C-3

11/2007

* NOTE: WHEN ORDERING FOAMED CABINET ASSEMBLY OR BASE COVER PANEL, PLEASE

PROVIDE

9- CODE

AND

MANUFACTURER’S DATE CODE

.

FOR A COMPLETE LIST OF HARNESSES, PLEASE SEE PAGE C-10.

CABINET ASSEMBLY

ITEM NO DESCRIPTION

QTY PART NO

1

FOAMED CABINET

1

*

2

CABINET LATCH

3

1130807

3

SCREW, #10 X 3/8” CR TAP

11

V802212

4

RAMP ASSEMBLY

1

1133925

RAMP, DOOR

1

1130868

THUMB SCREW, 1/4-20 X .5, RAMP

1

1127060

5

LEVELING BOLT

4

1059902

6

BASE COVER PANEL

1

*

7

REFRIGERATION ASSEMBLY (SEE PAGE C-4)

1

~

8

CHANNEL-TRAY SUPPORT

2

1126639

9

LIGHT ASSEMBLY (SEE PAGE C-5)

1

~

10

ANGLE MOUNT, VERTICAL PANEL

3

1131149

11

AIR DUCT ASSEMBLY

1

1127962

12

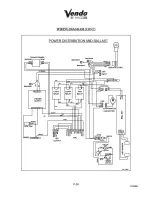

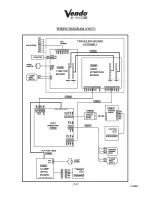

POWER DISTRIBUTION ASSEMBLY (SEE PAGES C6-C9)

1

~

13

VERTICAL FOAM PANEL

1

1133699

14

PANEL,SCREEN,REAR,41.5”

1

1146906

PANEL,SCREEN,REAR,34”

1

1148771

15

#10 X 1/2” SELF DRILLLING SCREW

4

V801489

Summary of Contents for VUE 30

Page 1: ......

Page 2: ...i 01 2008 TABLE OF CONTENTS...

Page 5: ......

Page 6: ......

Page 7: ......

Page 8: ......

Page 9: ......

Page 10: ......

Page 11: ......

Page 12: ......

Page 13: ......

Page 14: ......

Page 15: ......

Page 16: ......

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ...CL 1 04 2005 CLEANING INFORMATION SECTION...

Page 33: ...CL 4 04 2005 NOTES...

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......

Page 61: ......

Page 62: ...C 1 11 2007 CABINET SECTION...

Page 63: ...C 2 11 2007 1 2 3 4 5 6 3 7 8 9 10 11 10 10 13 12 14 15...

Page 67: ...C 6 11 2007...

Page 69: ...C 8 11 2007...

Page 72: ...C 11 11 2007 NOTES...

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......

Page 93: ......

Page 94: ......

Page 95: ......

Page 96: ......

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ......

Page 101: ......

Page 102: ......

Page 103: ......

Page 104: ......

Page 105: ......

Page 106: ......

Page 107: ......

Page 108: ......

Page 109: ......

Page 110: ......

Page 111: ......

Page 112: ...T 1 04 2005 TROUBLESHOOTING SECTION...

Page 125: ...T 14 04 2005 NOTES...