GENERAL OPERATION

Operation - 25

F

RONT

A

UXILIARY

C

OUPLERS

EQUIPMENT DAMAGE!

Dirt and other debris in hydraulic system can

cause damage to the system. Wipe clean the

mating parts of the couplers before coupling.

Use protective rubber plugs over hydraulic

couplers when not in use.

If attachment requires auxiliary hydraulics, couple the

attachment hoses with the front auxiliary couplers. This

is done by sliding the collar of the coupler rearward

and inserting the end of the attachment hose into the

coupler and releasing the collar. If the collar will not

snap forward on its own, pull it forward manually.

The couplers that the hoses are attached to will

affect which way the secondary S.D.L.A. lever is

pushed to control the action of the attachment. If

the hoses are connected and the action is not the

desired motion, then switch the hoses the couplers

are attached to. Auxiliary couplers are controlled by

moving the secondary S.D.L.A. lever left or right.

NOTE: Pressure build-up in the attachment hose

and on the power unit couplers may occur, causing

dif

fi

cult installation of hoses. If hoses do not easily

connect, try one or both of the following steps: 1)

To release the pressure from power unit couplers,

turn off engine and move the secondary lever of

the S.D.L.A. right and left to release pressure in the

power unit’s hydraulic circuit.

2) To release pressure in the attachment hose,

loosen one of the hose ends, tighten when pressure

is released.

W

EIGHT

T

RANSFER

(O

PTIONAL

A

CCESSORY

)

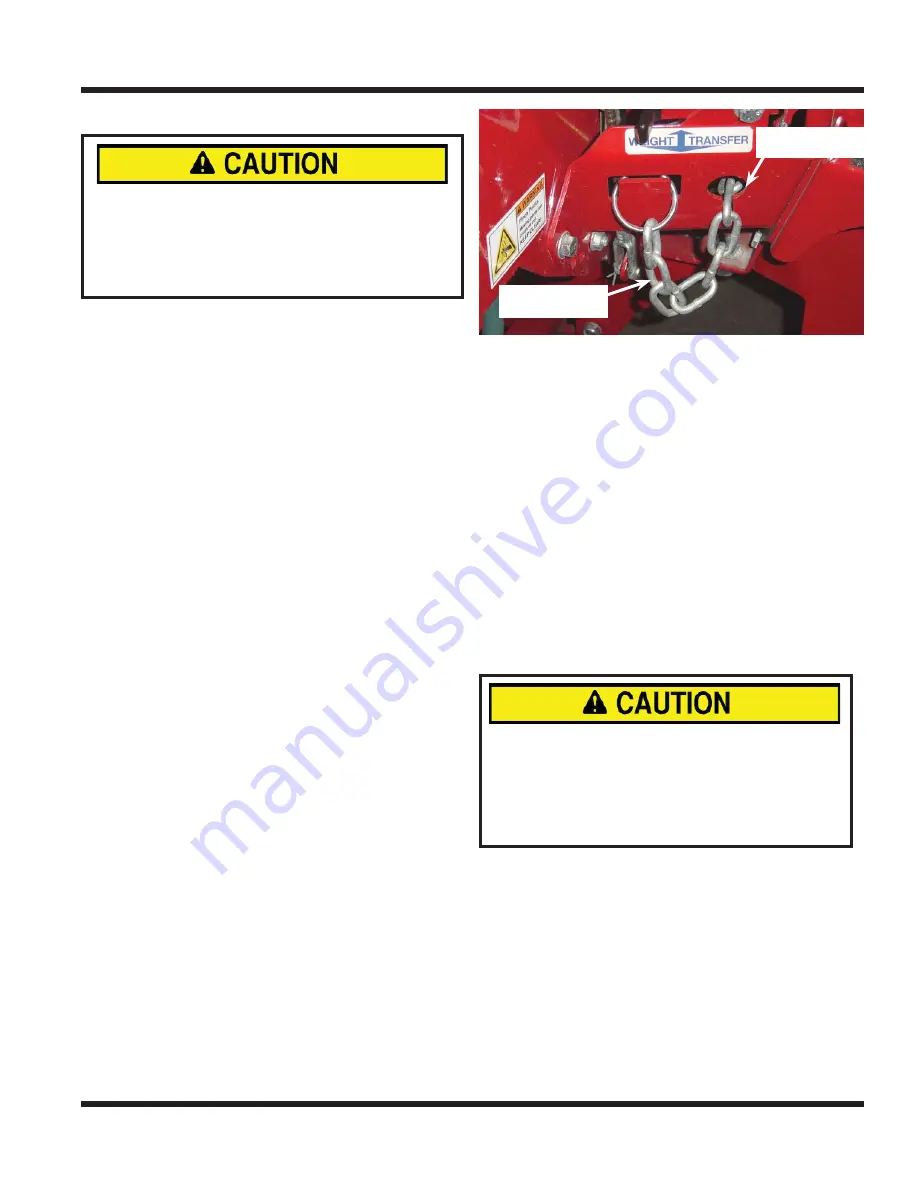

The weight transfer system transfers weight from the

attachment to the front wheels of the power unit. The

operator can select different transfer rates by adjust-

ing the right and left weight transfer chains.

To set the weight transfer, raise the front hitch to its

maximum height.

Weight Transfer

Weight Transfer

Chain

Chain

Weight Transfer

Weight Transfer

Chain Lock

Chain Lock

Lift the weight transfer chain link out of the chain

lock slot. Feed the chain back through the hole to

decrease amount of transferred weight or pull the

chain out through the hole to increase the amount

of transferred weight. When the desired setting is

reached, insert chain link back in the chain lock slot.

Selecting the proper amount of weight to transfer

depends on attachments, ground conditions and

operator preference. A lightweight attachment (e.g.

KA160 Power Blower) will not go down with full

weight transfer on. With full weight transfer on and

mowing in the

fl

oat position, the mower may not

come down quickly enough when going through

uneven terrain. Weight transfer must be reduced or

speed must be lowered.

H

IGH

/L

OW

R

ANGE

Never shift while under load, while moving, or

while on a slope. Always ensure the shift handle

is secured in the lock position at the end of each

shift stroke.

For slopes greater than 15 degrees, always

use low range.

Low range is recommended for most pulling, push-

ing, and slow travel. High range is ideal for transport

and light duty tasks.

Stop the power unit and engage the parking brake.

Move the shift lever to the desired range setting.

Occasionally engagement of the transaxle gears is

prevented by gear misalignment. Moving the steer-

ing wheel slightly to the right or left will move the

gears enough to complete the engagement.

GENERAL OPERATION