Formular-Nr.:51 Rev.-Nr.:10 01/18

- 8 -

VARIPROP REMOVAL

VARIPROP removal after 1 or 2 seasons.

1.)

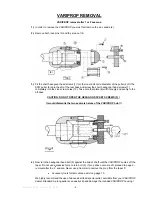

In order to remove the VARIPROP you must first remove the zinc anode (2).

2.)

Remove both lock pins (3) and the prop nut (4)

3.)

Fit the short hexagonal head screws (7) into the inner bolt circle diameter of the puller (6).Fit the

SPW puller (6) onto the aft of the rear boss and screw the short hexagonal head screws (7)

completely into the zinc screw holes (10). Take care that plate (6) will fit snugly and evenly to the

aft boss.

CAUTION: DO NOT OPEN THE HEXAGON SOCKET SCREWS (5) !

It would dismantle the two separate halves of the VARIPROP hub !!!

4.)

Now turn the hexagonal head bolt (9) against the end of shaft until the VARIPROP comes off the

taper. Do not use excessive force to turn bolt (9). If prop does not come off, proceed to page 9 –

removal after the 3

rd

season. Never use a hammer to remove the prop from the taper !!!

necessary tools for removal see servicing page 10.

We highly recommend the use of above described special puller, available from your VARIPROP

dealer. Standard 3-prong pullers can easily slip and damage the rounded VARIPROP housing !