: ...Fig 5d Securing the Camera Mounting Bracket Assembly to the Door Arm 66 ...

Page 67: ...Fig 5e Mounting the Lens and Camera Assembly 67 ...

Page 68: ...Fig 5f Lens and Camera Assembly in Position 68 ...

Page 69: ...Fig 6a Rear View of the Standard CAF G5 Furnace Showing Brick Box Assembly 69 ...

Page 71: ...Fig 7 Front Tube Seal Position 71 ...

Page 72: ...Fig 8 Tube End Seal Assembly Tightening Sequence Fig 9 Work Tube Front Support 72 ...

Page 73: ...Fig 10 Fitting the Door Arm Assembly Fig 10a Adjusting the Door Arm Assembly 73 ...

Page 74: ...Fig 11a Furnace Case and Controls 74 ...

Page 75: ...Fig 11b Gas Inlet Pipe Fig 12 Positioning the Furnace 75 ...

Page 77: ...Fig 13c Loading Samples into the Work Tube 77 ...

Page 78: ...Fig 16 File Folder 78 ...

Page 79: ...Fig 17 Door Arm Assembly Exploded View 79 ...

Page 82: ...SST DT HT FT Fig 18 Report Sheet Page 2 Side View Plan View Fig 19 Formed Wire Sample 82 ...

Page 83: ...Fig 20 Sample Carrier Sample Tiles and Sample Positions 83 ...

Page 84: ...Fig 21a Coal and Coke Test Piece Mould Fig 21b Biomass Test Piece Mould and Hand Press 84 ...

Page 85: ...Fig 22 Sample Loading Tool Fig 23 Camera Ethernet Connection 85 ...

Page 86: ...Fig 24 LED Driver Connection 86 ...

Page 87: ...Notes Service Record Engineer Name Date Record of Work ...