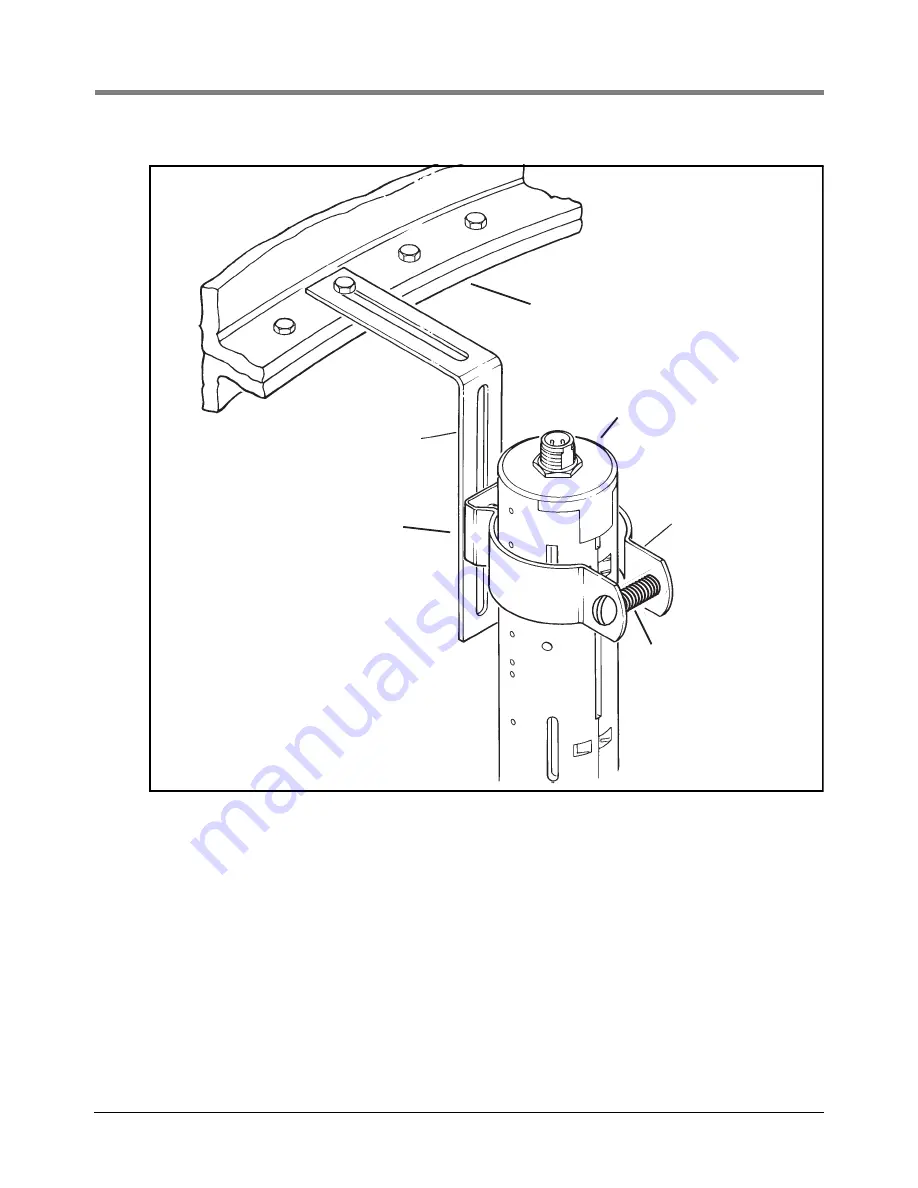

Appendix A: Universal Sensor Mounting Kit

Mounting Sensors

A-7

Figure A-7. Mounting the Sensor in a Containment Sump

Cl

a

mp

L-

b

r

a

cket

S

en

s

or

Cont

a

inment

su

mp

w

a

ll

s

en

s

or

s

\

s

ncntmnt.ep

s

1/4-20 x 3/4 hex

b

olt

w/ w

as

her

a

nd n

u

t

(not

s

hown)

1/4-20 x 1-1/2

m

a

chine

s

crew w/

w

as

her

a

nd n

u

t